Lifting connection mechanism for automobile battery changing station

A technology for battery swapping stations and automobiles, which is applied to lifting frames, lifting devices, vehicle maintenance, etc., can solve the problems of increased design difficulty, poor applicability of charging and swapping stations, flexible adjustment, etc., to save equipment manufacturing costs, high work efficiency, and operation. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

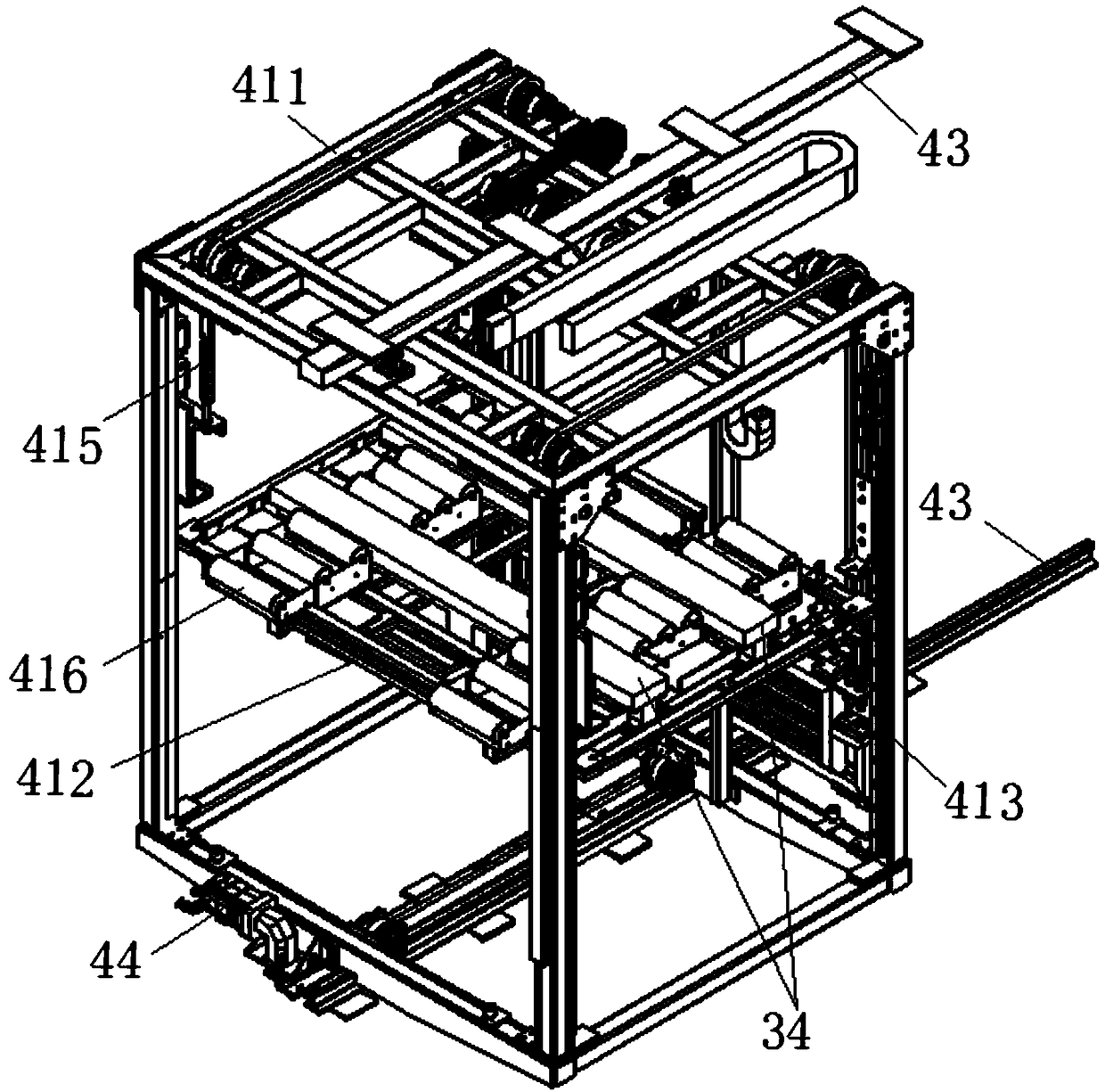

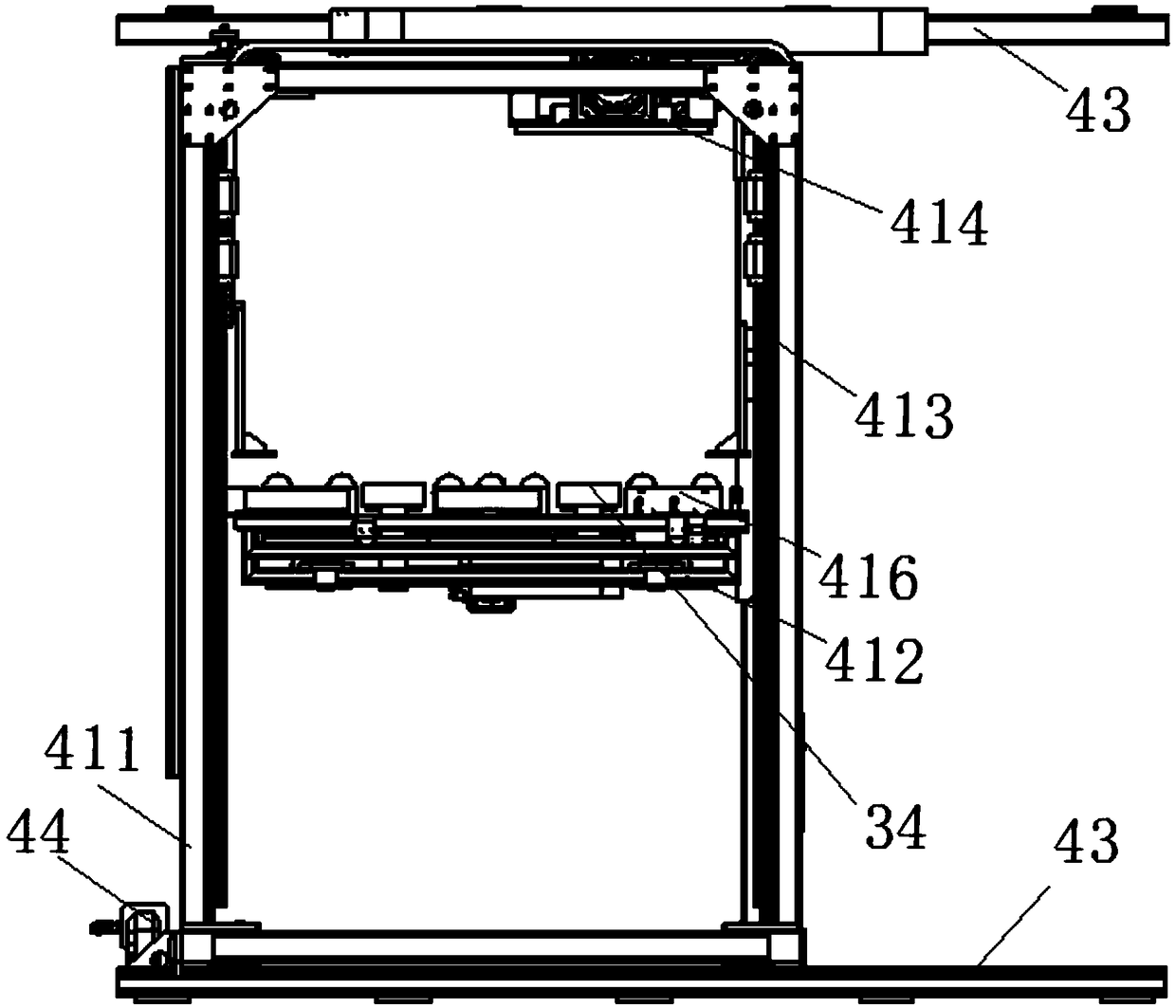

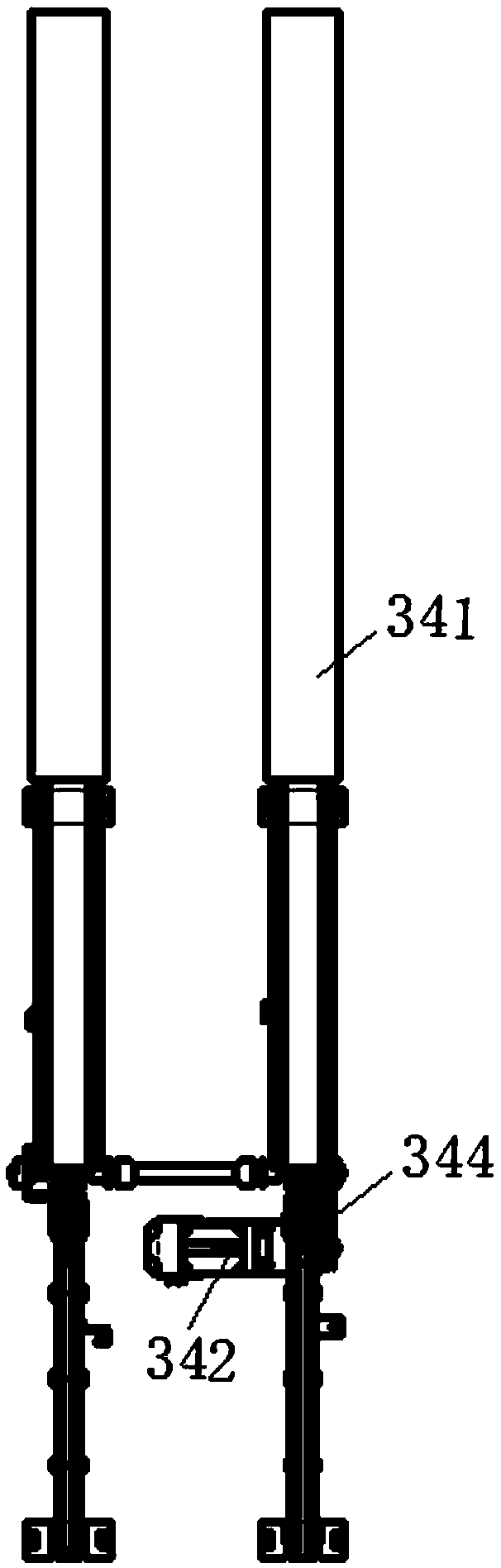

[0019] Embodiment: An elevating and connecting mechanism for a car exchange station, including a walking track 43, a moving drive device 44 for the elevating and connecting mechanism, a connecting main body frame 411, a connecting platform 412, a connecting platform lifting track 413 and a connecting platform lifting The driving device 414; the connecting main frame 411 is arranged on the walking track 43; the moving driving device 44 of the lifting connecting mechanism drives the connecting main frame 411 to move on the walking track 43; the connecting main frame 411 is set There is a connecting platform lifting track 413; the connecting platform lifting track 413 is provided with a connecting platform 412; the connecting platform lifting drive device 414 drives the connecting platform 412 to move up and down on the connecting platform lifting track 413; There are four lifting rails 413 for the connecting platform;

[0020] The upper surface of the connecting platform 412 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com