Primer inner explosive filling device

A detonator and charge technology, which is applied to offensive equipment, ammunition, blasting cartridges, etc., can solve problems such as explosion accidents, operator personal safety hazards, and excessive leakage of floating charge, and achieves a simple design structure and realizes man-machine isolation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

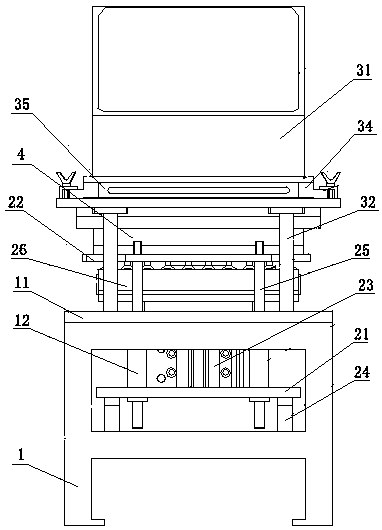

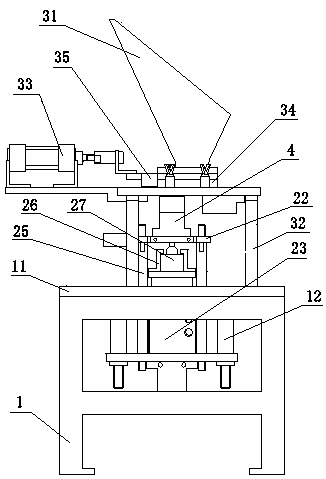

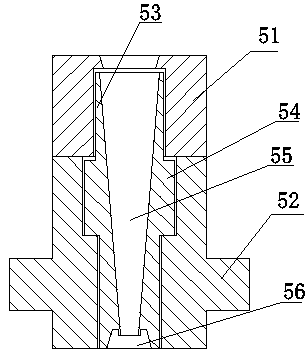

[0023] like figure 1 , figure 2 , image 3 , Figure 4 , a kind of detonator internal explosive charging equipment, including frame 1, charging device, connecting device for connecting charge, drug delivery device,

[0024] The charge device comprises a cylinder connecting plate 21, a connecting plate 22 of the drug connecting device, a driving cylinder 23, a medicine bottle mold fixing device, a vibrator 24, and the connecting plate 22 of the connecting device connecting the drug and the connecting plate 21 of the cylinder pass through a matrix of four The root connecting column 25 is connected as one, and the driving cylinder 23 is fixedly connected to the middle part of the upper side of the cylinder connecting plate 21. The piston of the driving cylinder 23 is fixedly connected to the medicine bottle mold fixing device. The connecting plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com