Down collecting device

A collection device and down technology, applied in the field of garment processing, can solve the problems affecting the collection effect of down, affecting the normal operation of a vibrating screen, etc., and achieve the effect of helping the collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following is further described in detail through specific implementation methods:

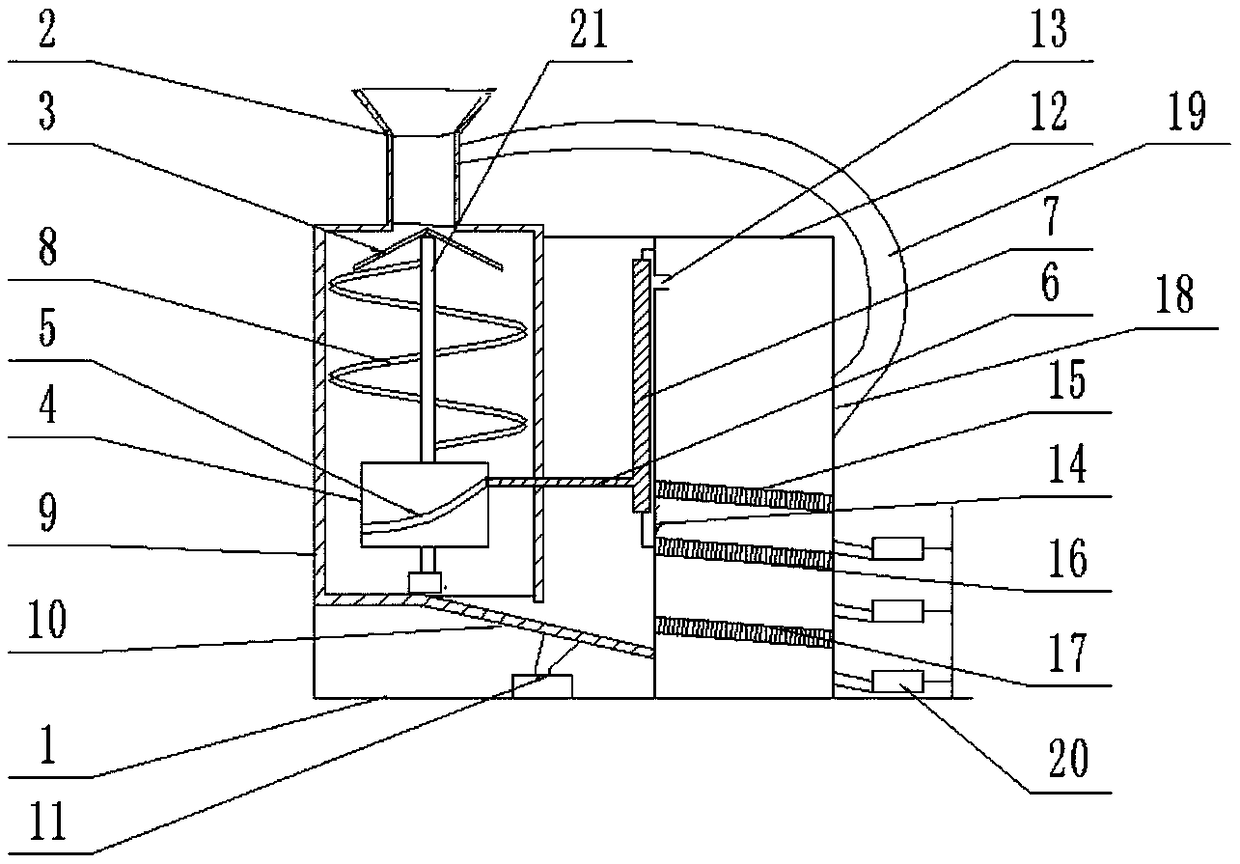

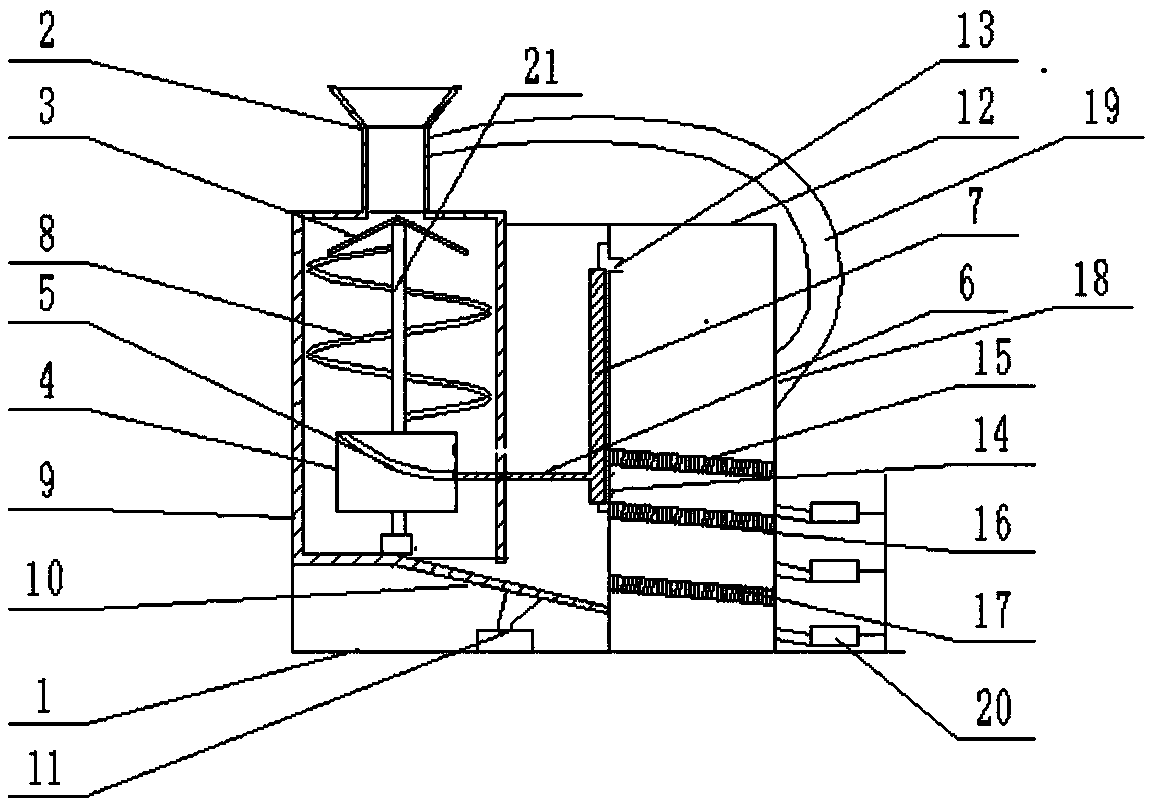

[0019] The reference signs in the drawings of the description include: collection box 1, conveying cylinder 2, conical plate 3, cylindrical cam 4, curved groove 5, transmission rod 6, vertical plate 7, spiral blade 8, cylinder 9, guide plate 10 , hot air blower 11, rectangular screen box 12, conveying hole 13, air inlet 14, first vibrating screen 15, second vibrating screen 16, third vibrating screen 17, recovery port 18, connecting pipe 19, collecting tank 20, rotating shaft twenty one.

[0020] The embodiment is basically as attached figure 1 and 2 Shown:

[0021] The orientation words such as "left and right" described in this embodiment are only appended to this embodiment. figure 1 and figure 2 , a collection device for collecting down, such as figure 1 As shown, a collection box 1 is included, and a delivery cylinder 2 is installed on the top of the collection box 1. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com