Sand layer laying device for producing fiber reinforced plastic composite pipe lining

A laying device and glass fiber reinforced plastic technology, which is applied to surface layering devices, auxiliary forming equipment, ceramic forming machines, etc., can solve the problems of difficult laying, difficult to realize the laying interval of abrasive belts, and inability to realize the interval between abrasive belts, etc. The effect of cleaning and sand laying evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

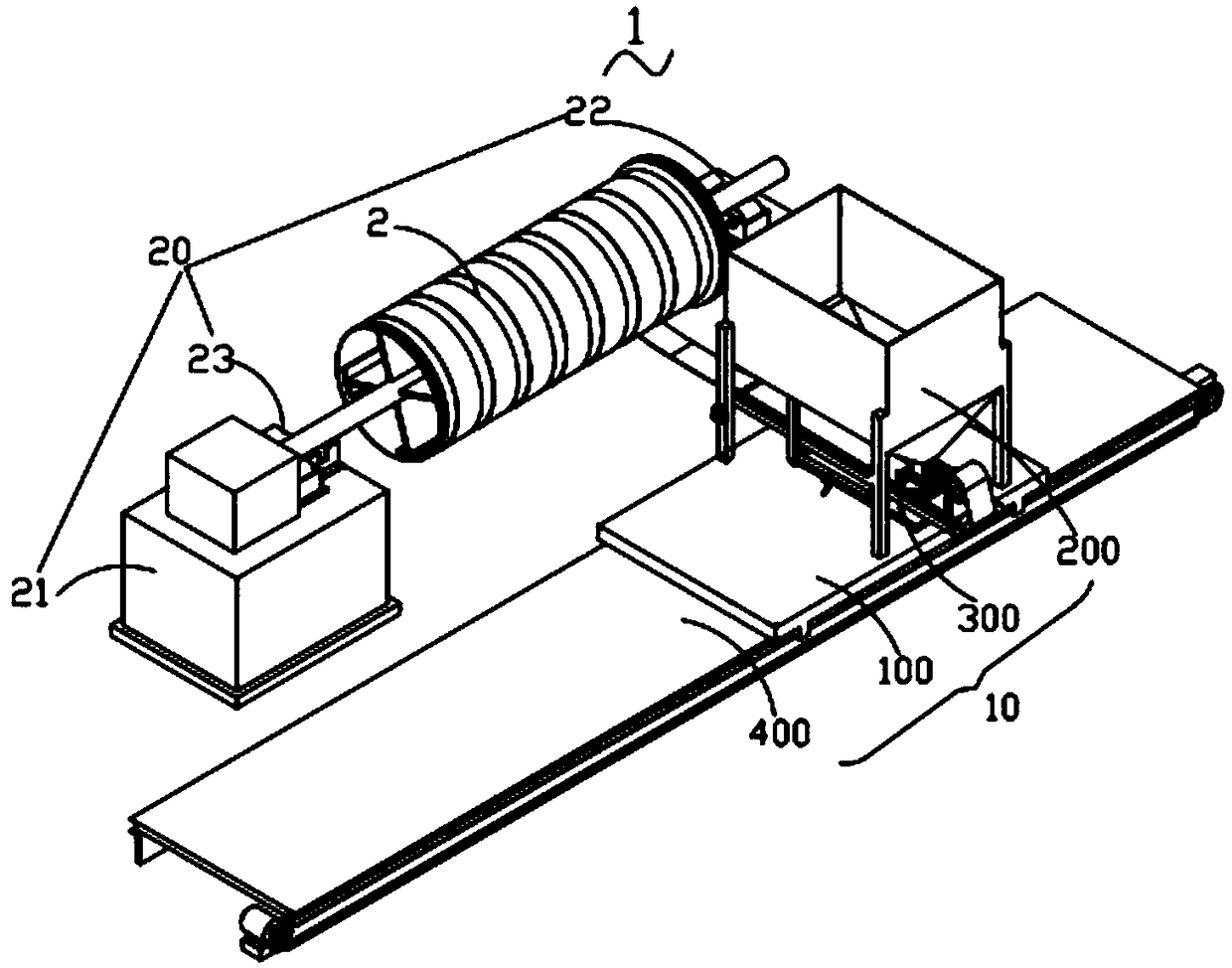

[0030] Please see figure 1 , in one embodiment, a kind of sand laying device 1 for producing reinforced concrete fiberglass composite pipe liner, is used for laying the annular sand belt on the fiberglass lining 2 to be sanded, including fiberglass lining rotation mechanism 20 and sand belt The forming mechanism 10, the FRP lining rotating mechanism 20 is used to realize the axial rotation of the FRP lining 2 to be sanded, and the abrasive belt forming mechanism 10 is arranged in parallel with the FRP lining rotating mechanism 20.

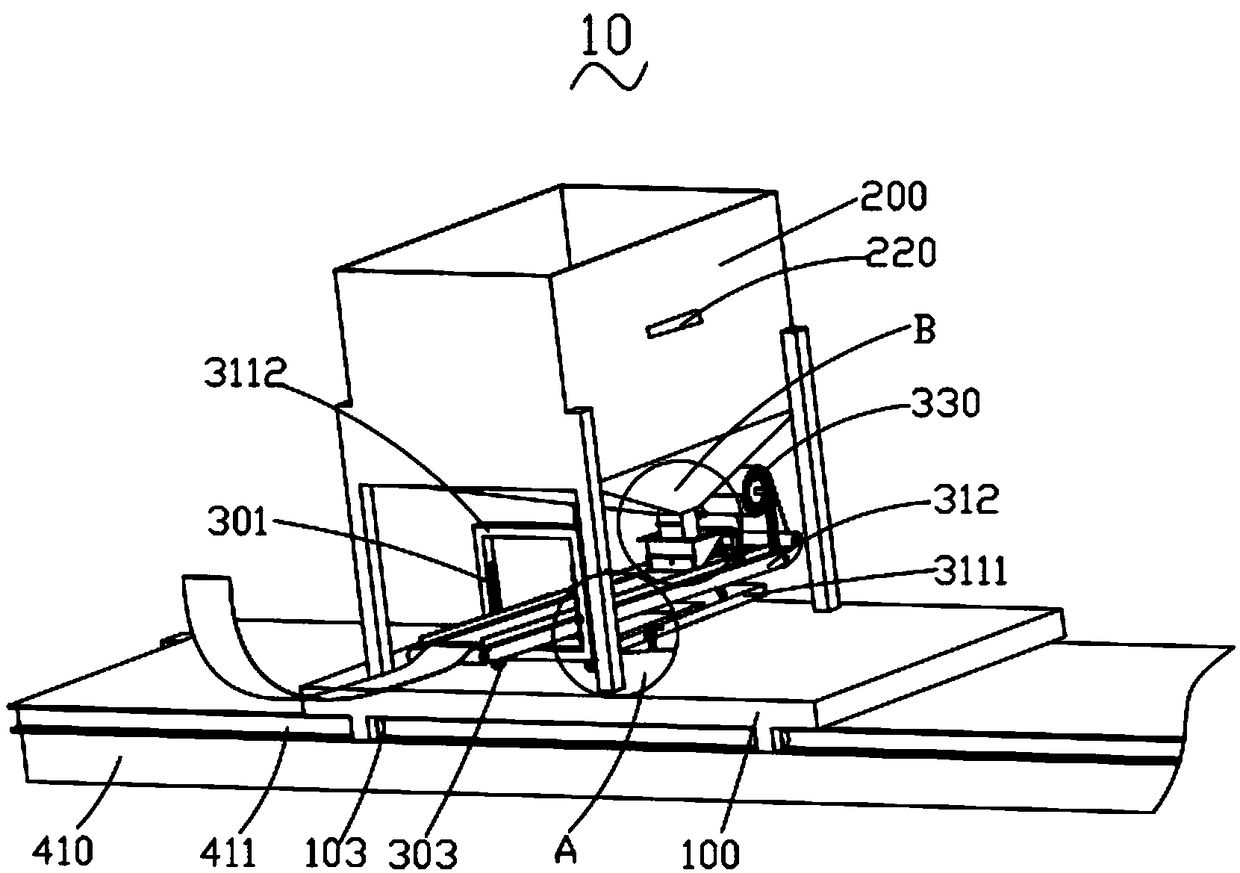

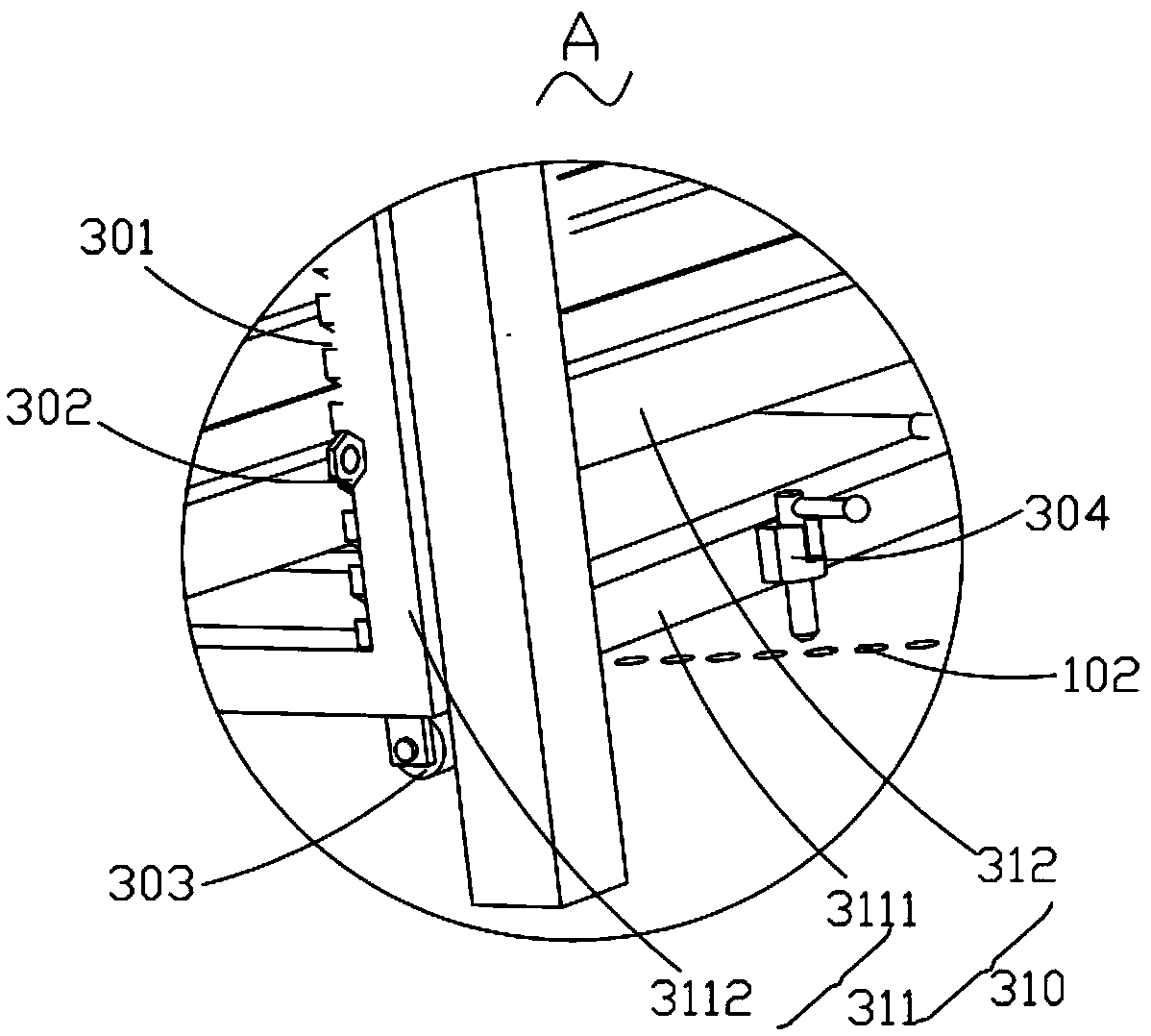

[0031] The abrasive belt forming mechanism 10 includes a bearing platform 100, a sand bucket 200, an abrasive belt laying assembly 300 and an abrasive belt spacing forming assembly 400. An equipment space is formed, and a sand outlet 210 is opened at the bottom of the sand bucket 200, and the sand outlet 210 also has the function of limiting the sand output.

[0032] The abrasive belt laying assembly 300 is installed on the bearing platform 100 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com