Steel structure bridge connecting device

A connecting device and steel structure technology, applied in the direction of thin plate connection, connecting components, mechanical equipment, etc., can solve the problems of bolt fatigue fracture, weakening strength, changing the stress state of the structure, etc., so as to alleviate the sliding phenomenon, prevent the bolt from falling off, The effect of avoiding rigid failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further illustrate the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, but they should not be construed as limiting the protection scope of the present invention.

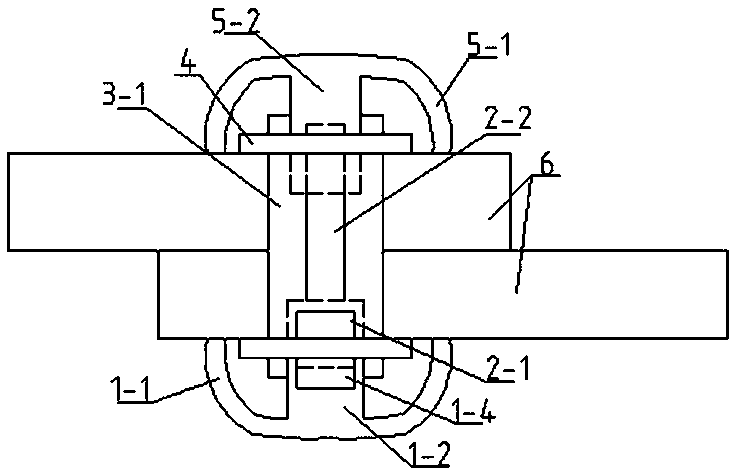

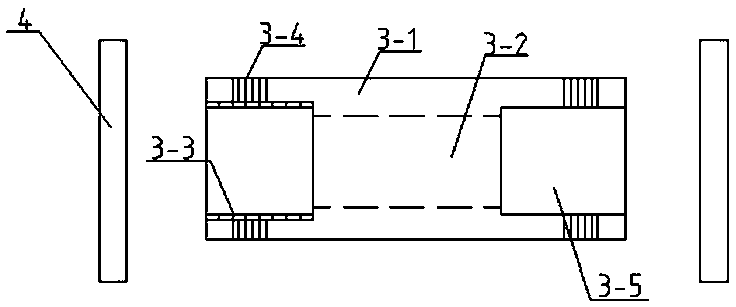

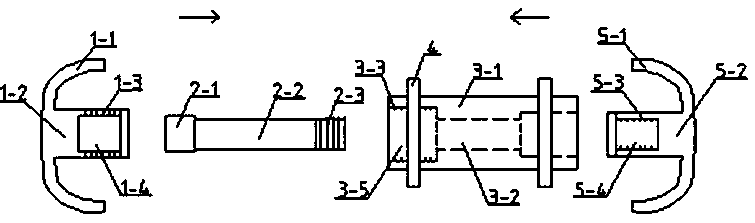

[0023] Such as Figure 1~3 As shown, a steel structure bridge connecting device of the present invention mainly comprises a left bolt cap, a bolt inner rod, a bolt outer rod, a nut, a right bolt cap, and the outside of the left bolt cap is a left friction cap 1-1, and the left friction cap 1-1 The bottom of the inner surface of -1, the thick screw 1-2 is vertically connected with the left friction cap 1-1, the center of the top axis of the thick screw 1-2 is set with the inner hole 1-4 of the thick screw, and the outer surface of the thick screw 1-1 forms a thick screw Thread 1-3, the head of the bolt inner rod is the plug head 2-1, the plug head 2-1 is connected with the bolt inner rod shaft 2-2, and the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com