Soft cleaning equipment for textile fabrics

A technology for textile cloth and cleaning equipment, which is applied in the direction of processing textile material equipment configuration, textile material processing, and partial processing of textile materials, etc., and can solve problems such as complex structure, inability to clean, and impossibility of cloth vibration cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

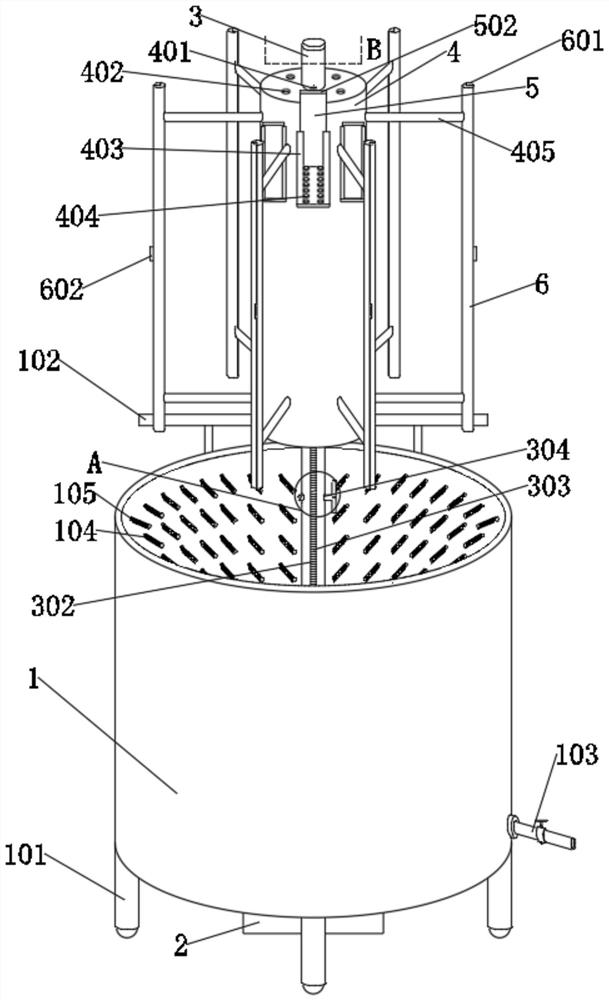

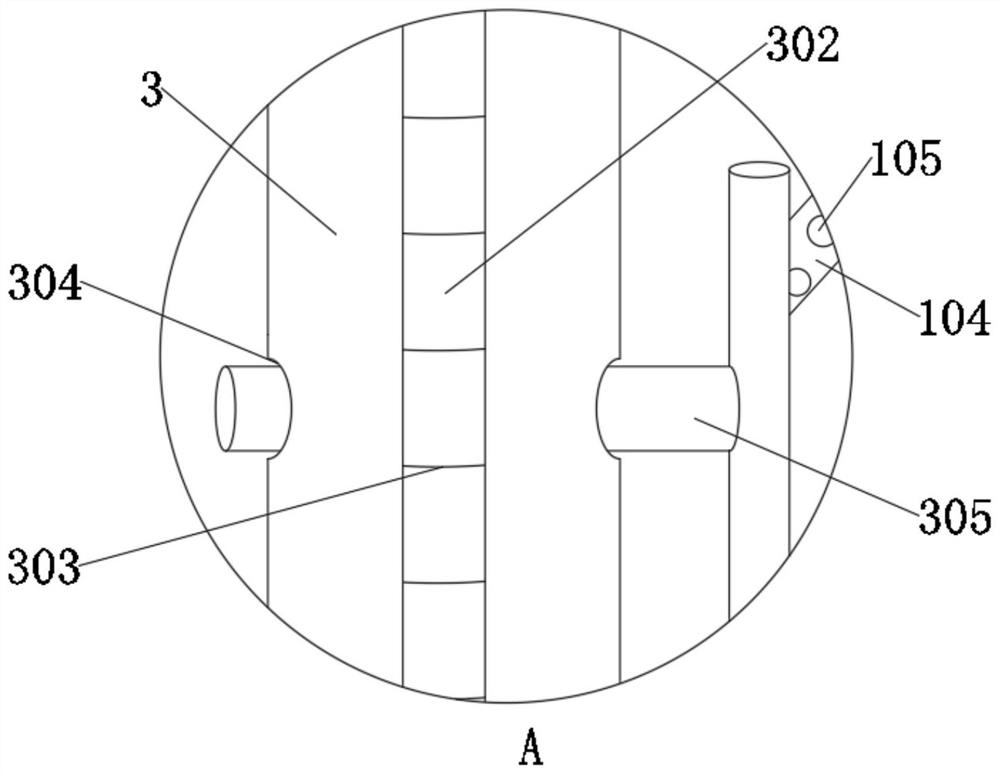

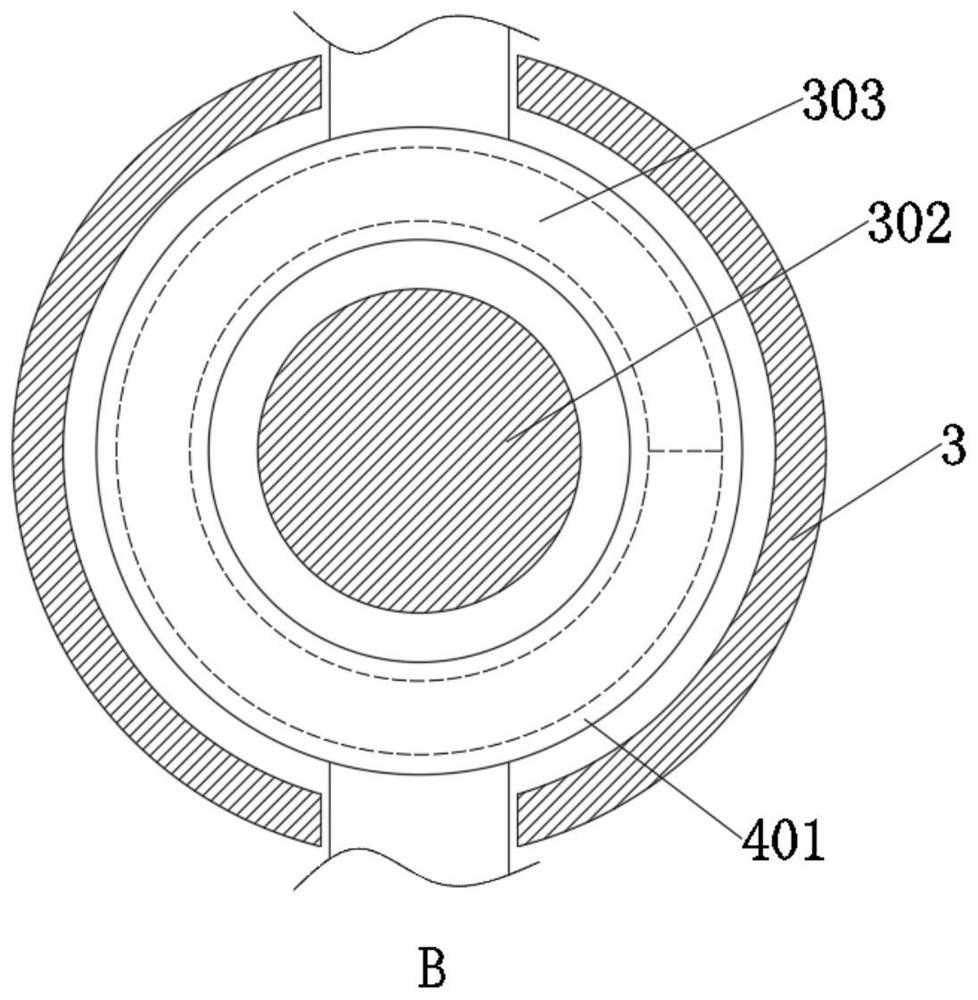

[0031] as attached figure 1 to attach Figure 8 Shown:

[0032] The invention provides a flexible cleaning equipment for textile fabrics, which includes: a main body 1, a universal wheel 101, a push rod 102, a discharge port 103, a cleaning column 104, a cleaning point 105, a flow guide 106, a motor cover 2, a transmission Shaft 201, stirring fan 202, supporting column 3, inner column 302, supporting spring 303, limiting hole 304, limiting member 305, moving member 4, receiving ring 401, adding hole 402, fixing member 403, discharge hole 404, Connecting column 405, sealing plate 5, sealing member 501, pulling plate 502, fixing column 6, fitting member 601, moving member 602, clamping member 603 and fixing spring 604; the bottom edge of main body 1 is installed by welding Universal wheel 101, and the top of the back of the main body 1 is equipped with a push rod 102 through the support column, and the side of the main body 1 is provided with a discharge port 103, and the midd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com