Automatic stereoscopic storage device and method thereof

A kind of equipment and three-dimensional technology, applied in the field of warehouses, can solve the problems of bulky structure, no stability, unstable structure of lifting mechanism, etc., and achieve the effect of saving space, improving stability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

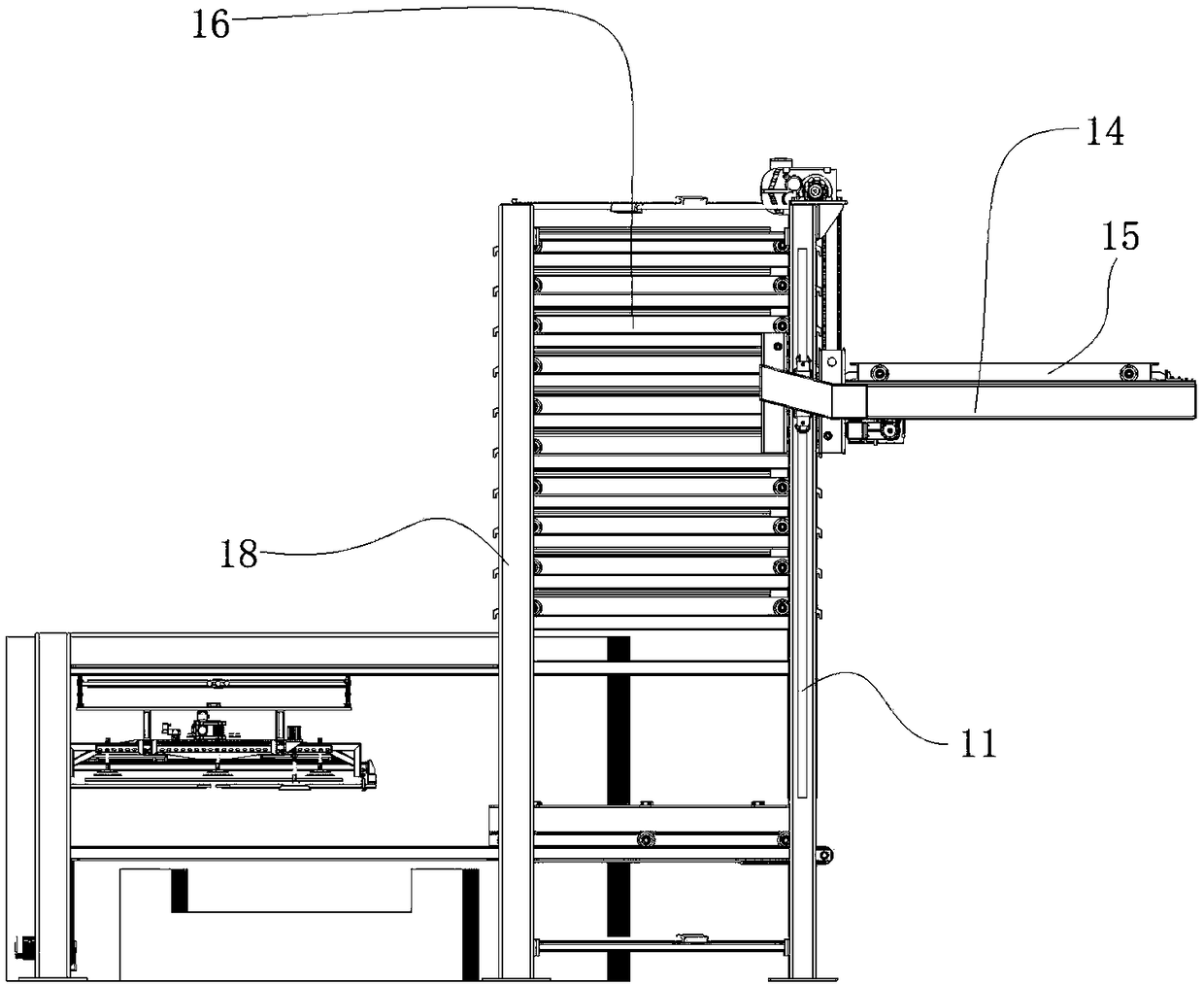

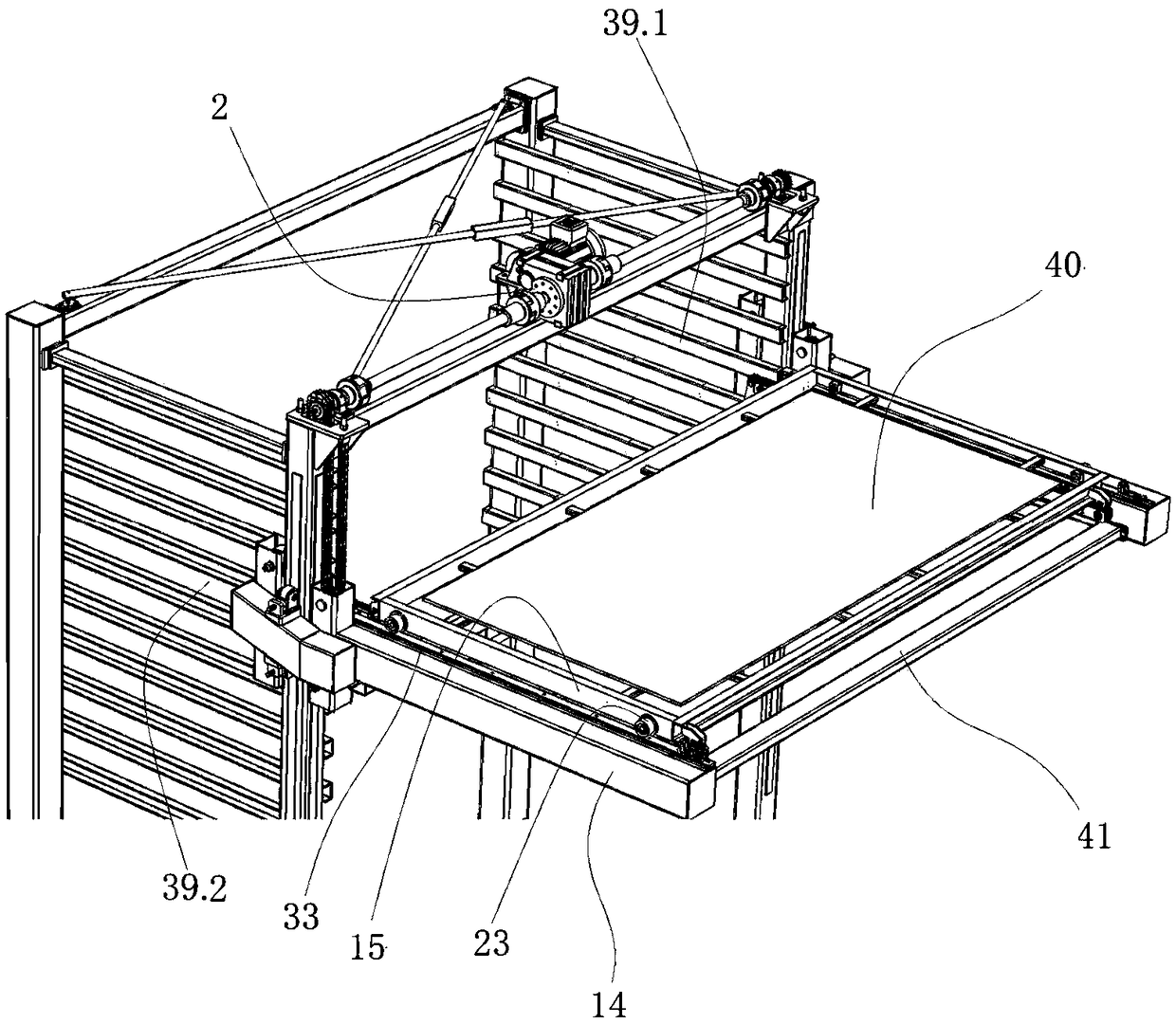

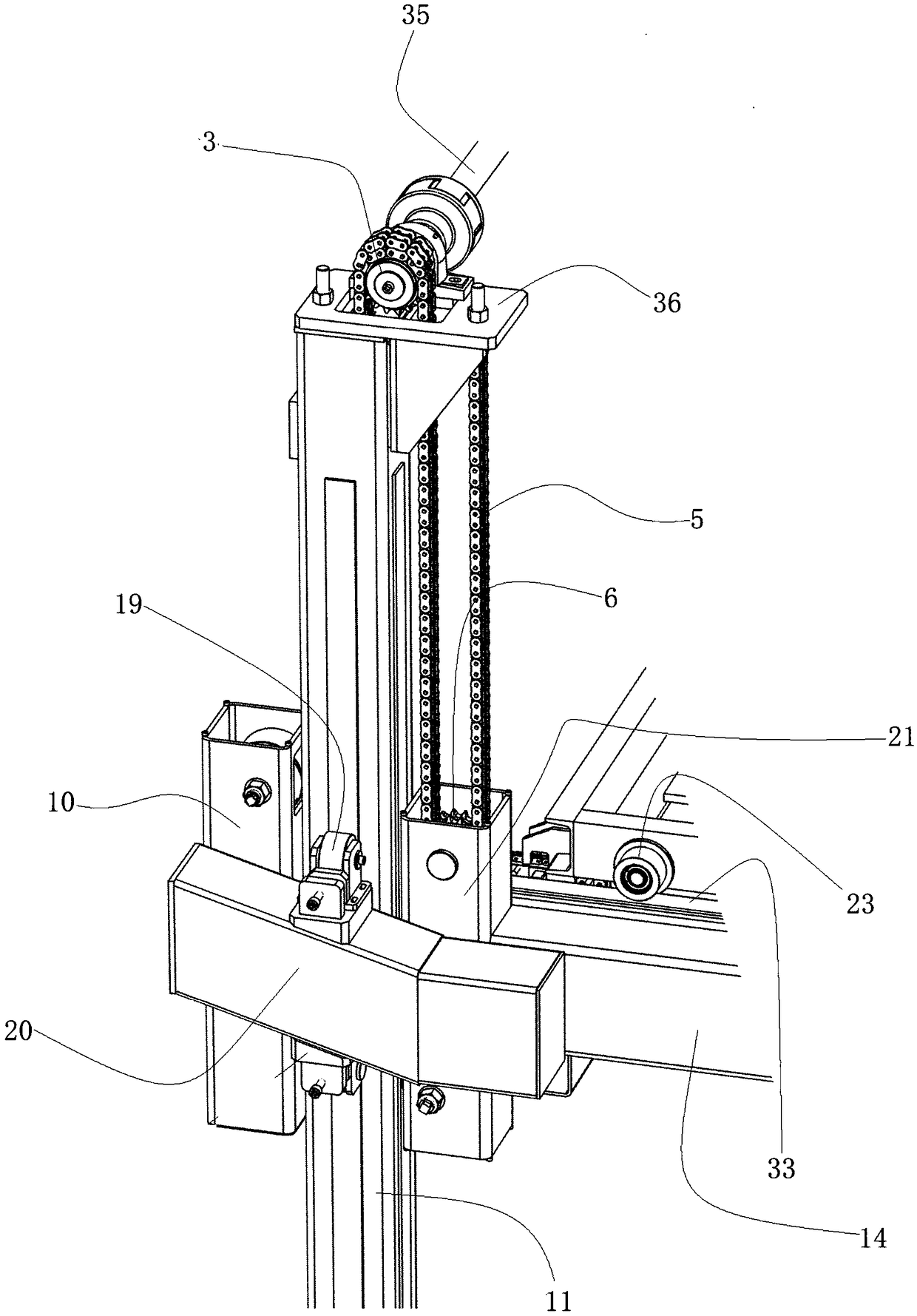

[0034] as attached Figures 1 to 11 The shown automatic three-dimensional storage equipment includes a vertical storage rack 16, and several groups of feeding cart brackets 39 are fixedly arranged in the vertical storage rack 16, and several groups of the feeding cart brackets 39 are arranged in a longitudinally spaced array A material truck 15 can be carried on the material vehicle bracket 39 of each group; a material vehicle lifting unit that can move up and down is provided on the front side of the vertical storage rack 16, and the material vehicle lifting unit can be displaced to successively Align the height of each group of material trolley brackets 39 , and the material trolley lifting unit can carry one material trolley 15 .

[0035] The vertical storage rack 16 includes four storage rack columns 18 in a rectangular array; among the four storage rack columns 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com