Electric planer

An electric planer and limit groove technology, which is used in the manufacture of flat surface processing machines, wood processing appliances, manufacturing tools, etc., can solve the problems of troublesome installation and replacement, time-consuming and laborious, and achieve a convenient and fast installation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

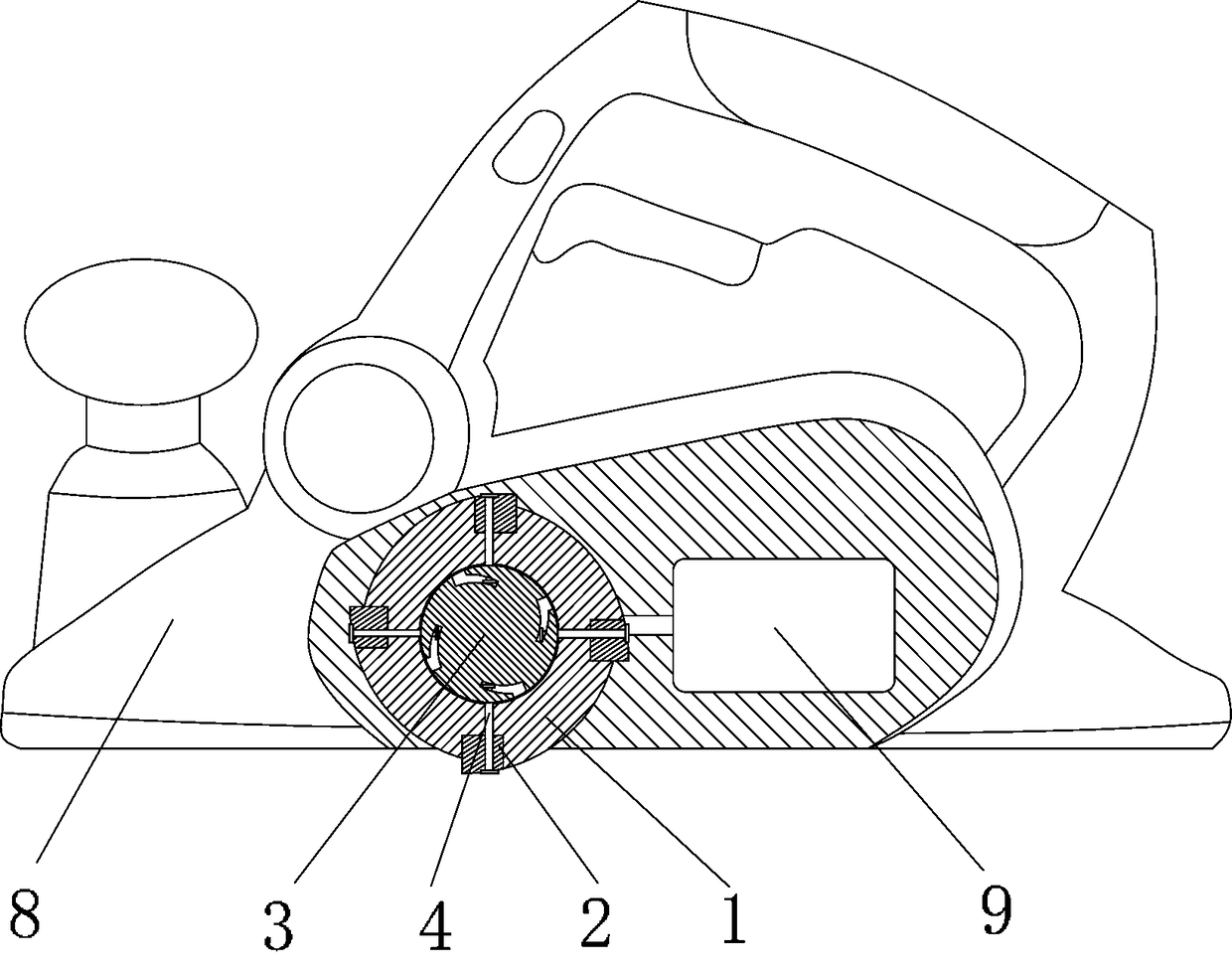

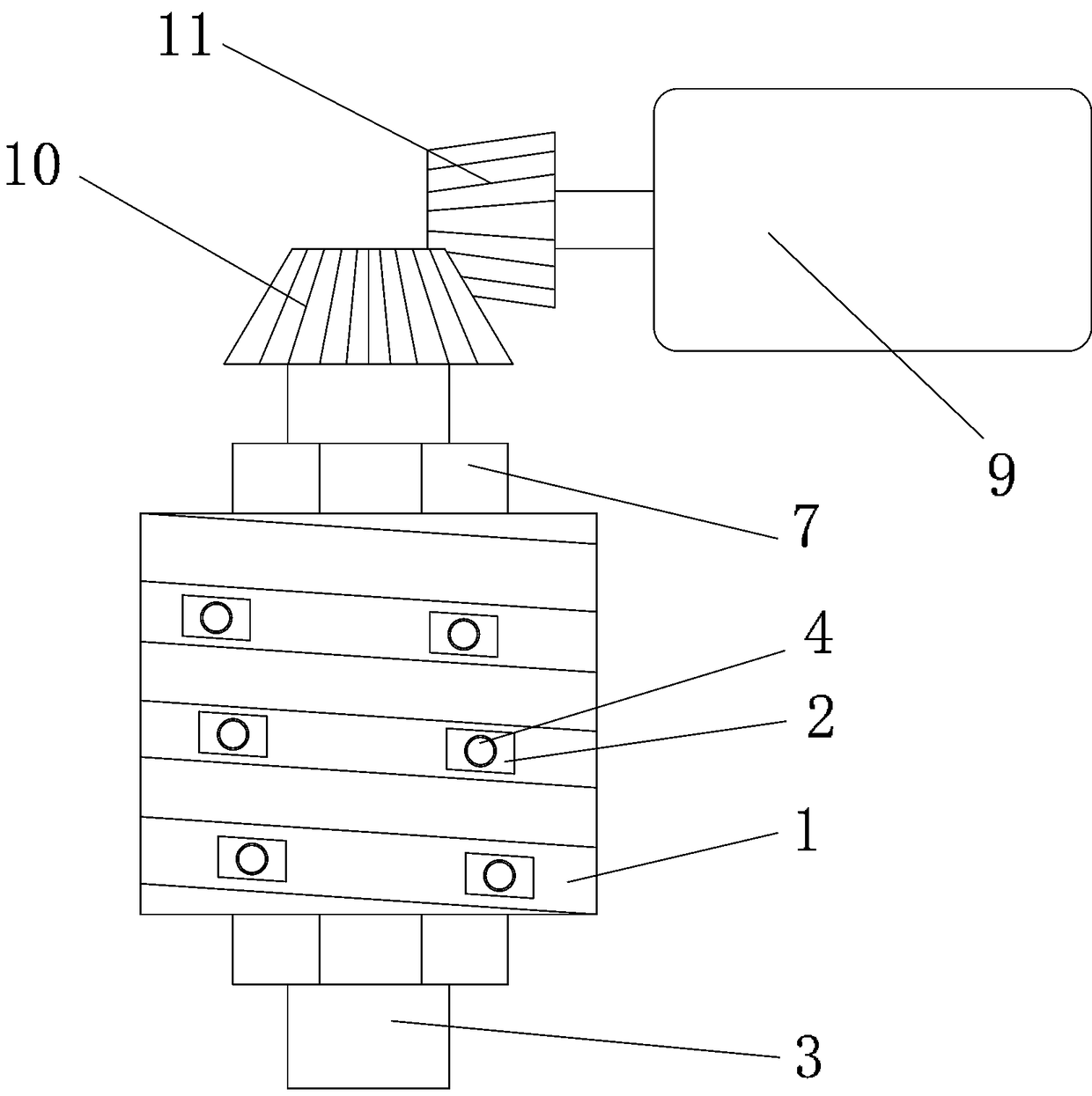

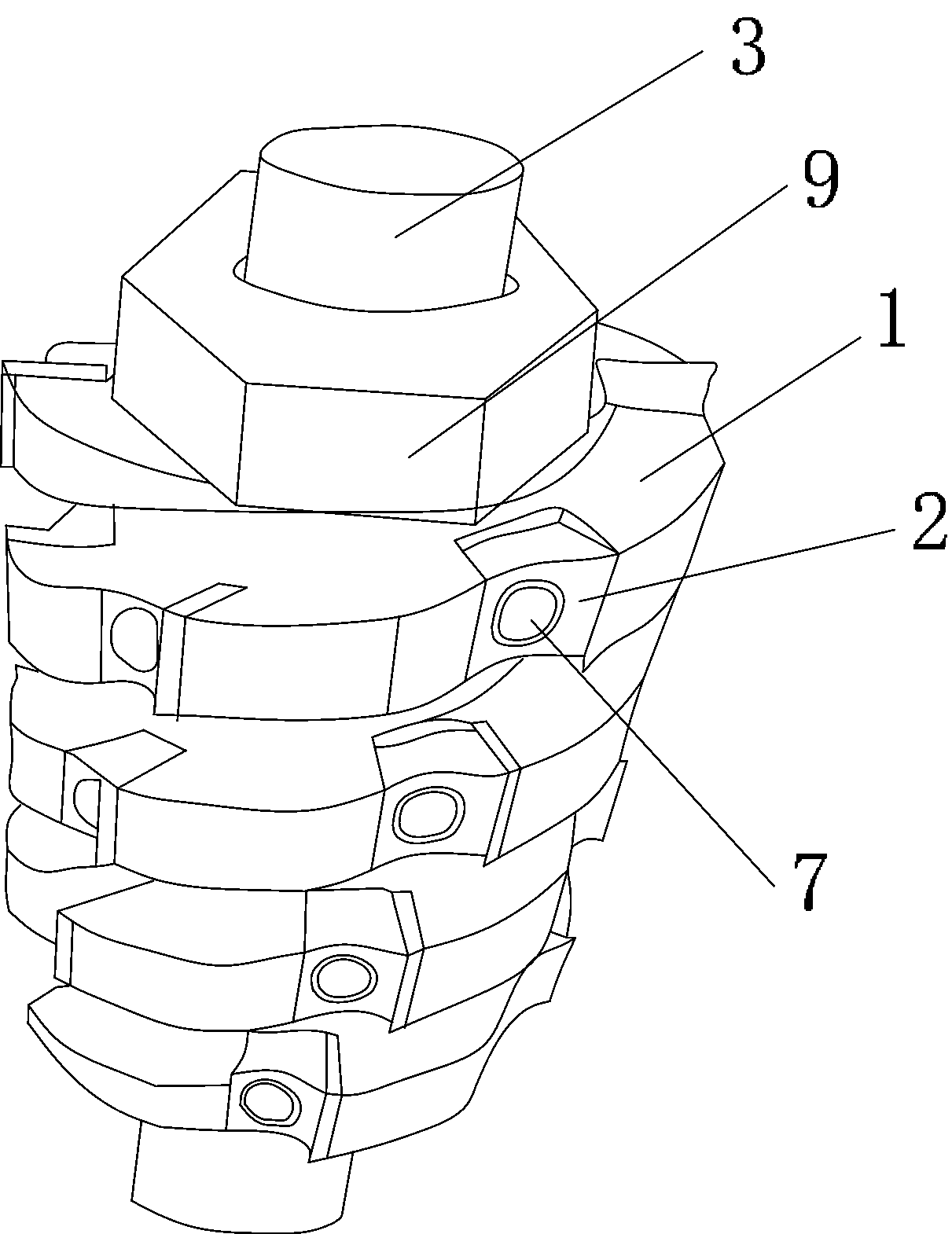

[0023] exist Figure 1-6 Among them, an electric planer includes an electric planer 8, a cutter body 1, a cutter head 2, a rotating shaft 3 and a fixed shaft 4, the rotating shaft 3 is installed in the cutter body 1, and the first connecting shaft is arranged on the rotating shaft 3. Limiting groove 5 and the second limiting groove 6, the number of the first limiting groove 5 and the second limiting groove 6 is 16, the first limiting groove 5 and the second limiting groove 6 spirals are evenly distributed on the rotating shaft 3, and the distance from the notch of the second limiting 6 to the axis of the rotating shaft 3 is greater than the distance from the tail of the second limiting 6 groove to the axis of the rotating shaft 3. The fixed shaft 4 passes through the cutter head 2 and the cutter body 1 and snaps into the first limiting groove 5, and the rotating shaft 3 is rotated to move the fixed shaft 4 from the first limiting groove 5 to the first limiting groove 5. In th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap