Car shaft punching device

A technology for punching devices and automobile axles, which is applied in the direction of feeding devices, positioning devices, storage devices, etc., and can solve the problems of no way to clamp and fix automobile axles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

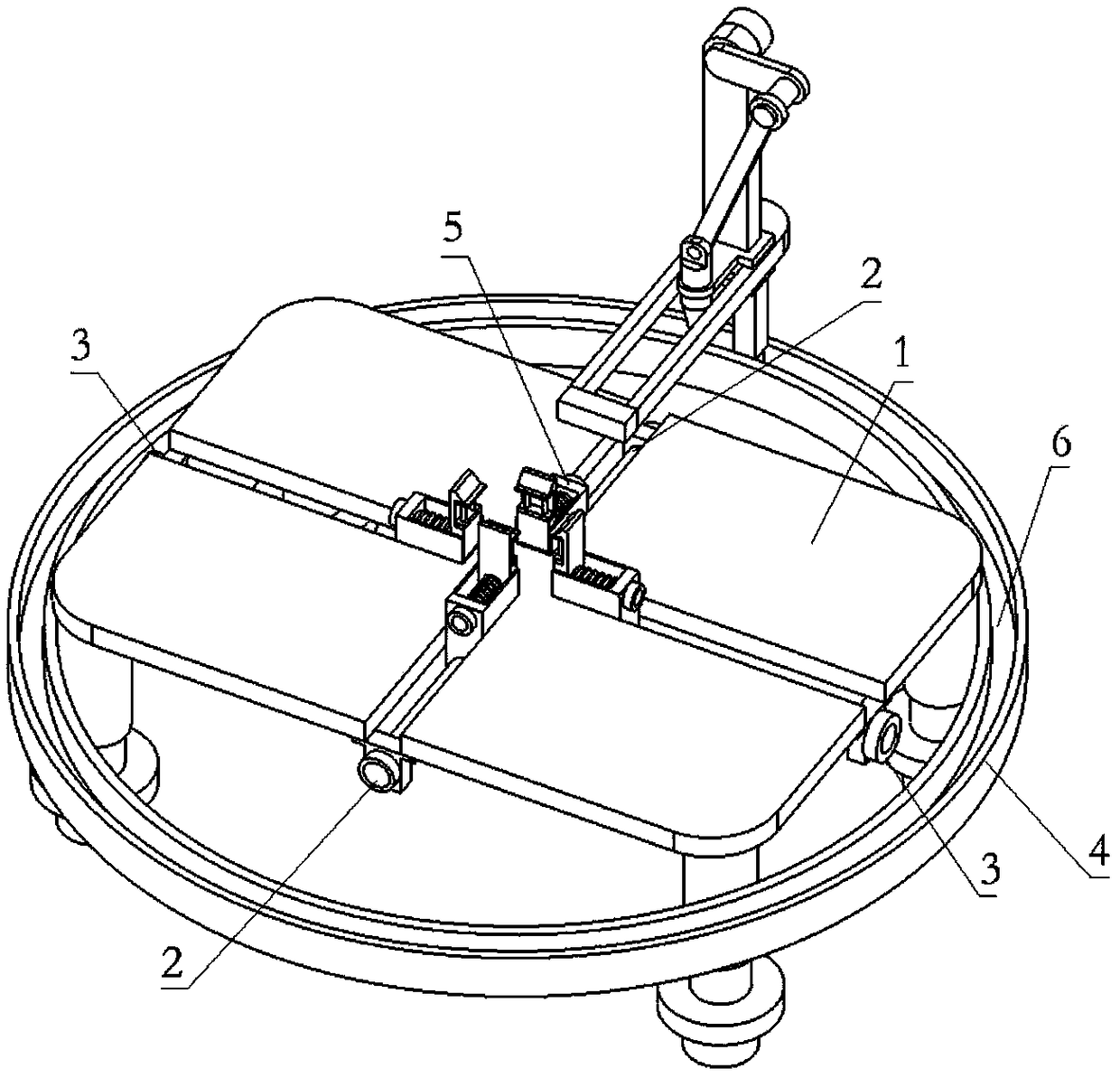

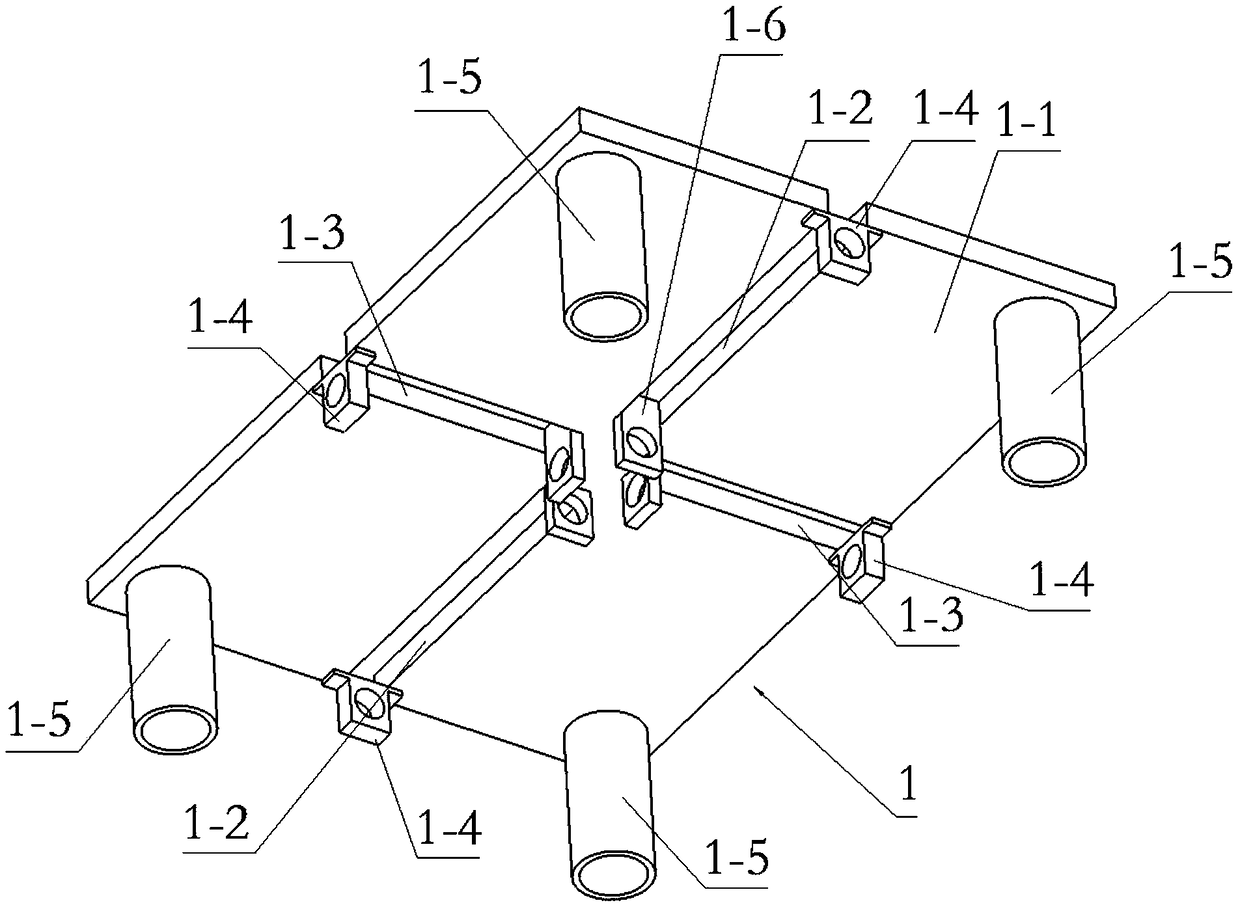

[0033] Combine below Figure 1-14 Describe this embodiment, a kind of punching device for automobile shafts, including a chassis body 1 and four clip bodies 5, the chassis body 1 includes a bottom plate 1-1, two longitudinal chute 1-2, two transverse Chutes 1-3, four hinged terminals 1-4, four bushings 1-5 and four inner hinged plates 1-6, two longitudinal chutes 1-2 are respectively arranged at the left and right ends of the bottom plate 1-1 , two transverse slide grooves 1-3 are respectively arranged at the front and rear ends of the bottom plate 1-1, four hinged terminals 1-4 are respectively fixedly connected to the middle ends of the four sides of the bottom surface of the bottom plate 1-1, and four bushings 1-5 are respectively fixedly connected to the four corners of the bottom surface of the bottom plate 1-1, and the four inner hinge plates 1-6 are respectively fixedly connected to the two longitudinal chute 1-2 and the two transverse chute 1-3. inner end;

[0034] T...

specific Embodiment approach 2

[0037] Combine below Figure 1-14 This embodiment will be described. This embodiment will further describe the first embodiment, the length of the longitudinal chute 1-2 is greater than the length of the horizontal chute 1-3.

specific Embodiment approach 3

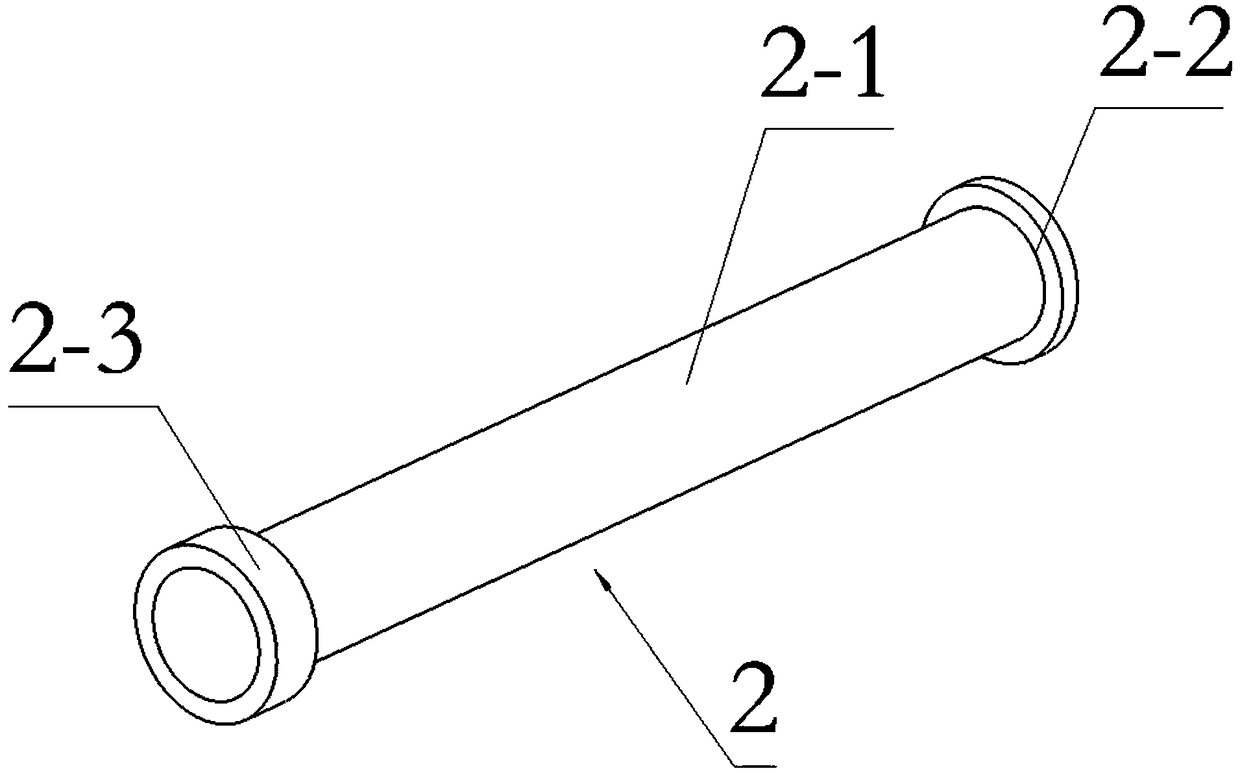

[0038] Combine below Figure 1-14 This embodiment will be described. This embodiment will further describe Embodiment 1. The transverse screw 2 includes a transverse screw body 2-1, a transverse boss 2-2 and a transverse runner 2-3, and the transverse boss 2-2 and the transverse The runners 2-3 are respectively fixedly connected to the two ends of the transverse screw body 2-1, and the inner ends of the two transverse screw bodies 2-1 are respectively rotatably connected to the inner hinge plates 1-6 on the front and rear sides of the bottom plate 1-1, The outer ends of the two transverse screw bodies 2-1 are respectively rotatably connected to the hinge terminals 1-4 on the front and rear sides of the base plate 1-1, and the inner hinge plates 1-6 and hinge terminals 1-4 on the front and rear sides of the base plate 1-1 Both are arranged between the transverse boss 2-2 and the transverse runner 2-3, and the clip bodies 5-1 in the two transverse chute 1-3 are connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com