Universal electroscope with continuous electricity testing function

An electroscope and general-purpose technology, applied in the field of electroscope, can solve the problem of vicious misoperation of live grounding, etc., and achieve the effect of simple and fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

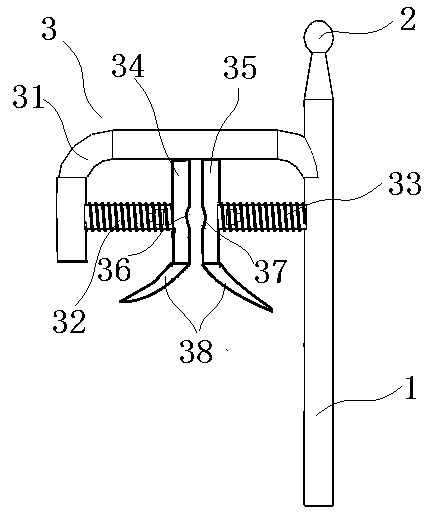

[0015] Such as figure 1 As shown, a general-purpose electroscope with the function of continuous electric inspection includes an electroscope main body and an electric inspection probe, and the electric inspection probe includes an electric inspection pole 1 and an electric examination contact 2; The head 2 is connected, and the other end is electrically connected to the main body of the electroscope; it also includes a continuous electroscope 3, and the continuous electroscope 3 includes a hook 31 of a U-shaped structure, a first elastic clip 32 and a second elastic clip 33, The hook 31 is fixed on the electroscope pole 1, and the first elastic clip 32 and the second elastic clip 33 are arranged on the inner side of the hook 31, respectively connected with the two side walls of the hook 31, the first elastic clip 32 and the second elastic The clips 33 are located on the same horizontal line; the conductor to be tested is sandwiched between the first elastic clip 32 and the se...

Embodiment 2

[0021] The structure of this embodiment is the same as that of Embodiment 1. The difference is that the tops of the first block 34 and the second block 35 are against the top of the hook 31, and the bottoms of the first block 34 and the second block 35 are both Arc-shaped guide strips 38 are provided, and two arc-shaped guide strips 38 form a trumpet-shaped structure. The tops of the first block 34 and the second block 35 are all in contact with the top of the hook 31, so that when the conductor is clamped between the two blocks, the upper ends of the two blocks are blocked by the hook 31, and the conductor It cannot slide out from the top of the two blocks, and when pulled by an external force, the entire electroscope will not fall; the other ends of the first block 34 and the second block 35 are provided with arc-shaped guide strips 38, which is convenient for the conductor to be clamped between the two clamping blocks to play a guiding role; the two arc-shaped guide strips ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com