Washing machine, cleaning brush, washing machine cleaning method and medium

A washing machine and cleaning brush technology, applied in the field of washing machines, can solve problems such as inconvenient cleaning, and achieve the effect of simple and fast cleaning, simple and fast cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

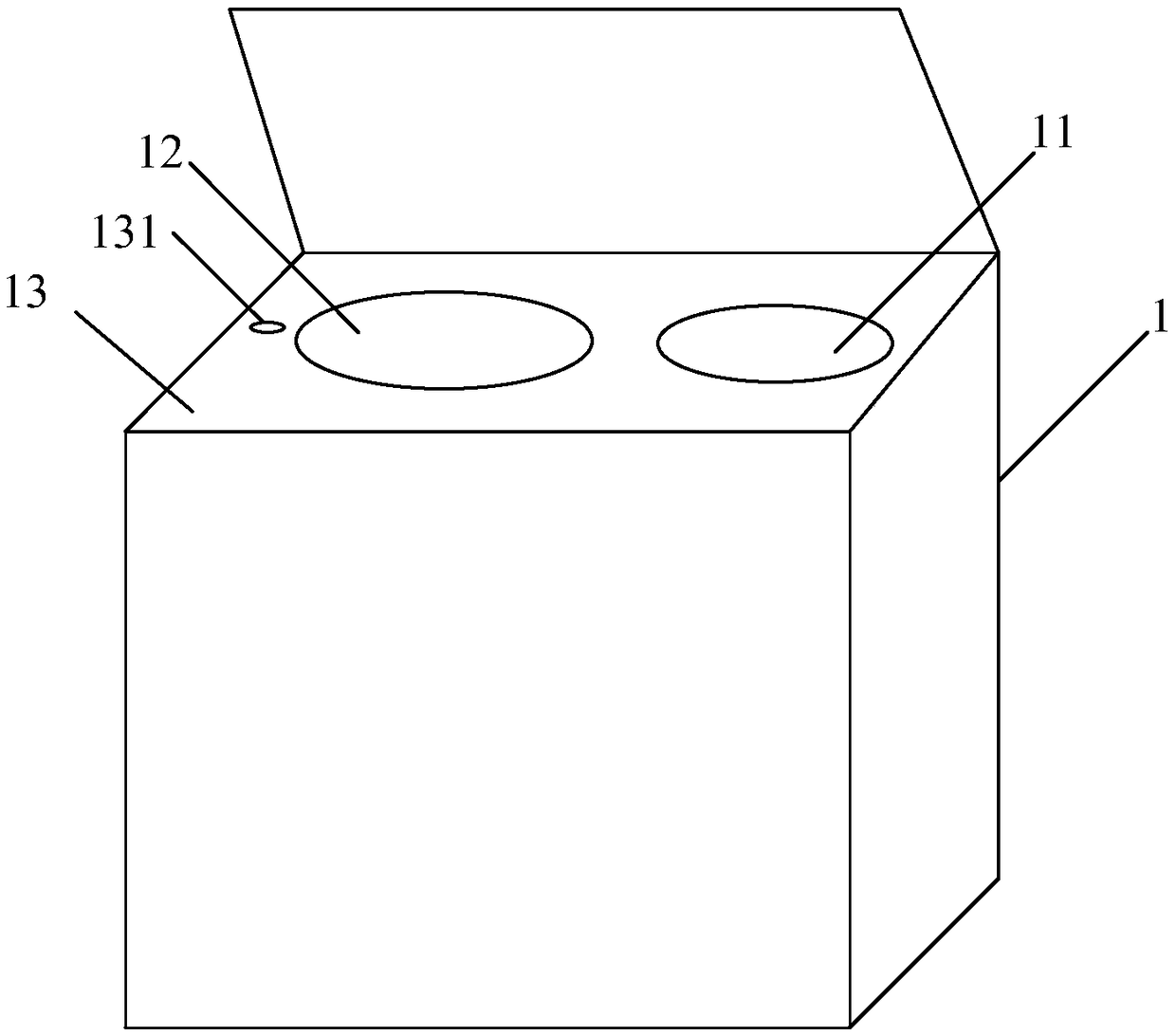

[0034] figure 1 It is a schematic diagram of the washing machine provided by Embodiment 1 of the present invention. The washing machine includes: a body 1, a cylinder assembly 12 and a safety wall 13; the cylinder assembly is arranged in the body 1, including an inner cylinder and an outer cylinder that are sheathed together and open in the same direction; the safety wall 13 is arranged in front of the opening of the cylinder assembly , and a cleaning port 131 is opened, and the cleaning port 131 faces the interval cavity between the inner cylinder and the outer cylinder.

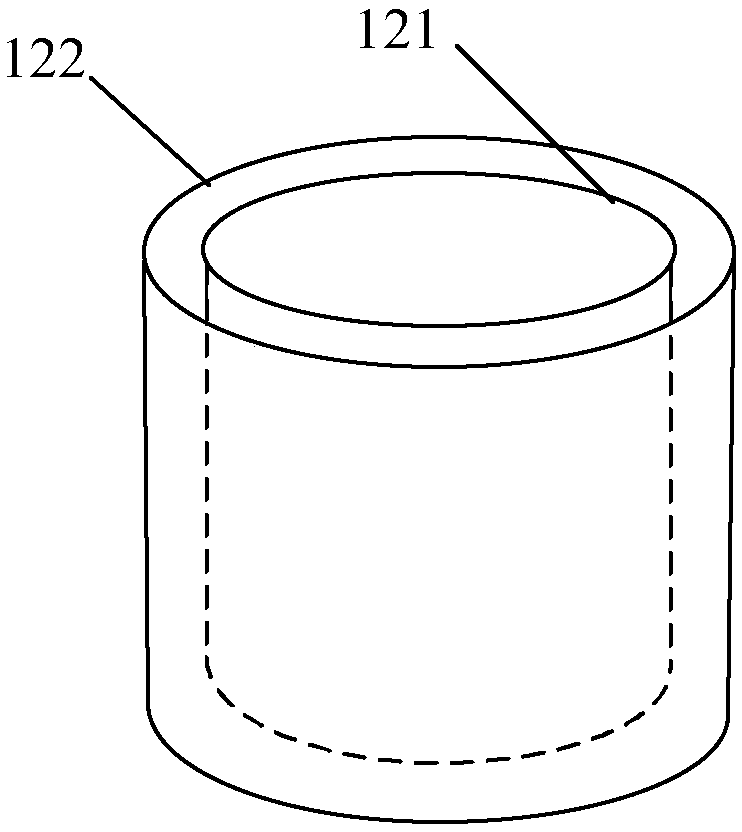

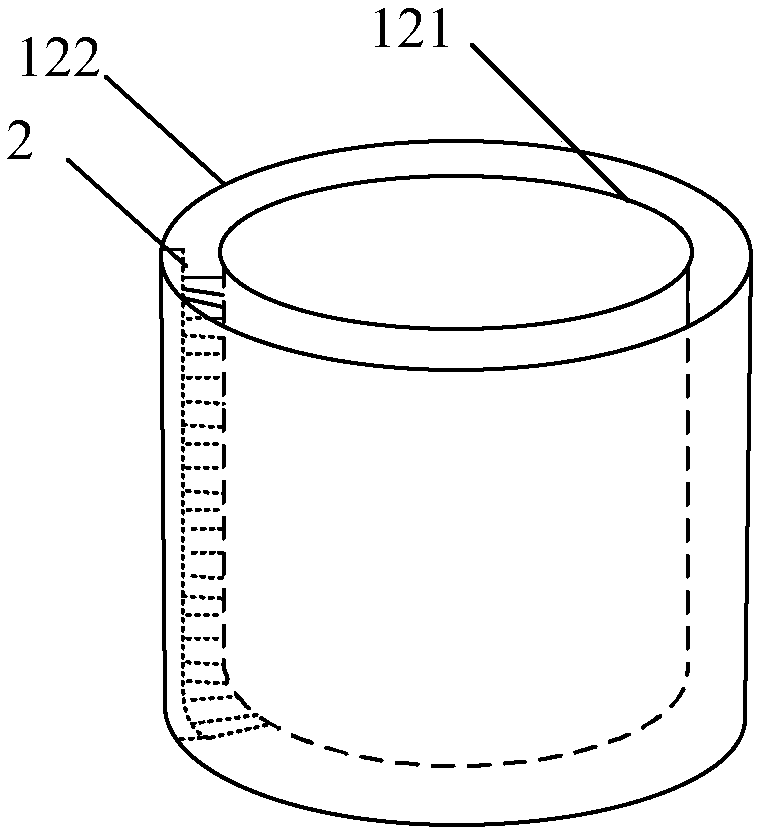

[0035] Washing machines generally include a tub assembly 12, such as figure 2 As shown, the cylinder assembly 12 includes an inner cylinder 121 and an outer cylinder 122 that are sheathed together and open in the same direction. There is a gap between the inner cylinder 121 and the outer cylinder 122 . As the use time of the washing machine increases, there will be more and more dirt on the walls of the ...

Embodiment 2

[0041] Figure 5 It is a structural schematic diagram of the cleaning brush provided by Embodiment 2 of the present invention. The cleaning brush 2 is used to clean the outer wall of the inner cylinder and / or the inner wall of the outer cylinder of the washing machine cylinder assembly described in the foregoing embodiments. The cleaning brush 2 includes: a brush head 21, and at least bristles 22 arranged on one side of the brush head 21; The total thickness of the head 21 and the bristles 22 is greater than the interval between the inner cylinder and the outer cylinder, and the thickness of the brush head 21 is smaller than the interval between the inner cylinder and the outer cylinder; the length of the brush head is less than the outer wall of the inner cylinder and / or the inner side of the outer cylinder The side length of the total slope of the wall.

[0042] Wherein, the brush head 21 is made of non-rigid material, so that the cleaning brush can extend into the gap betw...

Embodiment 3

[0048] Image 6 It is a flow chart of the washing machine cleaning method provided by Embodiment 3 of the present invention. The technical solution of this embodiment is suitable for cleaning the washing machine described in the foregoing embodiments. Such as figure 1 As shown, the washing machine includes a body 1, a cylinder assembly 12 and a safety wall 13. The cylinder assembly 12 is arranged in the body 1, and includes an inner cylinder and an outer cylinder that are sheathed together and open in the same direction; the safety wall 13 is arranged on the cylinder assembly. The front of the opening 12 is provided with a cleaning port 131, and the cleaning port 131 faces the interval cavity between the inner cylinder and the outer cylinder. The washing machine also includes a control mechanism and a rotation mechanism, and the rotation mechanism rotates the tub assembly 12 under the control of the control mechanism. The method specifically includes the following steps:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com