Preloading construction method of a cross beam support of a bridge tower column

A beam support and construction method technology, which is applied in the field of bridge engineering and bridge tower column beam support preloading construction, can solve the problems of heavy workload and difficult construction, and achieve the effects of simple construction, unique method and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Such as Figure 4 As shown, the dimensions of the beam 2 between the two pylons 1 of the cable-stayed bridge in this embodiment are: beam length a=6.0m, beam width b=3.0m, beam height h=2.0m. Beam 2 is 81.5m away from the bridge deck. In order to pour the concrete of the beam 2 , the supports 3 of the beam 2 need to be preloaded.

[0044] In order to preload the bracket 3 of the beam 2 simply, quickly and effectively, the method of the present invention is used to preload the bracket 3, and the construction is carried out according to the following steps:

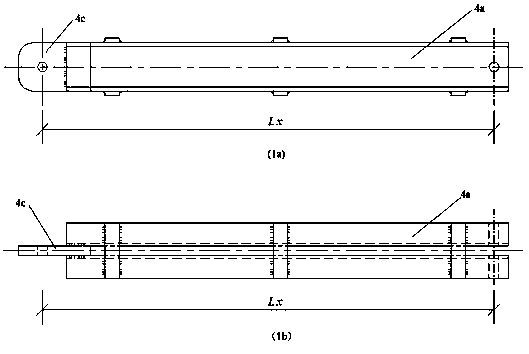

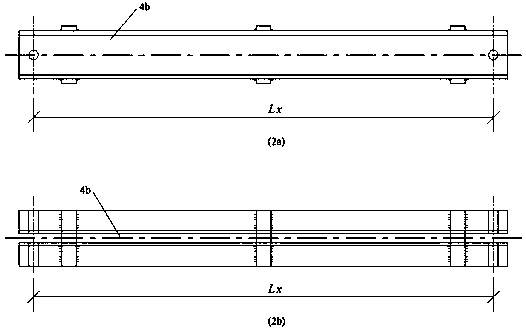

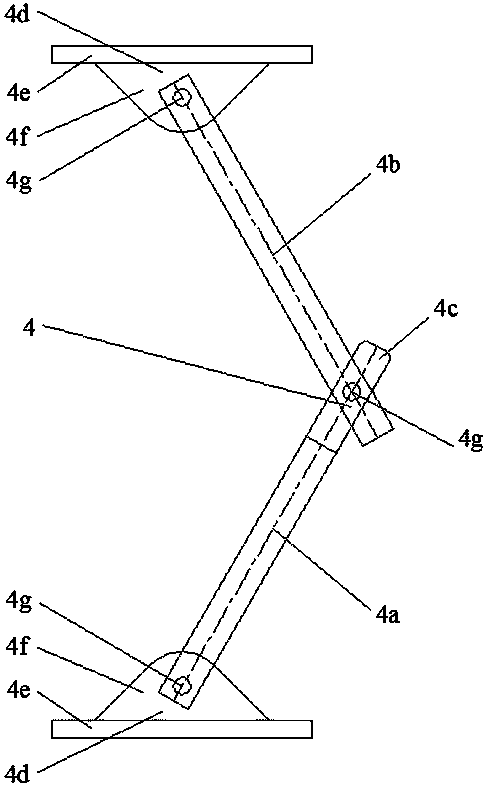

[0045] S1 makes the hinged precompression force transmission structure 4, which is composed of hinged diagonal braces A4a, hinged diagonal braces B4b, and force transmission supports 4d connected by steel pins 4g. Specifically, the hinged brace A4a is composed of two section steels and the male head 4c. There is a gap between the section steels, and the two section steels form a whole through corresponding welding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com