Cement stirring machine and feeding and discharging method thereof

A cement mixer, feeding and discharging technology, applied in cement mixing devices, chemical instruments and methods, unloading devices, etc., can solve the problems of inconvenient insertion and removal of test materials, inability to test cement concrete, and incomplete mixing, etc. Save the cost of test equipment, avoid efficiency and safety problems, and achieve complete discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is described in further detail below in conjunction with accompanying drawing:

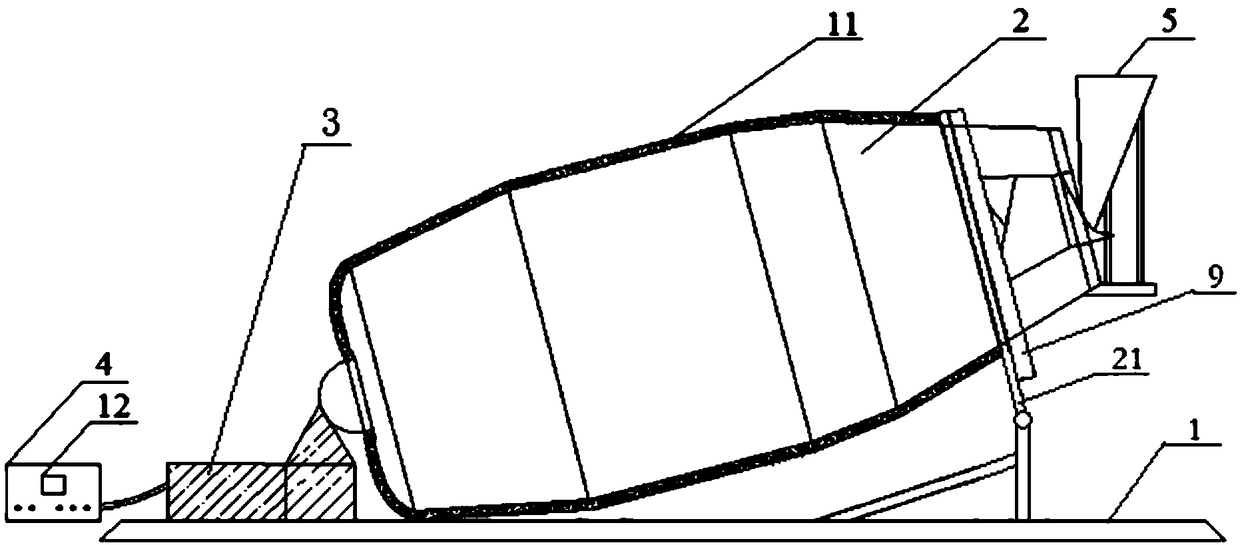

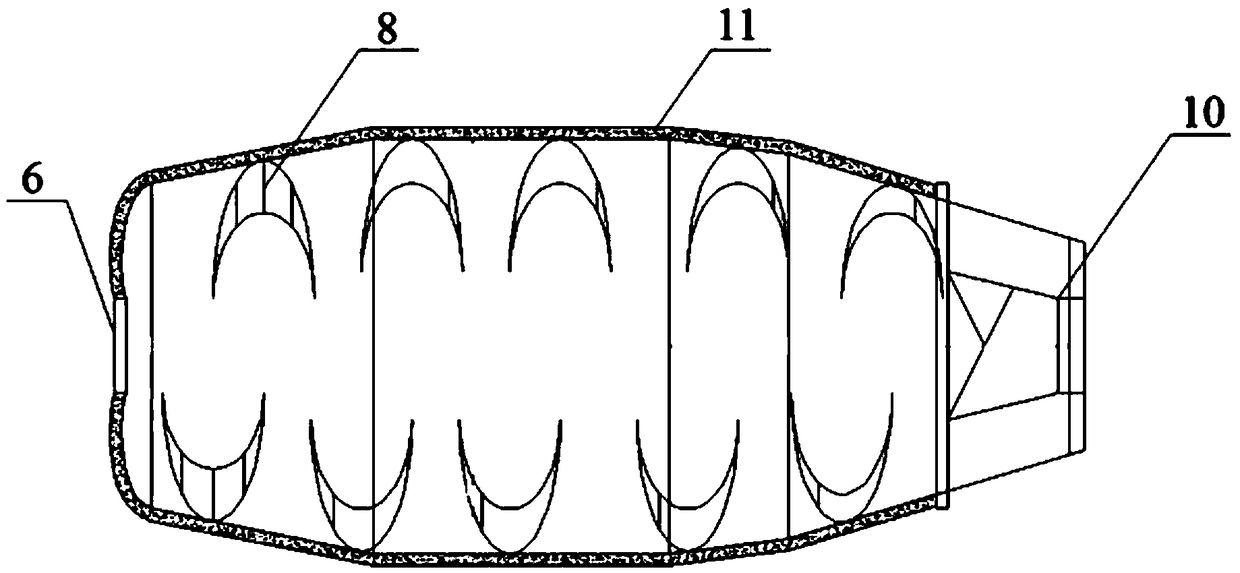

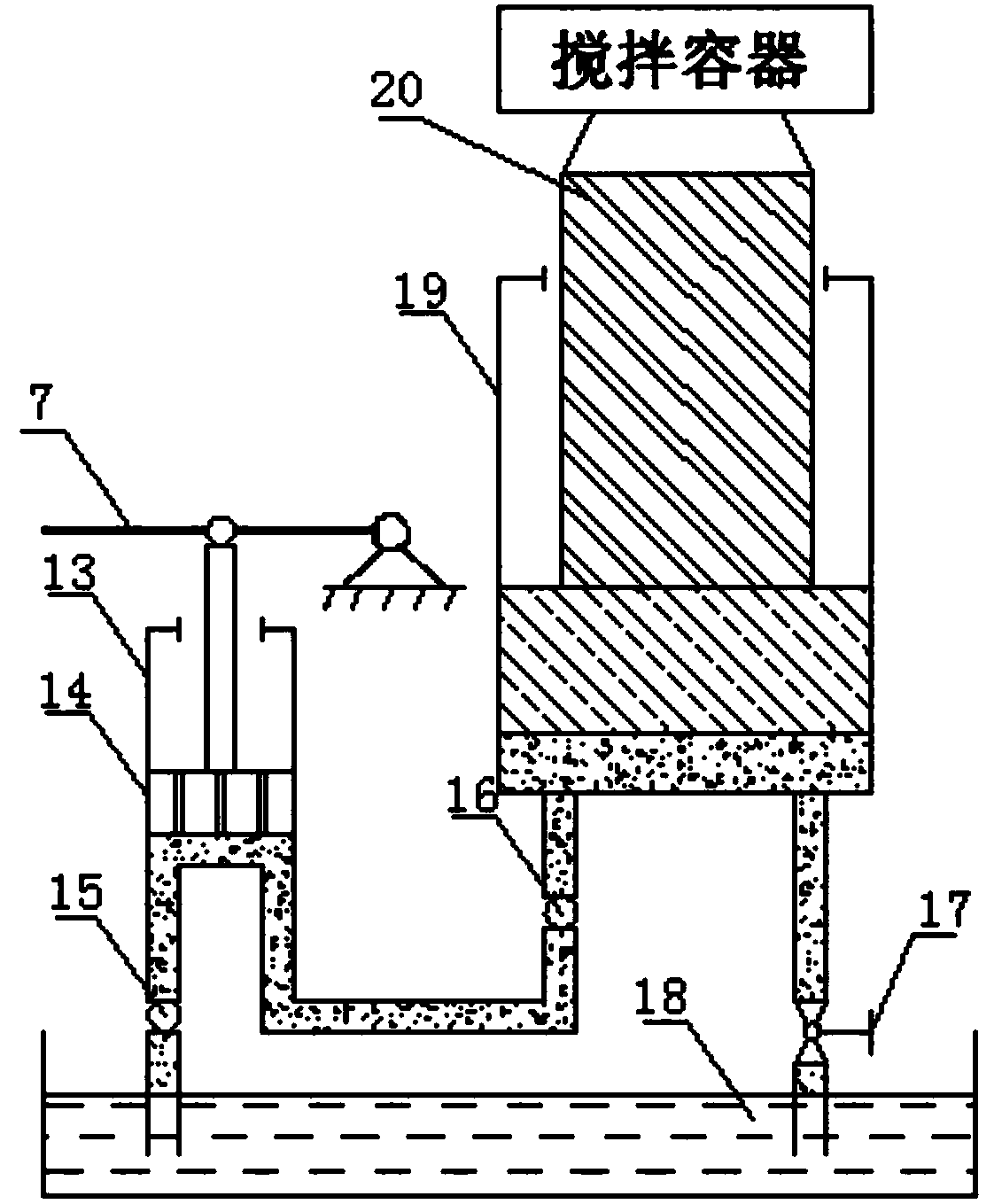

[0036] Such as figure 1 As shown, the present invention is a special instrument and equipment for cement physical performance inspection, which is composed of a stirring frame 1, a stirring container 2, a hydraulic transmission device 3, a control device 4, a feeding device 5, a driving device 9 and a support frame 21; the support frame 21 Fixed on the stirring frame 1, located near the front end of the stirring container 2, used to support the front end of the stirring container 2 to a certain height; the hydraulic transmission device 3 is fixed on the stirring frame 1, located at the rear end of the stirring container 2; the stirring container 2 is fixed On the support frame 21, the interior of the stirring container 2 is hollow, and the front end face is provided with an inlet and outlet 10; the feeding device 5 is hinged and fixed on the stirring container 2 throug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com