Separation apparatus of waste magnetic construction material

A separation device and building material technology, applied in magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of automatic collection of materials, easy to generate danger, etc., and achieve the effect of convenient absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

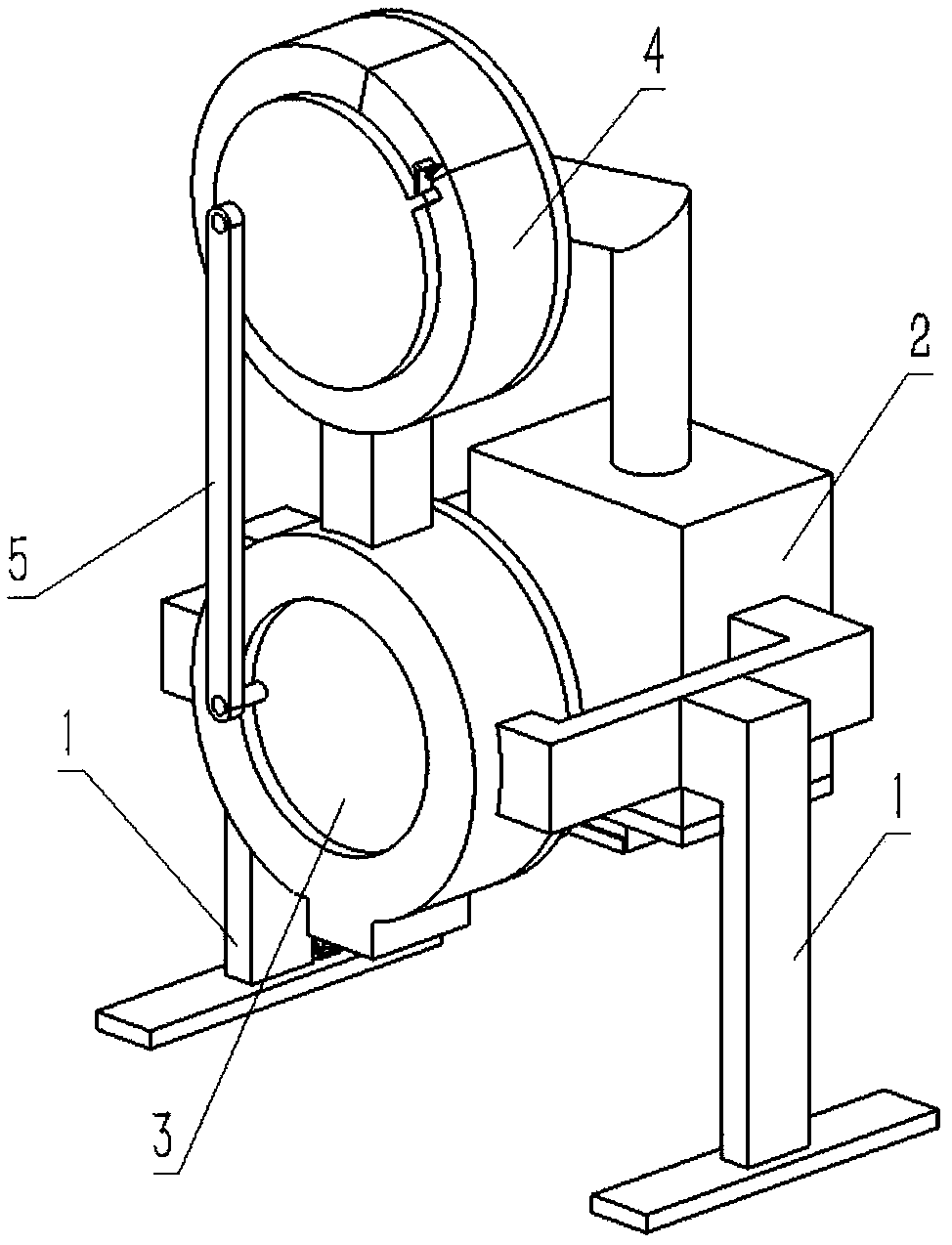

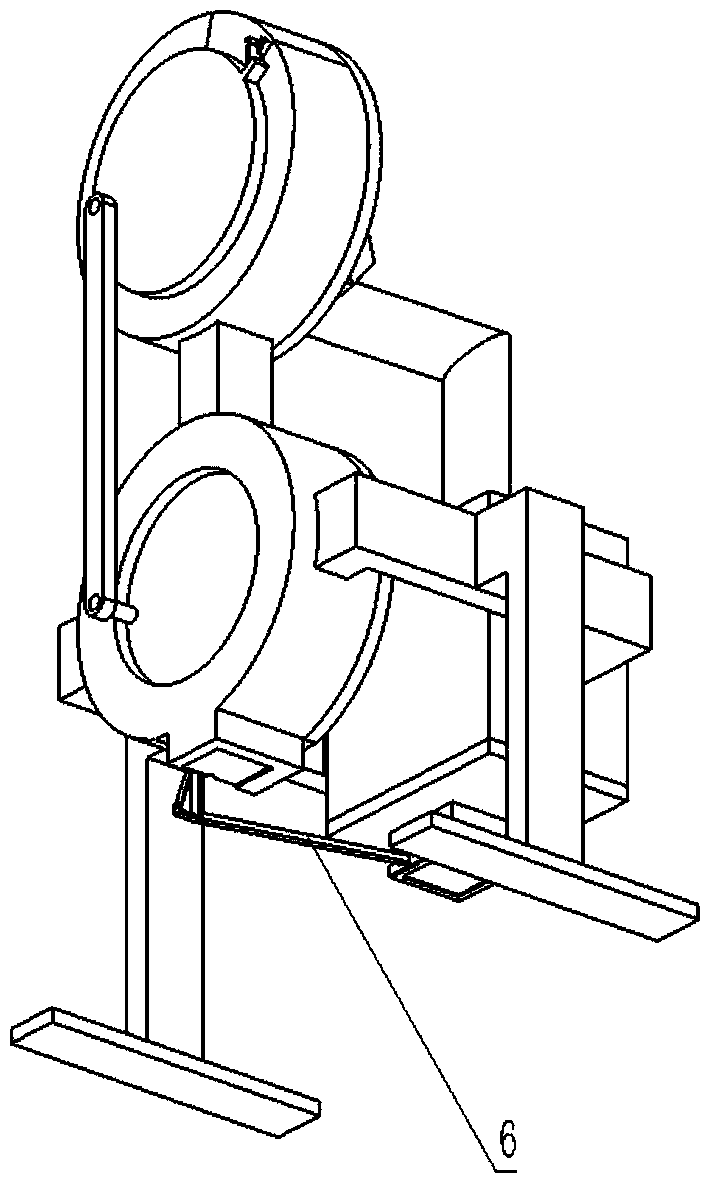

[0042] Combine below Figure 1-23 Describe this embodiment, a separation device for waste magnetic building materials, including two bottom frames 1, a magnetic discharge device 2, a non-magnetic material discharge device 3, a separation device 4, a connecting rod 5 and a lower connecting rod 6, The front and rear ends of the two chassis 1 are fixedly connected to the front and rear ends of the separation device 4 and the non-magnetic material discharge device 3, the separation device 4 is fixedly connected to the upper end of the non-magnetic material discharge device 3, and the non-magnetic The material discharging device 3 communicates with the separating device 4 , the connecting rod 5 is connected between the separating device 4 and the connecting rod 5 , and the lower connecting rod 6 is connected between the magnetic discharging device 2 and the non-magnetic material discharging device 3 .

specific Embodiment approach 2

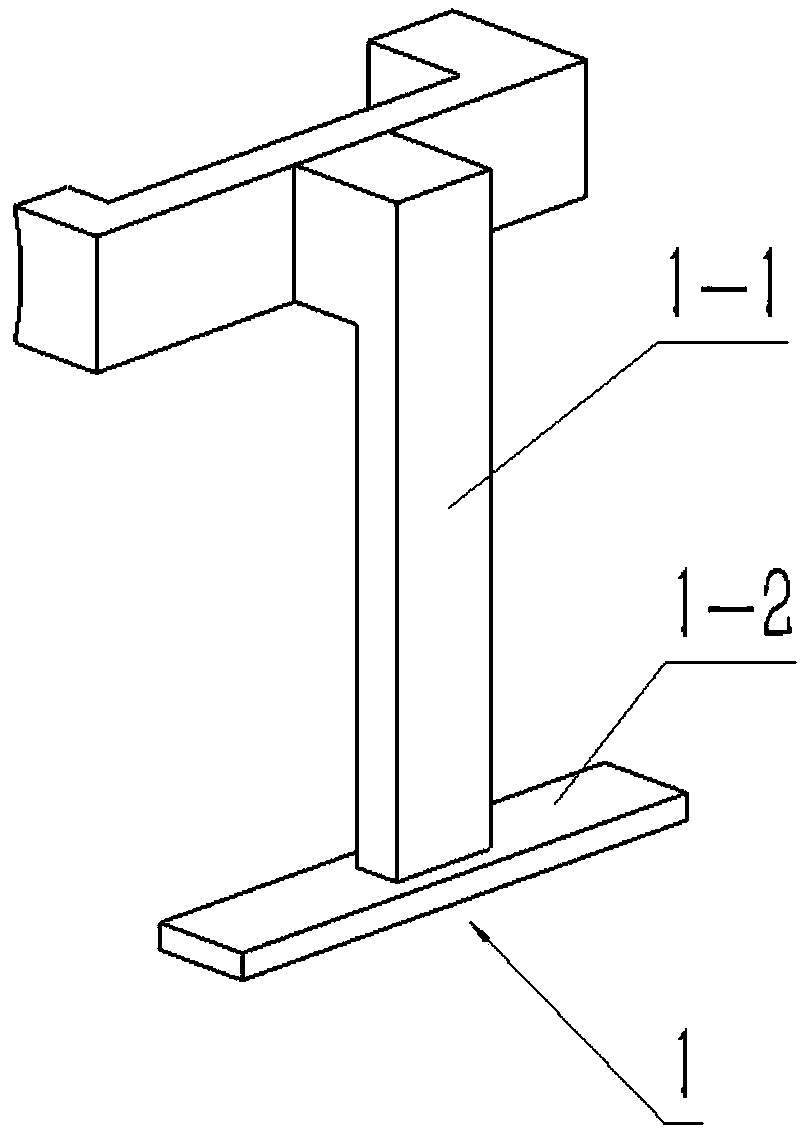

[0043] Combine below Figure 1-23 This embodiment will be described, and this embodiment will further describe Embodiment 1. The chassis 1 includes a support rod 1-1 and a bottom plate 1-2, and the bottom plate 1-2 is fixedly connected to the lower end of the support rod 1-1.

specific Embodiment approach 3

[0044] Combine below Figure 1-23 Describe this embodiment, this embodiment will further explain the second embodiment, the magnetic discharge device 2 includes a magnetic discharge outer frame 2-1, a connecting pipe 2-2, a lower terminal 2-3, a magnetic closing plate 2- 4. The chute 2-5 and the end plate 2-6, the inner end of the magnetic discharge outer frame 2-1 is hollowed out, the connecting pipe 2-2 is fixedly connected to the upper end of the magnetic discharge outer frame 2-1, and the magnetic discharge The outer frame 2-1 communicates with the connecting pipe 2-2, the lower terminal 2-3 is fixedly connected to the lower end of the magnetic discharge outer frame 2-1, the chute 2-5 is arranged at the lower end of the lower terminal 2-3, and the magnetic closing plate 2 -4 is slidingly connected in the magnetic closing plate 2-4, the end plate 2-6 is fixedly connected to the front end of the magnetic closing plate 2-4, and the rear ends of the two struts 1-1 are respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com