Auxiliary device and differential pressure sensor assembly

A technology of sensor components and auxiliary devices, applied in the direction of measuring devices, pressure difference measurement between multiple valves, instruments, etc., can solve the problems of shortened life, easy entry of dust, unstable test values, etc., to improve stability, The effect of avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with embodiment, but is not limited to the content on the description.

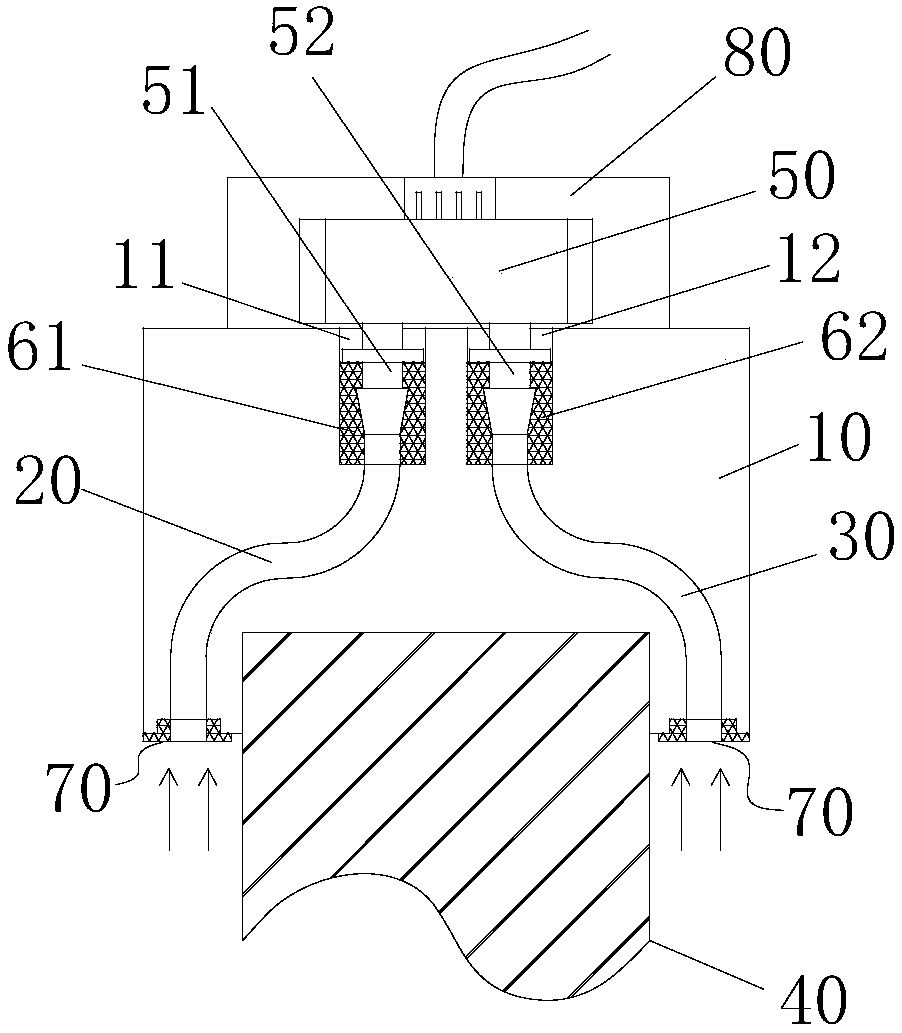

[0029] Such as figure 1 As shown, the present invention discloses an auxiliary device, including a housing 10, a first flow channel 20 and a second flow channel 30 are arranged in the housing 10, and the entrance of the first flow channel 20 and the entrance of the second flow channel 30 are respectively located at At different positions of the detected object 40 , the outlet of the first flow channel 20 and the outlet of the second flow channel 30 are all in communication with the differential pressure sensor 50 . According to the present invention, the first flow channel 20 and the second flow channel 30 are arranged in the housing 10, and the entrance of the first flow channel 20 and the entrance of the second flow channel 30 are respectively located at different positions of the detected object 40, which are detected during de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com