Film-forming method and film-forming apparatus

A film-forming method and film-forming device technology, which can be used in spraying devices, lighting devices, electrostatic spraying devices, etc., and can solve problems such as inappropriate inkjet methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, embodiments of the film forming method and film forming apparatus of the present invention will be described in detail with reference to the drawings.

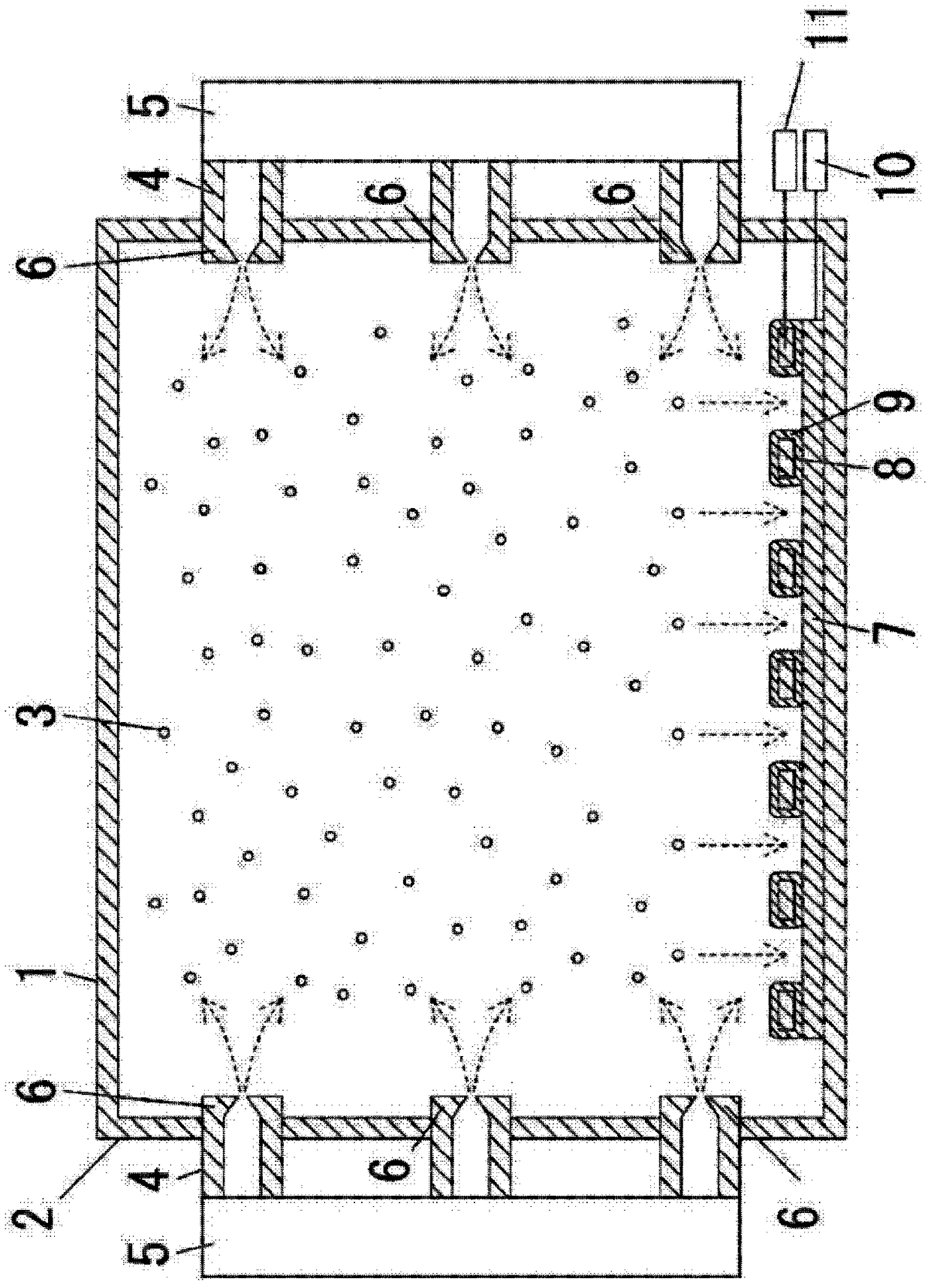

[0037] figure 1 In the figure, 1 is a tank, and the spraying device 5 which has the some nozzle 4 which sprays the microparticles|fine-particles 3 which are film-forming materials from the side wall 2 to the inside of the tank 1 is provided. From this spray device 5, through the piezoelectric element (not shown) that is used for spraying and the nozzle 4 of mesh shape (for example, diameter 1~5 μm, preferably make with the precision of 2.5±0.2 μm), particle diameter is 2~5 μm. Uniform particles 3 of 6 μm, preferably 3.3±0.2 μm, are sprayed into the tank 1 . 6 is a charging device for charging the microparticles 3 with, for example, a negative potential.

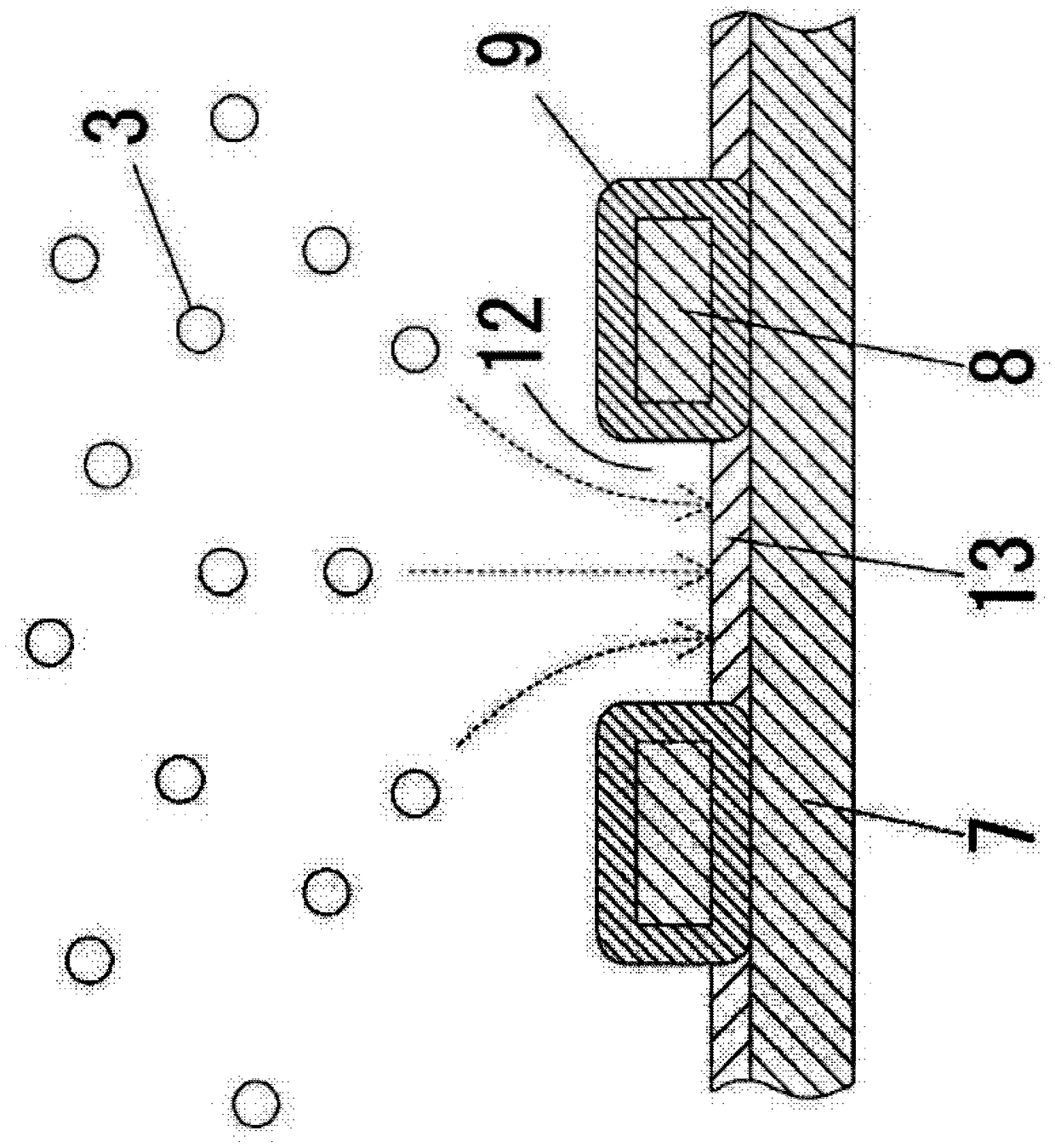

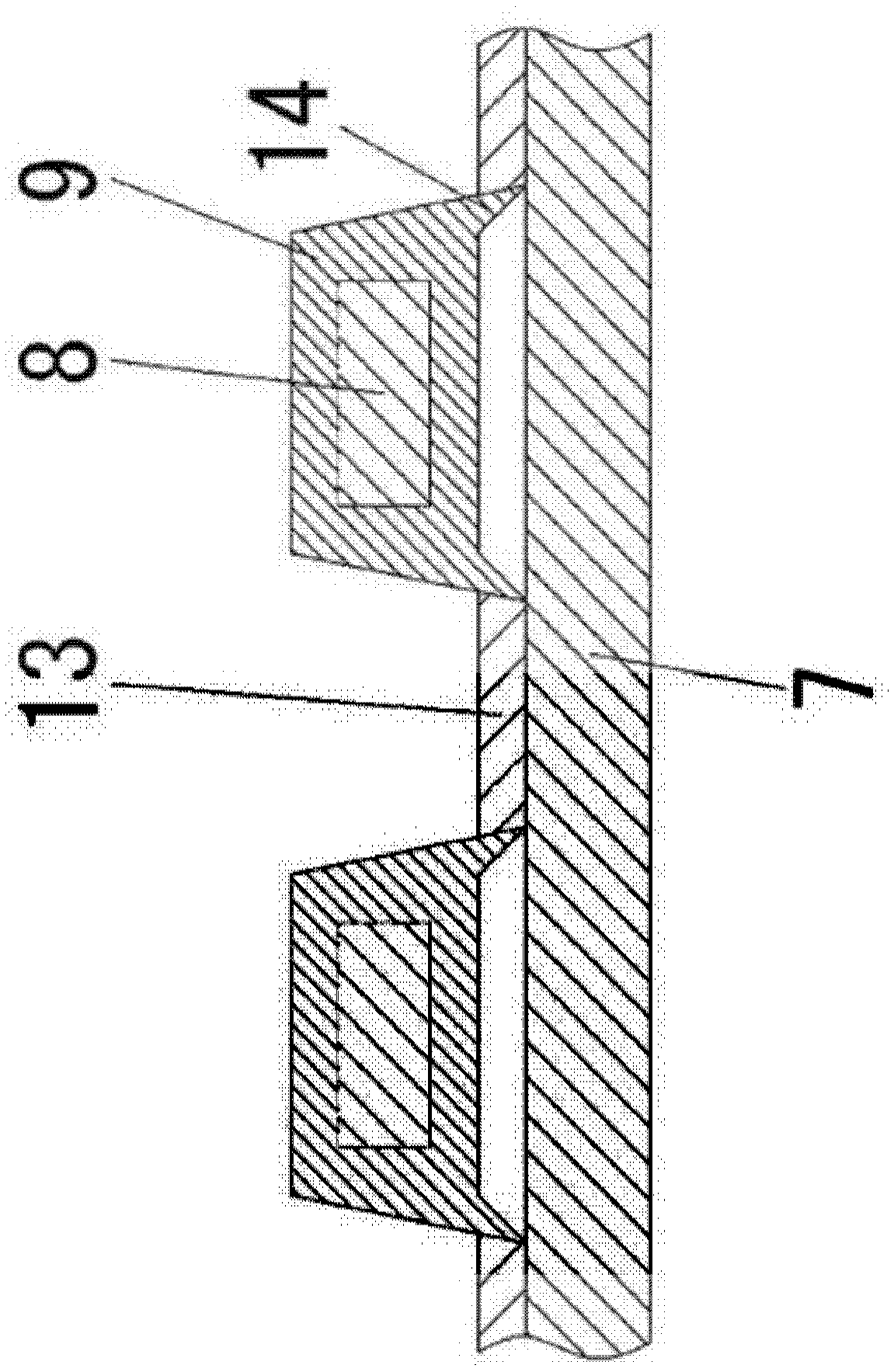

[0038] 7 is a substrate formed of a transparent body, which is provided at the bottom of the tank 1 . On this substrate 7, a mask 8 produced by electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com