A preparation method of magnesium-tin alloy plate with long-period structural reinforcement

A long-period structure, tin alloy technology, applied in the direction of metal rolling, metal rolling, metal rolling racks, etc., can solve the problems that cannot meet the requirements of military and civilian applications, and achieve enhanced mechanical properties, accurate technical parameters, The effect of advanced technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be further described below in conjunction with accompanying drawing:

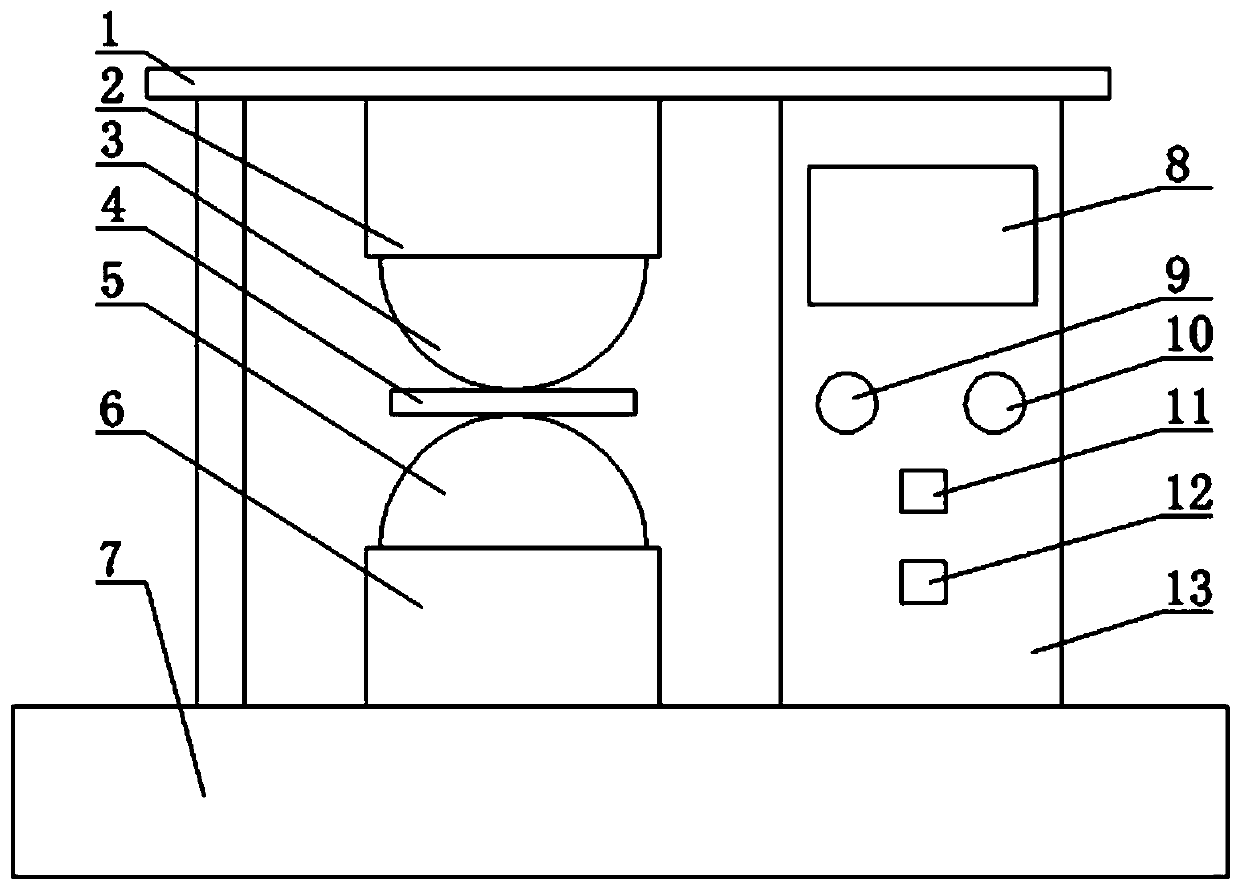

[0073] figure 1 As shown, it is the rolling state diagram of the magnesium-tin alloy sheet with long-period structural reinforcement. The positions of each part must be correct, set according to the amount, and operate in sequence.

[0074] The amount of chemical substances used in the preparation is determined according to the pre-set range in millimeters, milliliters, centimeters 3 is the unit of measurement.

[0075] The rolling of the magnesium alloy sheet is carried out on a two-roll mill, which is completed in the process of heating the slab, pressing the roll, and deforming the material;

[0076] The twin-roll mill is vertical, the upper right part of the twin-roll mill base 7 is the twin-roll mill electric control box 13, and the twin-roll mill electric control box 13 is provided with a twin-roll spacing regulator 8, a roll working indicator light 9, and a twin-ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com