Novel drive structure

A technology of driving structure and driving mechanism, which is applied in the field of operation and transportation, can solve the problems of high height, high cost and maintenance cost, and the inability of AGV to achieve low-height lifting, and achieve the effect of low manufacturing cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

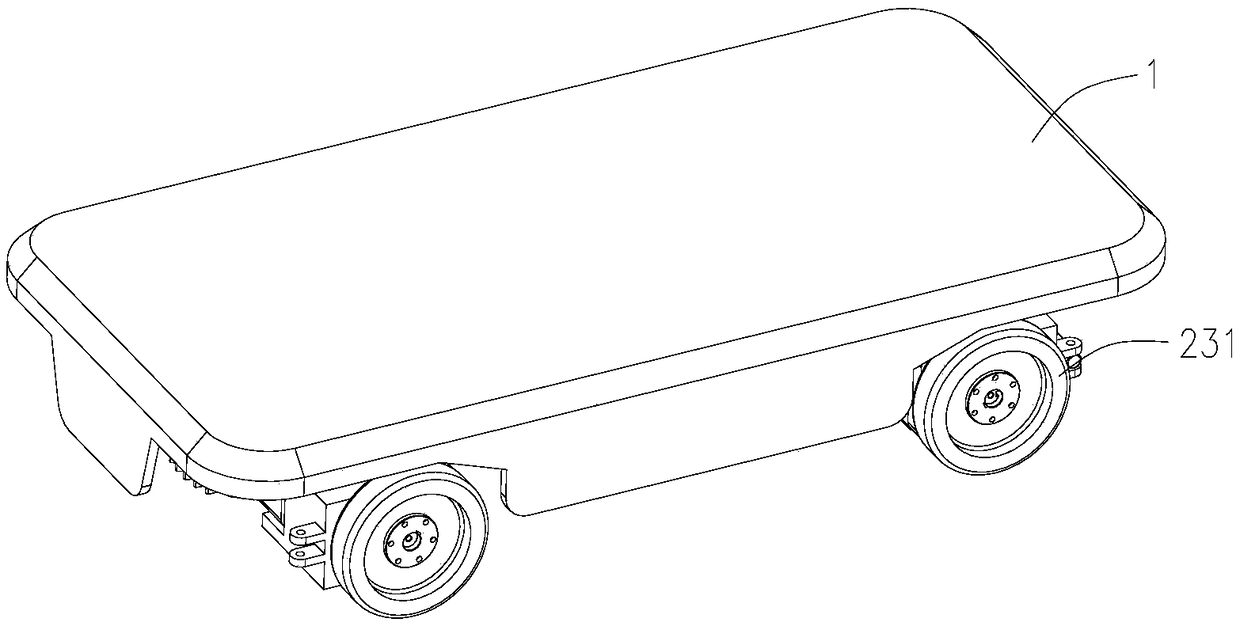

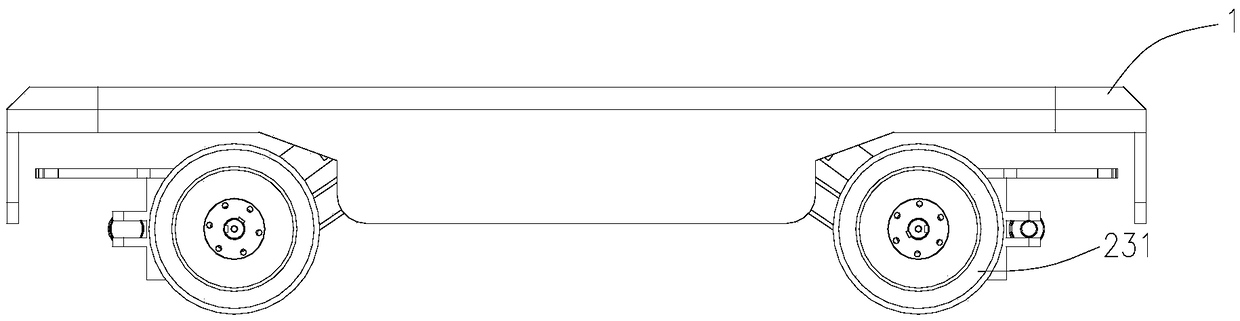

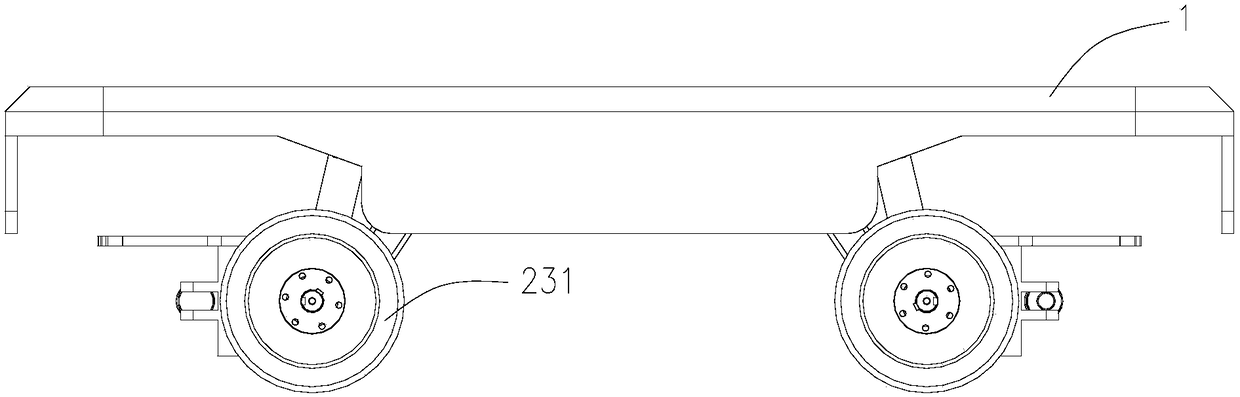

[0030] The technical scheme of the present invention is illustrated below in conjunction with accompanying drawing:

[0031] see Figure 1 to Figure 11 , the novel driving structure 2 of the present invention comprises a mounting bracket 21, a swinging bracket 24, a driving mechanism 22 and a driving device, the driving device is used to drive the driving structure 2 to advance, and the driving device includes a driving wheel 231 and a driving motor 232, the swing bracket 24 is provided with a synchronous structure; the swing bracket 24 is provided with two, the two swing brackets 24 are respectively hinged with the two ends of the installation bracket 21 and the two swing brackets 24 pass through The synchronous structure is connected, and the two oscillating brackets 24 are respectively provided with a driving device, and the driving mechanism 22 is used to drive one of the oscillating brackets 24 to rotate relative to the mounting bracket 21, and at the same time make the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com