Mung bean harvesting huller

A peeling machine and mung bean technology, which is applied to harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of wasting resources, difficult mung bean harvesting, and single function, so as to save food, save time and effort in collection, and avoid grinding pressure effect

Inactive Publication Date: 2019-01-22

王天宇

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

As a kind of coarse grain, mung bean is sweet and cool in nature and has the effects of clearing away heat and detoxification, relieving heat and benefiting water. However, the harvest of mung bean is very difficult. In order to reduce the waste of mung bean, farmers often use manual pulling, which is time-consuming and laborious

However, the existing mung bean harvesters have a single function and are only suitable for upright mung beans. Due to the weather, the lodging mung beans cannot be harvested, and many harvesters need a tractor to pull the front end, causing crushing on the mung beans and wasting resources.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

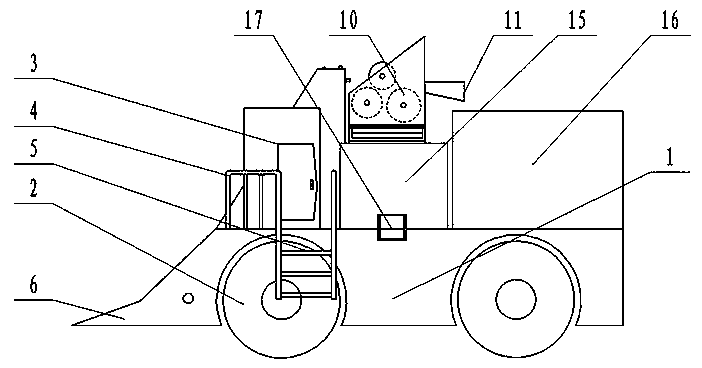

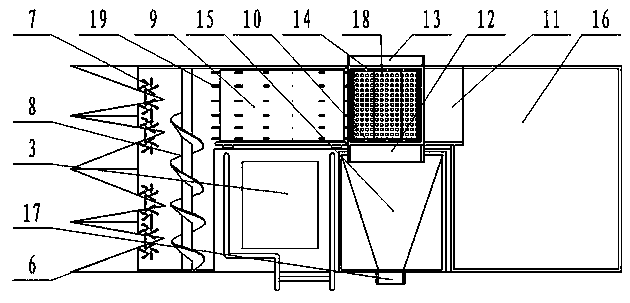

The invention discloses a mung bean harvesting huller, comprising a vehicle body, a harvesting device, a hulling device, and a collecting device, wherein the vehicle body includes a frame, traveling wheels, a cab, a guardrail, and a ladder; the harvesting device includes plant divider covers, arc rotating tools, a spiral spindle, and a conveyer belt; the hulling device includes hulling rollers, astalk outlet, a first mung bean outlet, a residue outlet, and a screen; the collecting device includes a mung bean collecting channel, and a stalk collecting channel; the plant divider cover is positioned at the frontmost end of the frame; the arc rotating tools are mounted pairwise between the plant divider covers; the spiral spindle is mounted behind the arc rotating tools; the cab is arranged behind the left of the spiral spindle; the conveyer belt is arranged behind the right of the spiral spindle; the bottom of the mung bean collecting channel is provided with a second mung bean outlet. The mung bean harvesting huller has the advantages that the pairs of the arc rotating tools allow lodged mung bean stalks to be harvested, grains are saved; the synchronization of harvesting, hulling and collecting enables time and manpower to be saved; the harvesting device is positioned at the front end of a tractor, so that it is avoided that the tractor rolls mung bean.

Description

technical field The invention belongs to the technical field of agricultural machinery, and in particular relates to a mung bean harvesting and peeling machine. Background technique As a kind of coarse grain, mung bean is sweet and cool in nature and has the effects of clearing away heat and detoxification, relieving heat and benefiting water. However, it is very difficult to harvest mung bean. In order to reduce the waste of mung bean, farmers often use manual pulling, which is time-consuming and laborious. However, the existing mung bean harvesters have a single function and are only suitable for upright mung beans. Due to the weather, the lodging mung beans cannot be harvested. Moreover, many harvesters require a tractor to be pulled at the front end, which causes crushing of the mung beans and wastes resources. Therefore, the solution to the above problems is particularly important. Contents of the invention The present invention overcomes the deficiencies of the pri...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A01D45/22A01D41/04A01D41/12A01D57/01

CPCA01D45/22A01D41/04A01D41/12A01D57/01

Inventor 王天宇

Owner 王天宇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com