Ellipsoid type reinforcing steel bar connecting piece

A connector, ellipsoid technology, applied in the direction of building components, building reinforcements, structural elements, etc., can solve the problems of destroying the overall performance of concrete components, difficult to operate, etc., to improve connection fastness, rapid construction, and avoid potential safety hazards. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further illustrate the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, but they should not be construed as limiting the protection scope of the present invention.

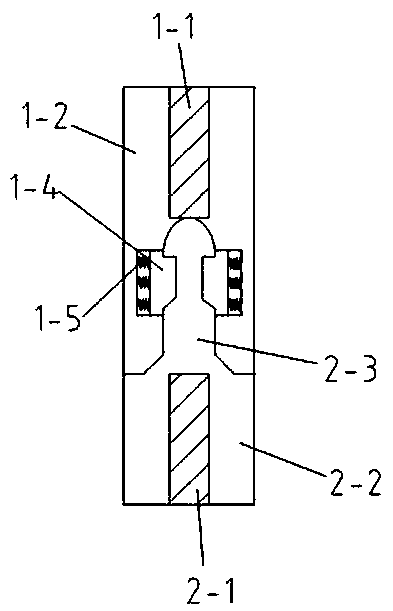

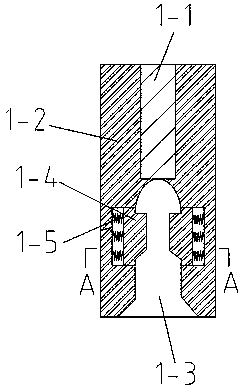

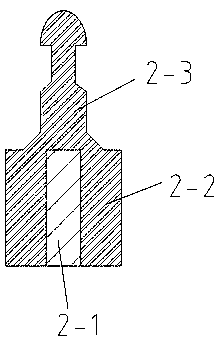

[0019] Such as figure 1 As shown, the present invention is an ellipsoid steel bar connector, which includes a lock head (1) and a lock body (2), and the end of the steel bar is processed into a thread shape.

[0020] Such as figure 2 , 4 , 8, the lock head (1) includes an upper sleeve (1-2), and the upper part of the upper sleeve (1-2) is provided with a bolt hole (1-1). Such as Figure 6 As shown, there is an empty slot (1-3) inside the upper sleeve (1-2), and the empty slot (1-3) consists of three parts: the upper ellipsoidal empty slot (1-3-1), the middle cylindrical The empty slot (1-3-2), the lower empty slot (1-3-3), the diameter of the upper ellipsoidal empty slot (1-3-1) is slightly larger than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com