A design method of submarine cable conductor with circular monofilament compact structure

A design method and conductor technology, applied in conductors, submarine cables, non-insulated conductors, etc., can solve the problems of no conductors, imperfect design methods for large-section submarine cable conductors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

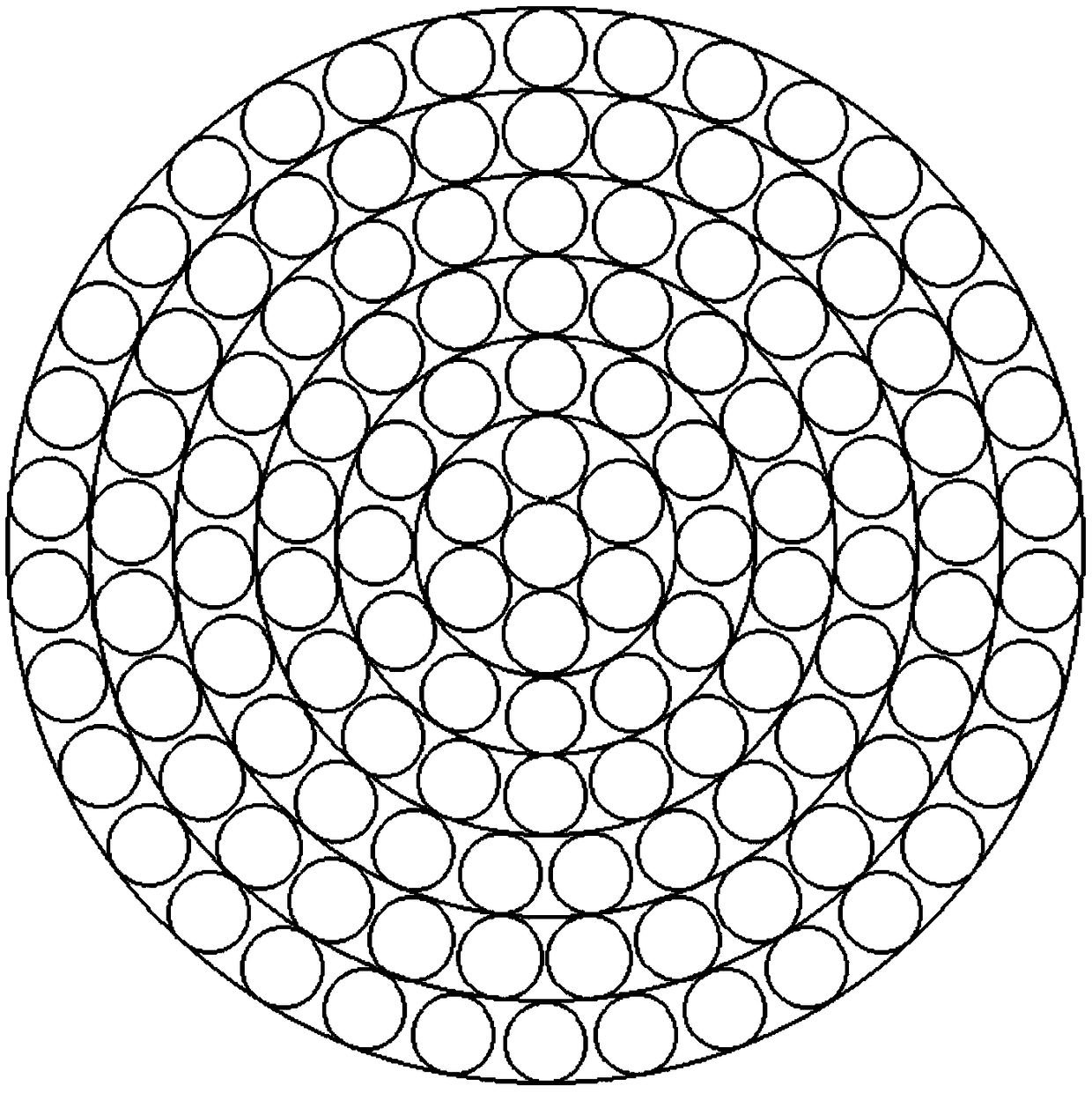

Image

Examples

Embodiment 1

[0041] The section is S=2000mm 2 The design method of the conductor, the specific steps include:

[0042] 1) Determine the resistance: determine the resistance R of the designed submarine cable conductor cu , in this example, R cu = 0.0090Ω / km.

[0043] 2) Calculate the outer diameter of the conductor D A and monofilament diameter d: the resistance R of the submarine cable conductor confirmed in step 1) cu Substitute into the calculation formula (1) to calculate the outer diameter of the conductor D A and the monofilament diameter d,

[0044]

[0045] where S is the cross-sectional area of the conductor, k 1 is the conductivity coefficient, k 2 is the stranding coefficient, ρ cu is the resistivity of the copper conductor, R cu is the resistance, η is the conductor filling factor, μ is the compression factor, k 3 Is the coefficient of whether it is cabled or not, n is the total number of single wires, by querying the conductor resistance requirements specified in...

Embodiment 2

[0080] The section is S=1800mm 2 The design method of the conductor, the specific steps include:

[0081] 1) Determine the resistance: determine the resistance R of the designed submarine cable conductor cu , in this example, R cu = 0.0101Ω / km.

[0082] 2) Calculate the outer diameter of the conductor D A and monofilament diameter d: the resistance R of the submarine cable conductor confirmed in step 1) cu Substitute into the calculation formula (1) to calculate the outer diameter of the conductor D A and the monofilament diameter d,

[0083]

[0084] where S is the cross-sectional area of the conductor, k 1 is the conductivity coefficient, k 2 is the stranding coefficient, ρ cu is the resistivity of the copper conductor, R cu is the resistance, η is the conductor filling factor, μ is the compression factor, k 3Is the coefficient of whether it is cabled or not, n is the total number of single wires, by querying the conductor resistance requirements specified in ...

Embodiment 3

[0114] The section is S=1600mm 2 The design method of the conductor, the specific steps include:

[0115] 1) Determine the resistance: determine the resistance R of the designed submarine cable conductor cu , in this example, R cu = 0.0113Ω / km.

[0116] 2) Calculate the outer diameter of the conductor D A and monofilament diameter d: the resistance R of the submarine cable conductor confirmed in step 1) cu Substitute into the calculation formula (1) to calculate the outer diameter of the conductor D A and the monofilament diameter d,

[0117]

[0118] where S is the cross-sectional area of the conductor, k 1 is the conductivity coefficient, k 2 is the stranding coefficient, ρ cu is the resistivity of the copper conductor, R cu is the resistance, η is the conductor filling factor, μ is the compression factor, k 3 Is the coefficient of whether it is cabled or not, n is the total number of single wires, by querying the conductor resistance requirements specified in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com