Self-weight quantitative powder feeding device applicable to laser remanufacturing

A technology of laser remanufacturing and powder supply device, applied in the field of powder supply device, can solve the problems of reducing the utilization rate of powder, sticking to the surface of the molten pool, accelerating surface solidification, etc., so as to improve the utilization rate of powder, stabilize powder supply, and reduce heat the effect of exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

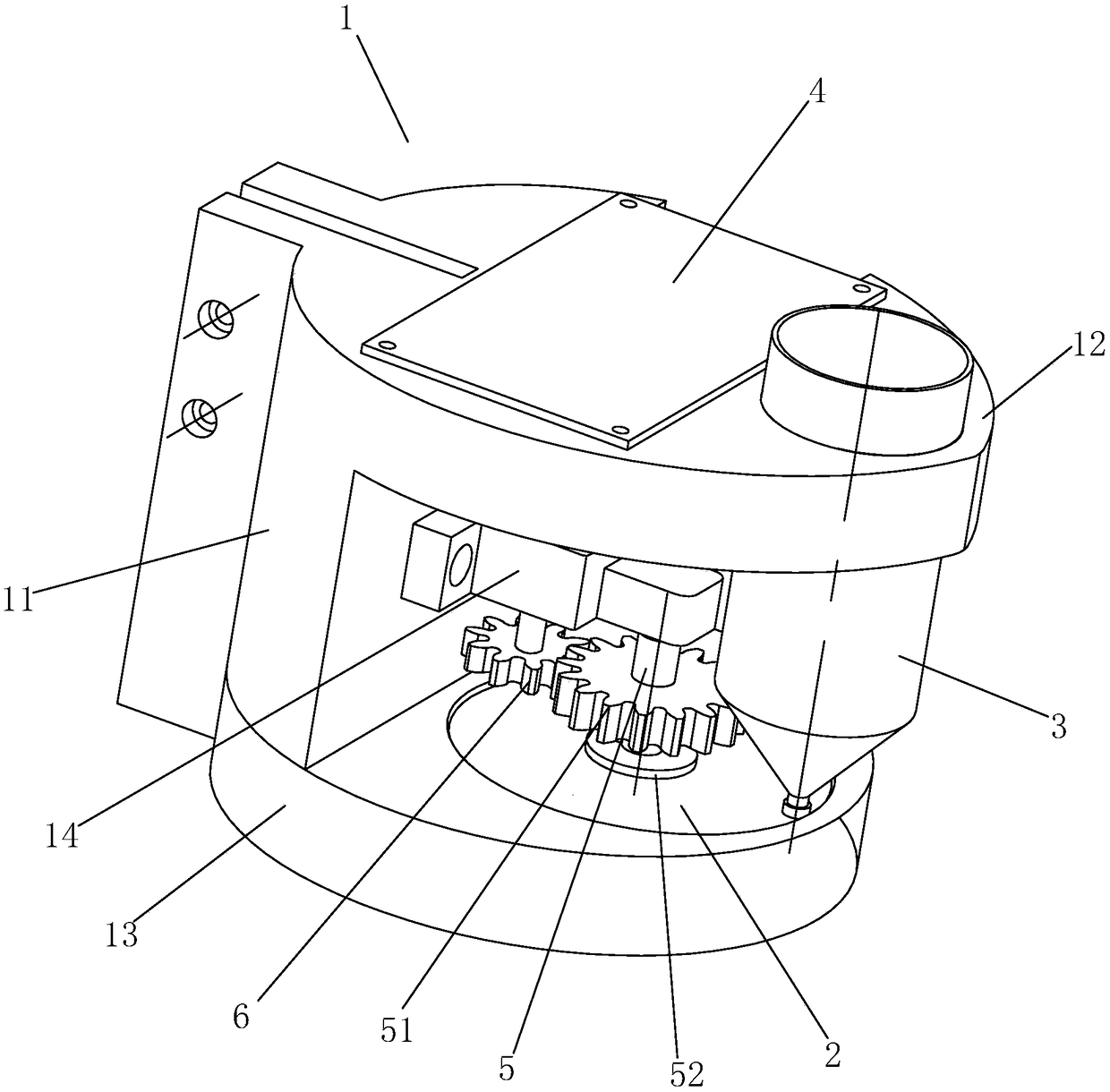

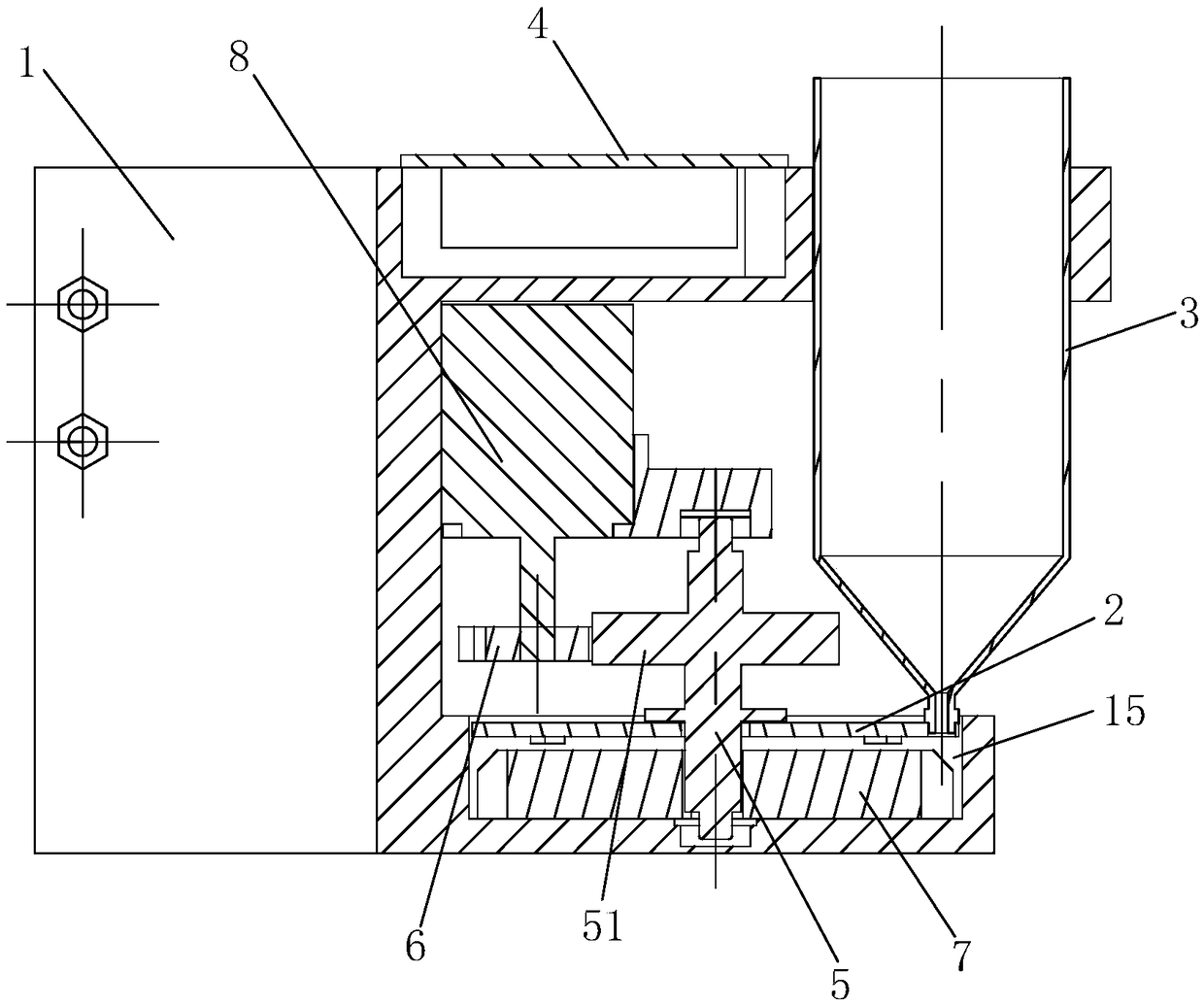

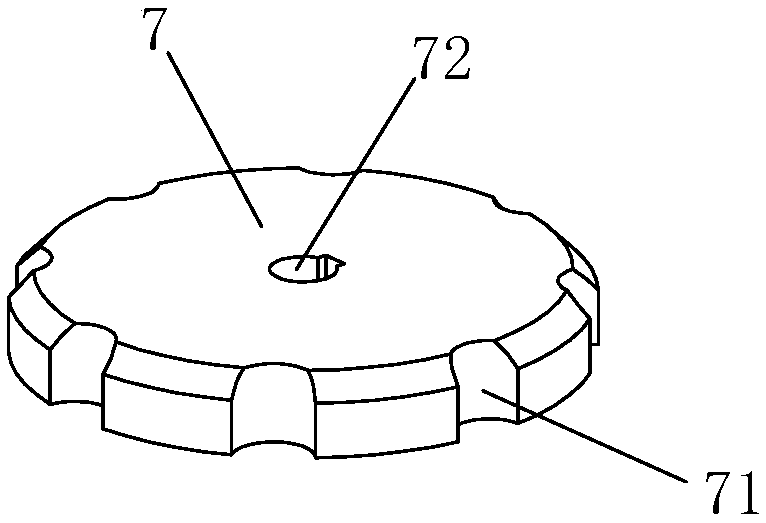

[0027] Examples, see Figure 1-Figure 7 As shown, a self-weight quantitative powder supply device suitable for laser remanufacturing of the present invention includes a body, a drive mechanism, a powder bucket 3, and a powder feeding plate 7. The body is provided with a rotary cavity 15, and the top of the rotary cavity 15 The powder inlet hole 21 on the surface and the powder outlet hole 131 running through the bottom surface of the rotary chamber 15, the powder inlet hole 21 and the powder outlet hole 131 are both deviated from the central axis of the rotary chamber 15, and the two are staggered up and down; the powder bucket 3 is arranged on the body , and the powder drop port at the bottom is connected to the powder inlet hole; the powder feeding disc 7 is rotatably arranged in the rotary chamber 15 around its axis, and is driven to rotate by the drive mechanism arranged on the body. The powder feeding plate 7 is evenly distributed along its circumference with several powd...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap