Patents

Literature

72results about How to "Avoid rigid damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

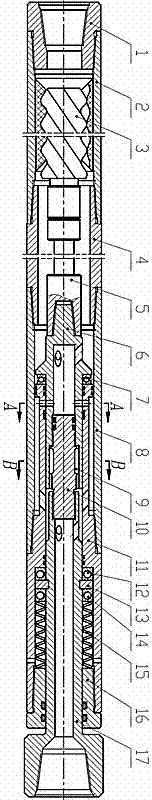

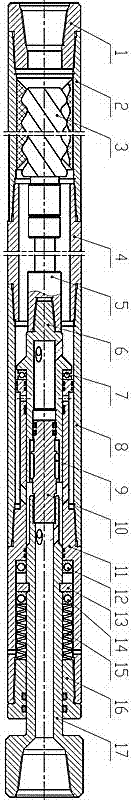

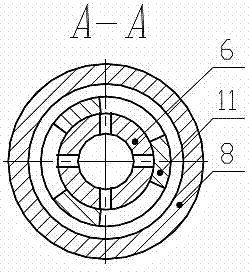

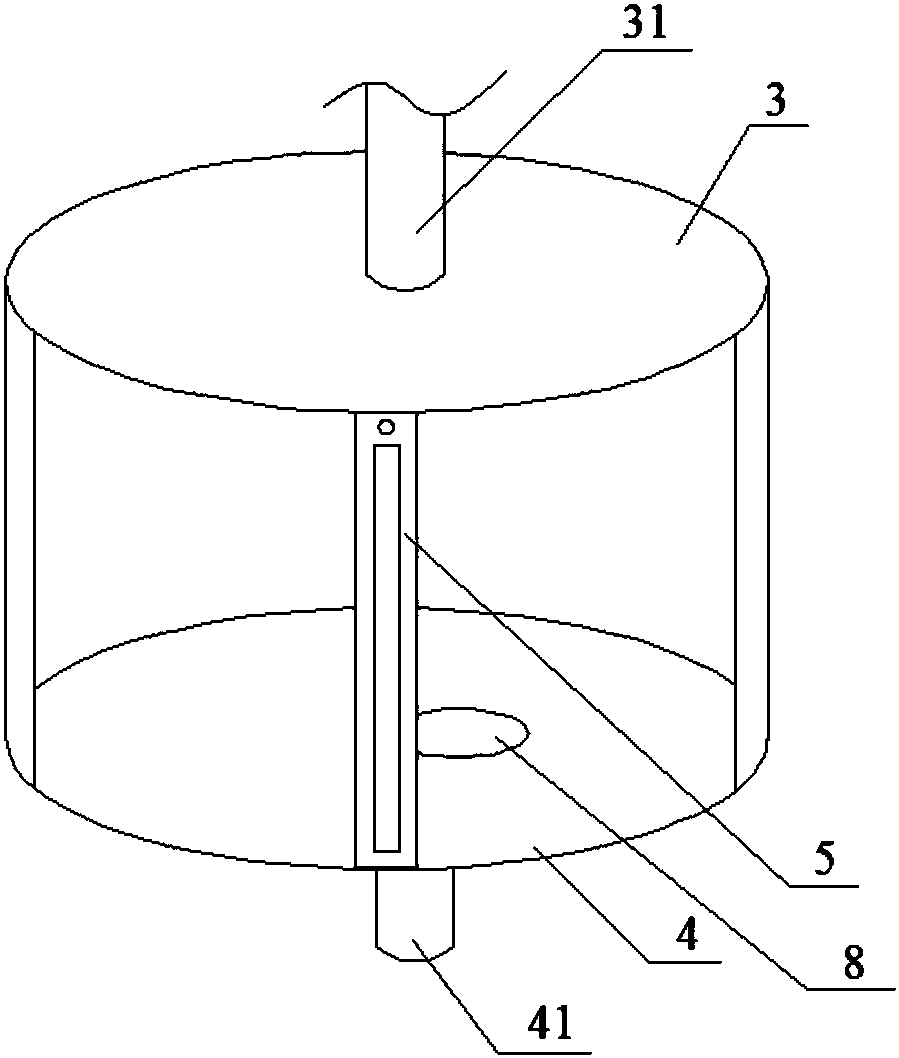

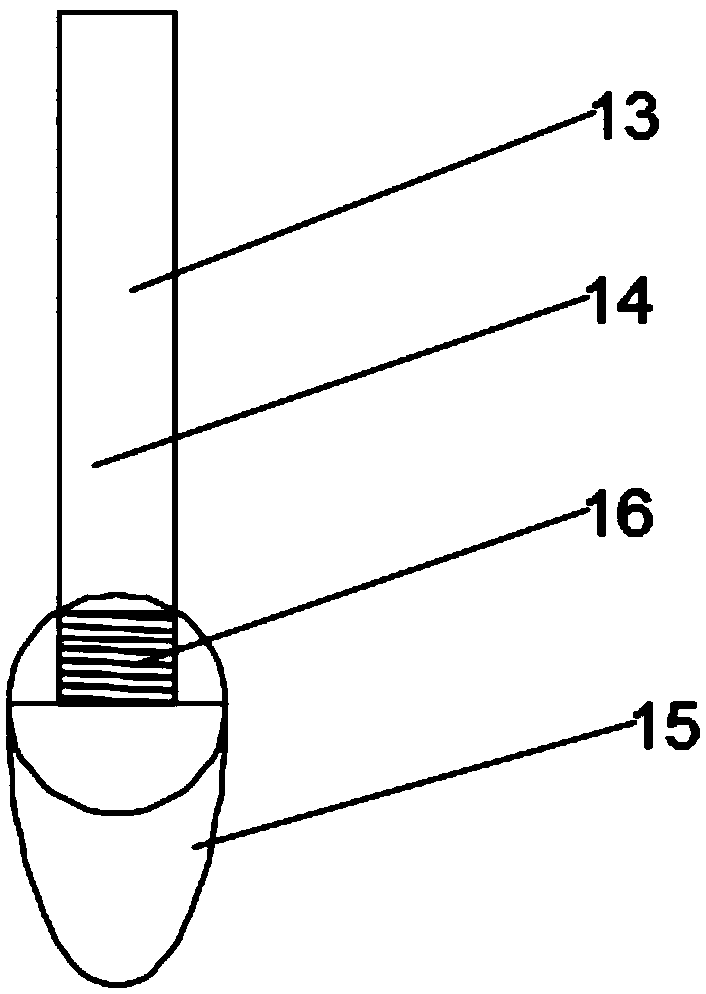

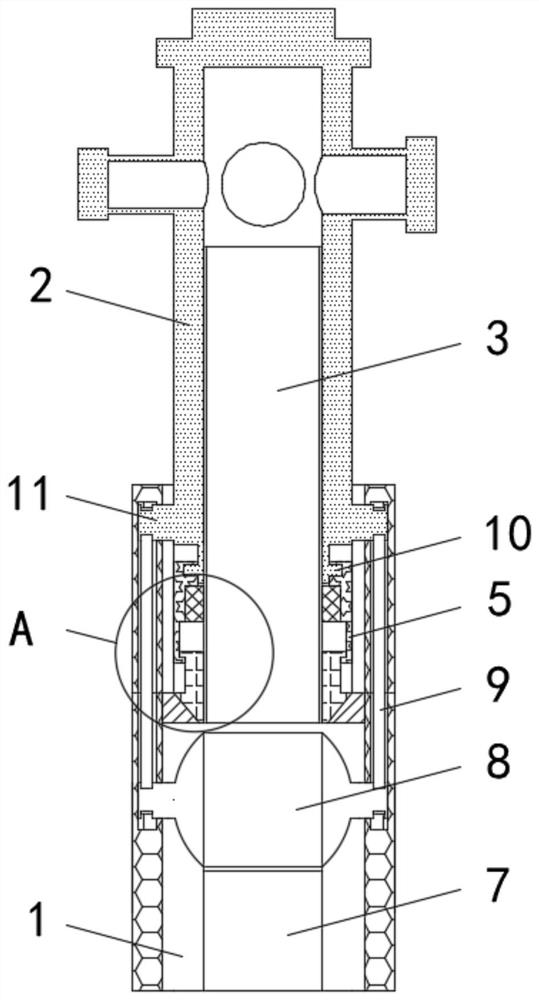

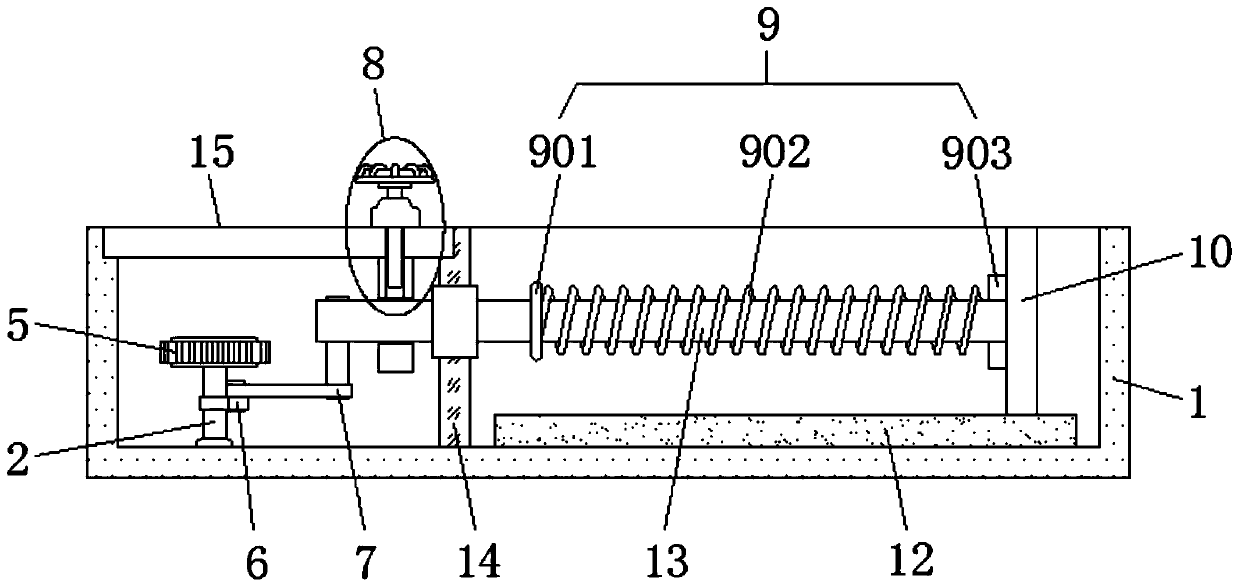

Hydraulic pulse type churn screw drill

InactiveCN106894755AImprove rock breaking efficiencyAvoid rigid damageBorehole drivesPistonGas industry

The invention relates to a hydraulic pulse type churn screw drill for accelerated drilling of deep wells and ultra-deep wells in petroleum and natural gas industry and solves the problems that drilling a hard formation is difficult and mechanical drilling speed is low during drilling process. According to the technical scheme, the hydraulic pulse type churn screw drill is characterized in that the upper end of a screw stator is in threaded connection with the lower end of an upper connector, the lower end of the screw stator is in threaded connection with the upper end of a universal shaft shell, a screw rotor is disposed in an inner cavity of the screw stator, the upper end of a universal shaft is in threaded connection with the lower end of the screw rotor, the lower end of the universal shaft is in threaded connection with the upper end of an upper shaft body, the upper end of a guide shell is in threaded connection with the lower end of the universal shaft shell, the lower end of the guide shaft is in threaded connection with the middle of a lower shell, an upper cylinder of a transmission piston is in clearance fit with the middle of an inner cavity of the upper shaft body, and the lower end of the transmission piston is in threaded connection with the middle of the lower shell. The hydraulic pulse type churn screw drill can generate rock-breaking torque and provide high-frequency axial impact, thereby improving bit's rock-breaking efficiency and mechanical drilling speed; the hydraulic pulse type churn screw drill is simple in structure and has few vulnerable parts.

Owner:SOUTHWEST PETROLEUM UNIV

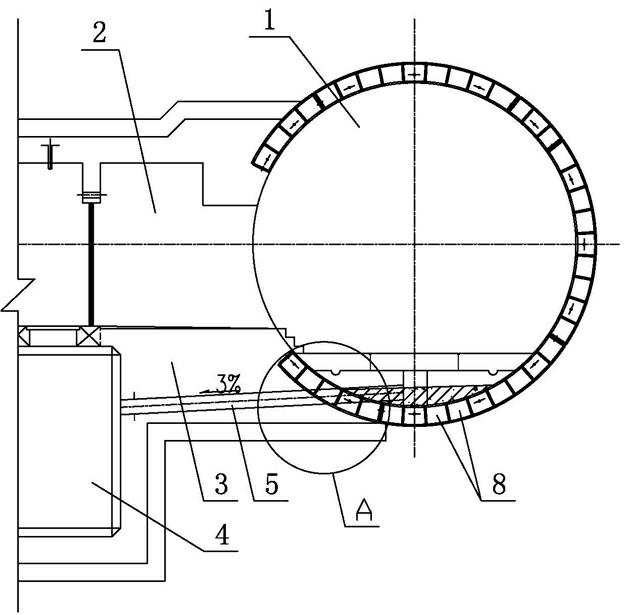

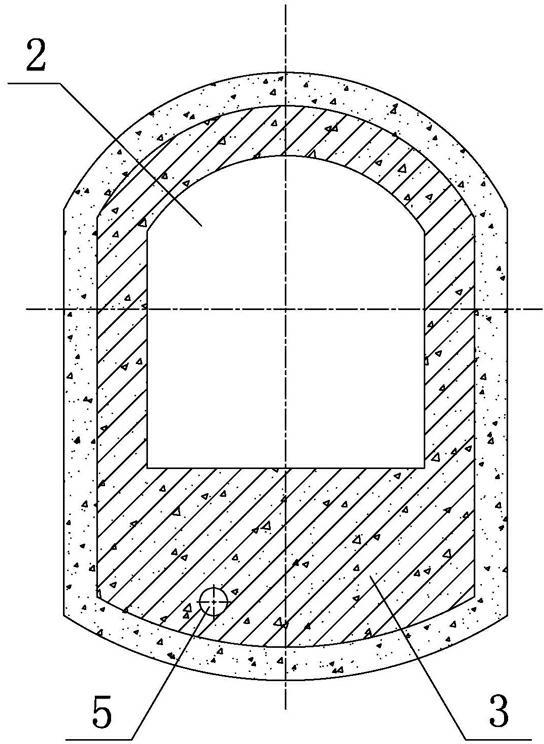

Contact tunnel also serving as pump station structure between shield tunnels and construction method thereof

InactiveCN102322292AAvoid rigid damageUniform and reasonable acceptanceUnderground chambersDrainageStructure of the EarthBuilding construction

The invention relates to a contact tunnel also serving as a pump station structure between shield tunnels and a construction method thereof. The invention aims to provide the contact tunnel also serving as the pump station structure between the shield tunnels, which has a simple structure and is convenient to construct, and the construction method thereof, in order to optimize the structure form of the contact tunnel and reduce the danger of engineering construction. The invention adopts the technical scheme that: the contact tunnel also serving as the pump station structure between the shield tunnels comprises a passageway communicating an upper tunnel with a lower tunnel, wherein a concrete bottom plate is cast at the bottom of the passageway; a sunk pump house is arranged at the bottom of the passageway; and a discharge pipe communicating a tunnel with the pump house is arranged at the bottom of the tunnel. The contact tunnel is characterized in that the discharge pipe is arranged in rock soil below the bottom plate. The contact tunnel and the construction method are applied to the construction of the underground shield tunnels.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

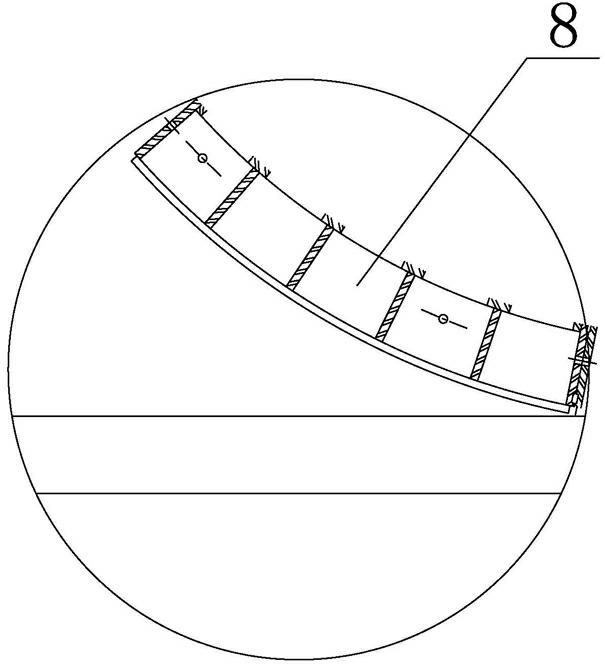

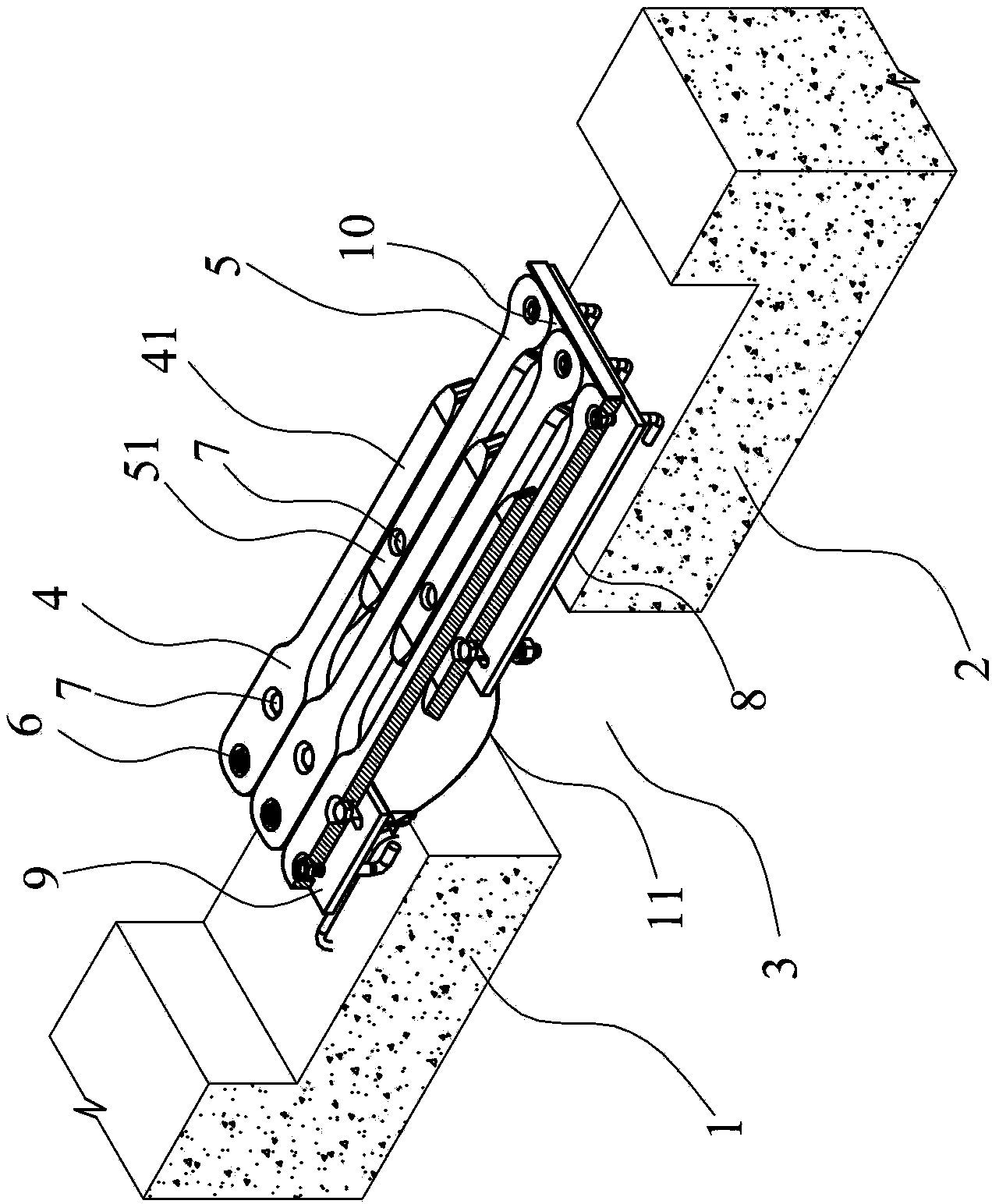

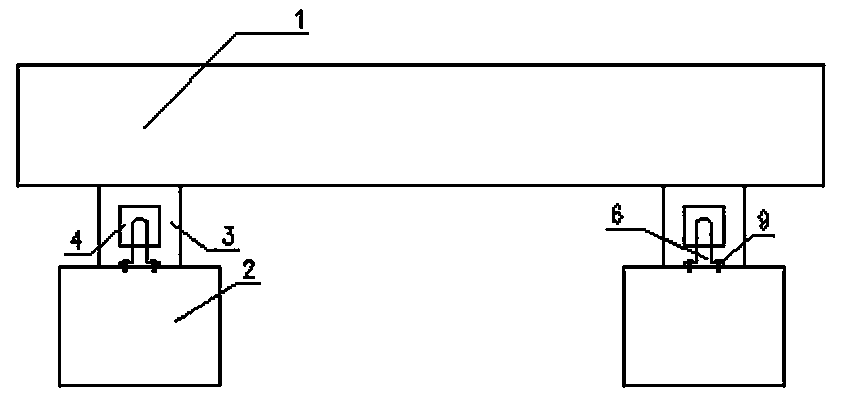

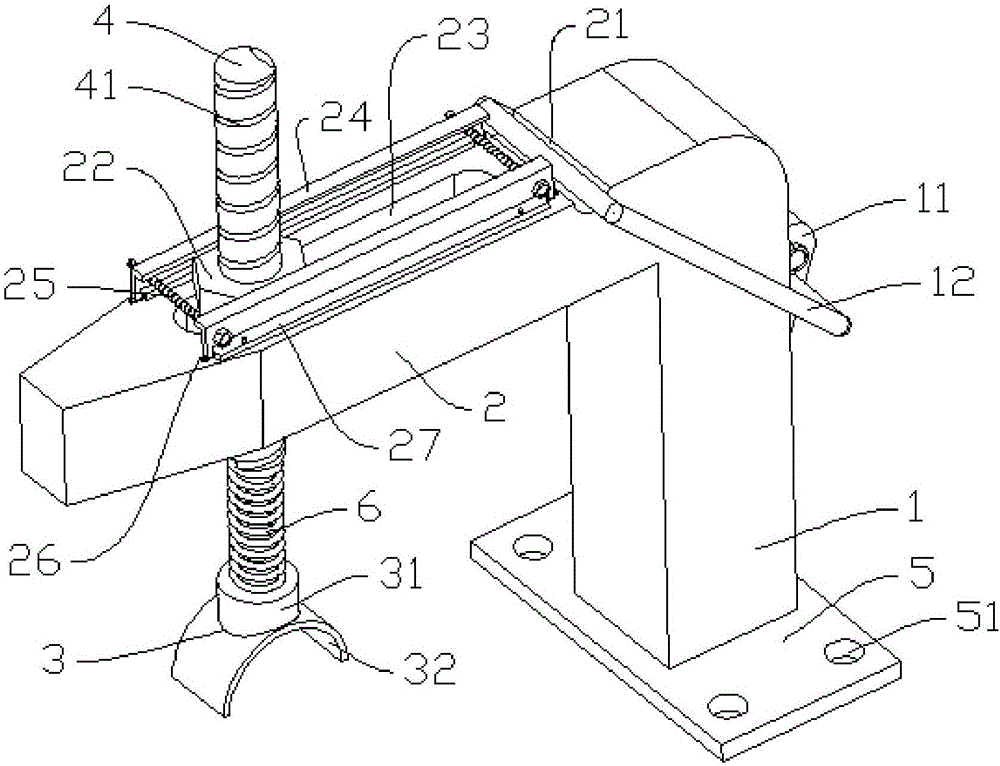

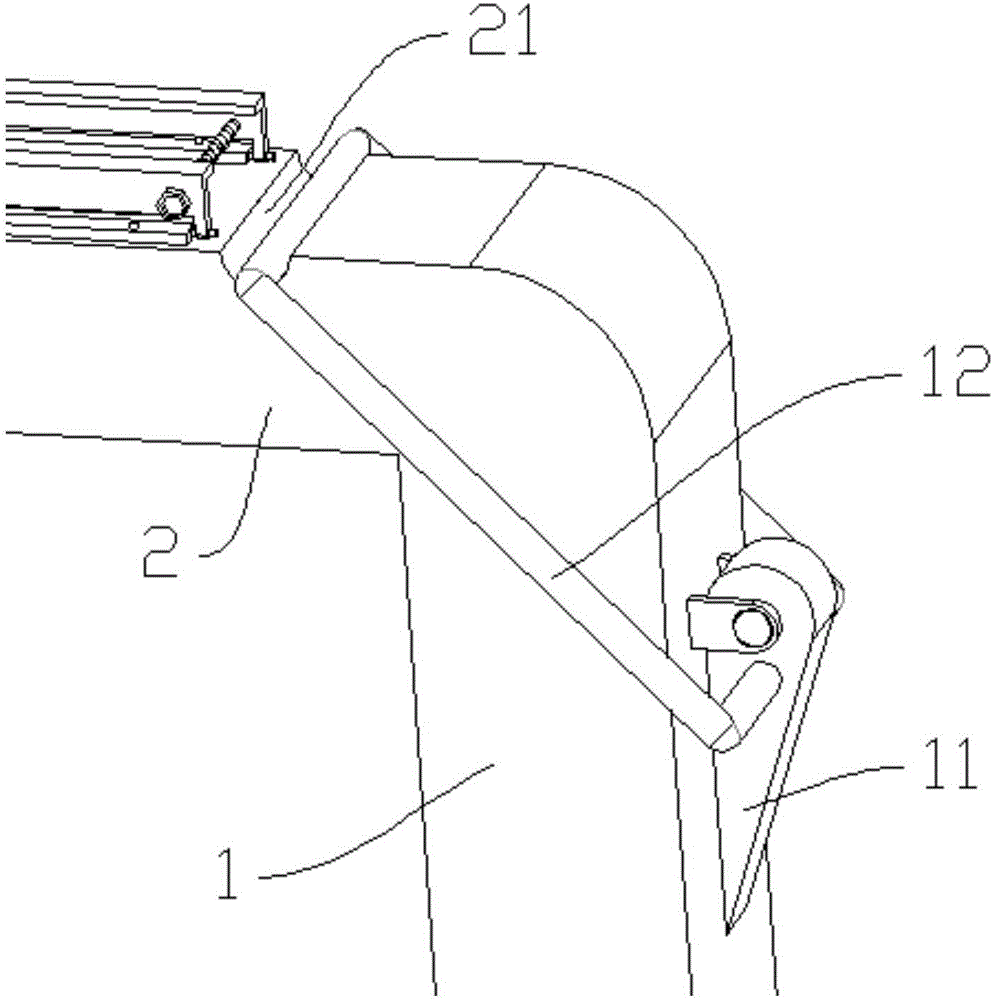

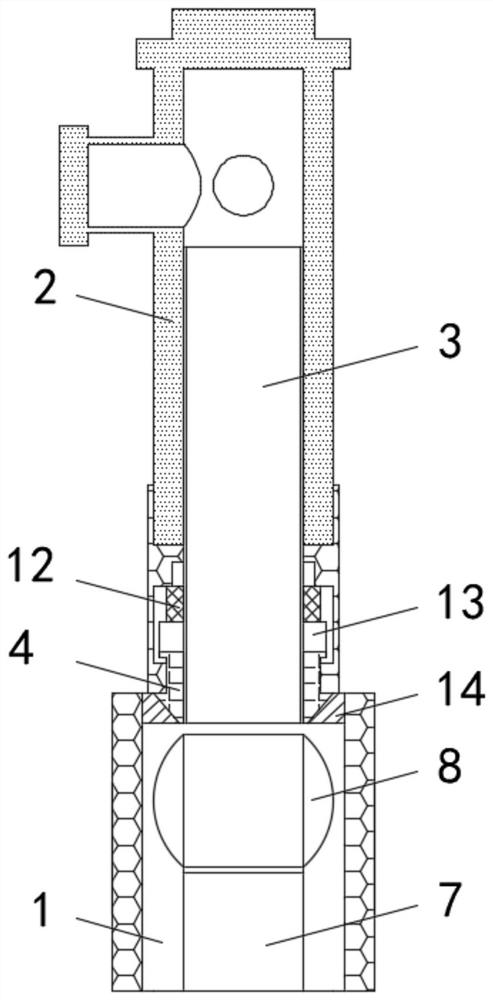

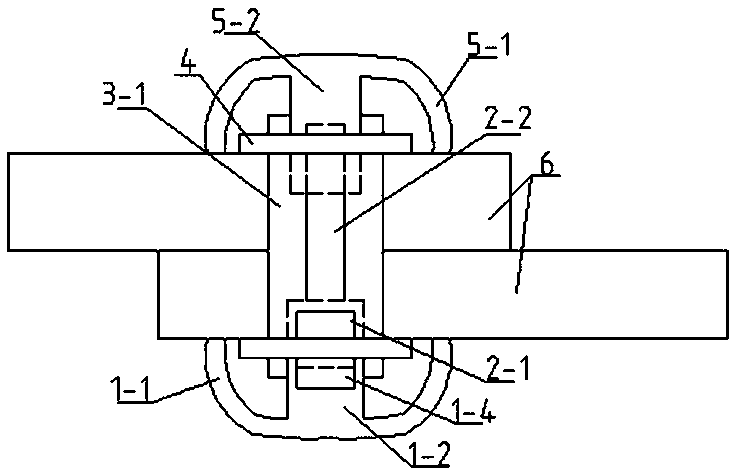

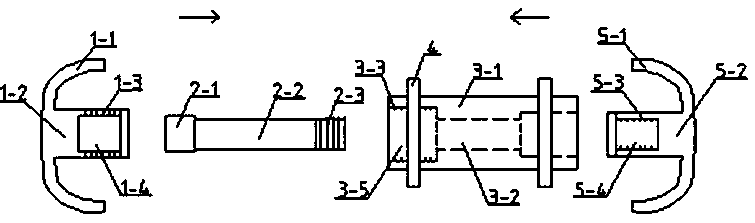

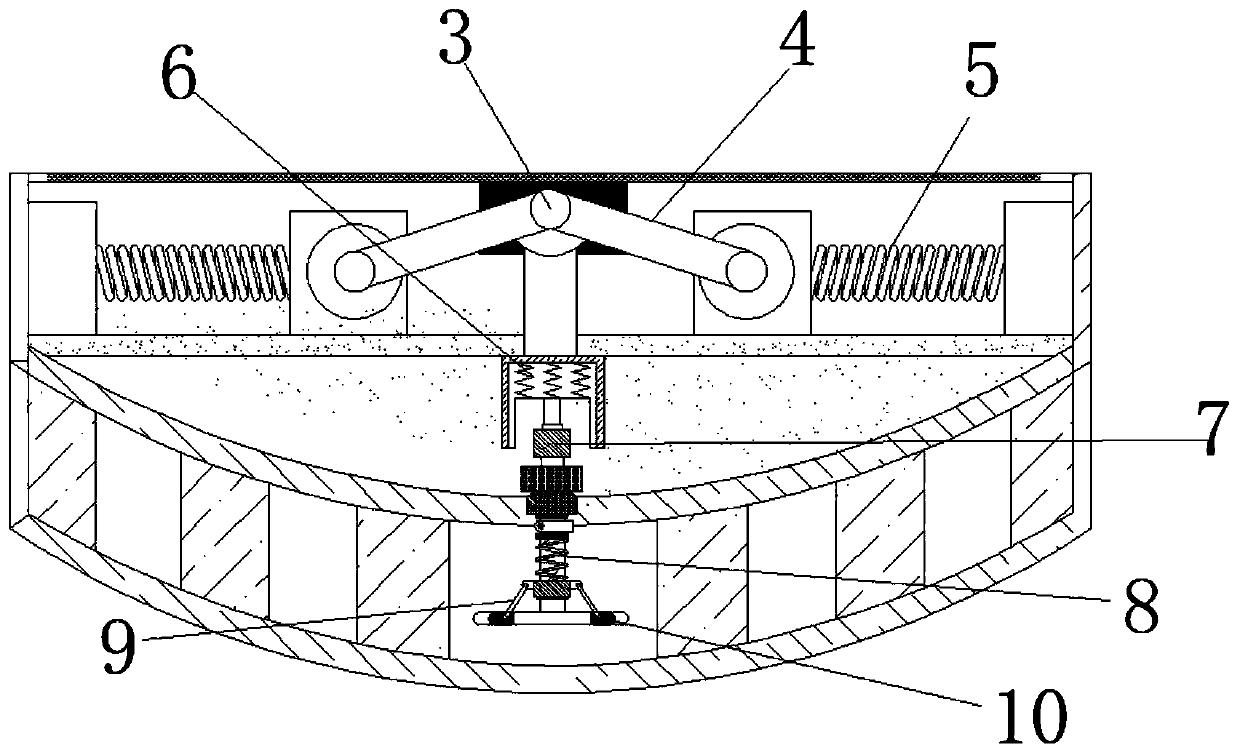

Anti-earthquake-displacement bridge expansion joint device

ActiveCN103352423AAvoid rigid damageImprove seismic performanceBridge structural detailsShock resistanceExpansion joint

The invention discloses an anti-earthquake-displacement bridge expansion joint device. The anti-earthquake-displacement bridge expansion joint device comprises a first movable comb plate and a second comb plate, wherein the first movable comb plate and the second comb plate are arranged on a first beam body and a second beam body which are located on the two sides of a bridge expansion joint respectively, comb teeth are arranged on the opposite ends of the first movable comb plate and the second movable comb plate respectively, the comb teeth are arranged in a crossing mode at intervals, the first movable comb plate stretches across the bridge expansion joint so that the tail ends of the comb teeth of the first movable comb can be located above the second beam body, and the first movable comb plate and the second movable comb plate are arranged on the first beam body and on the second beam body respectively in a mode that the first movable comb plate and the second movable comb plate can rotate horizontally relative to the beam bodies. Compared with the prior art, the anti-earthquake-displacement bridge expansion joint device has the advantages that rigid damage on the comb plates and on the whole bridge expansion joint device when earthquake displacement occurs can be effectively avoided, and the shock resistance of the expansion joint device is improved.

Owner:NINGBO ROABY TECH INDAL GROUP

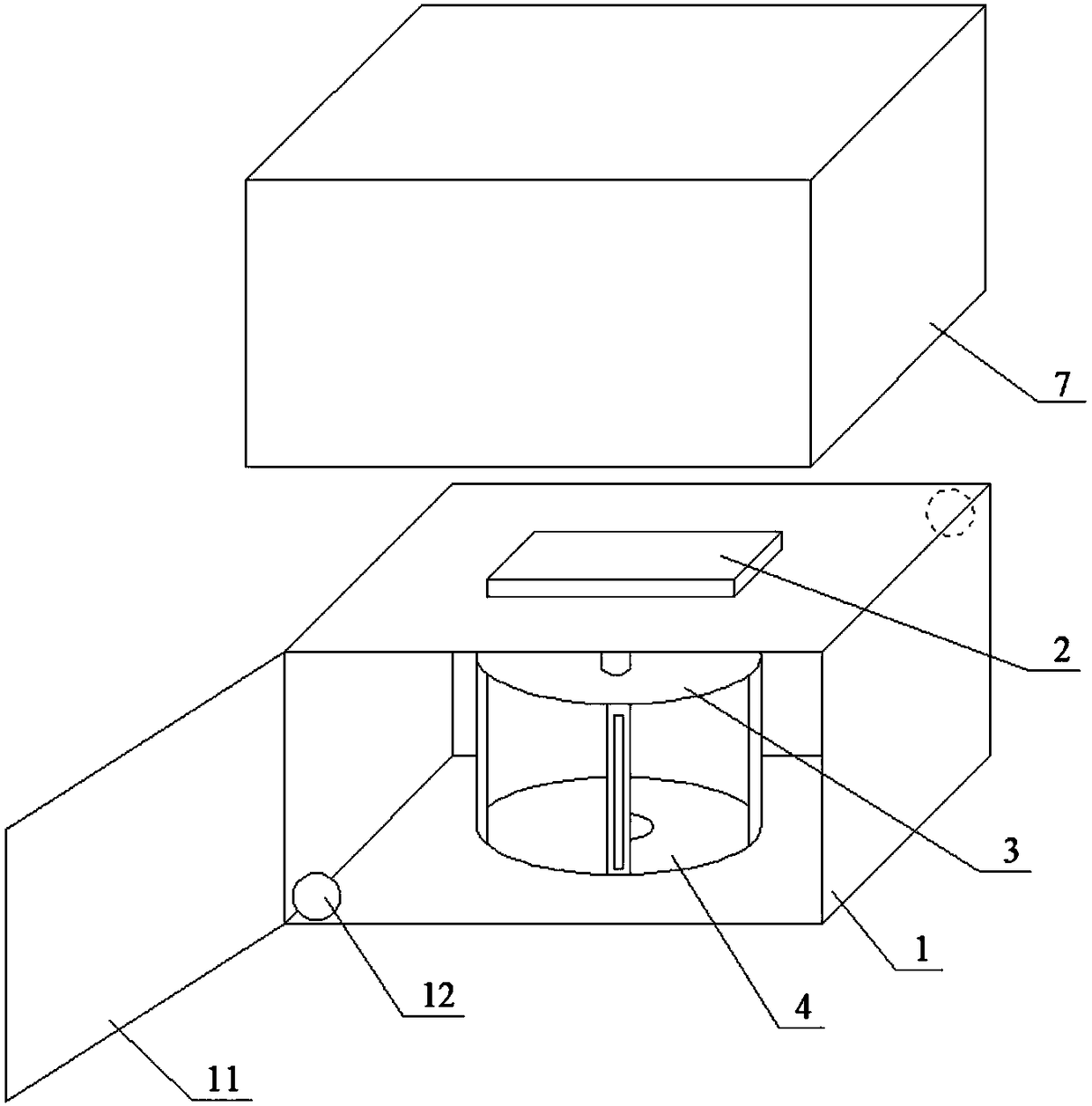

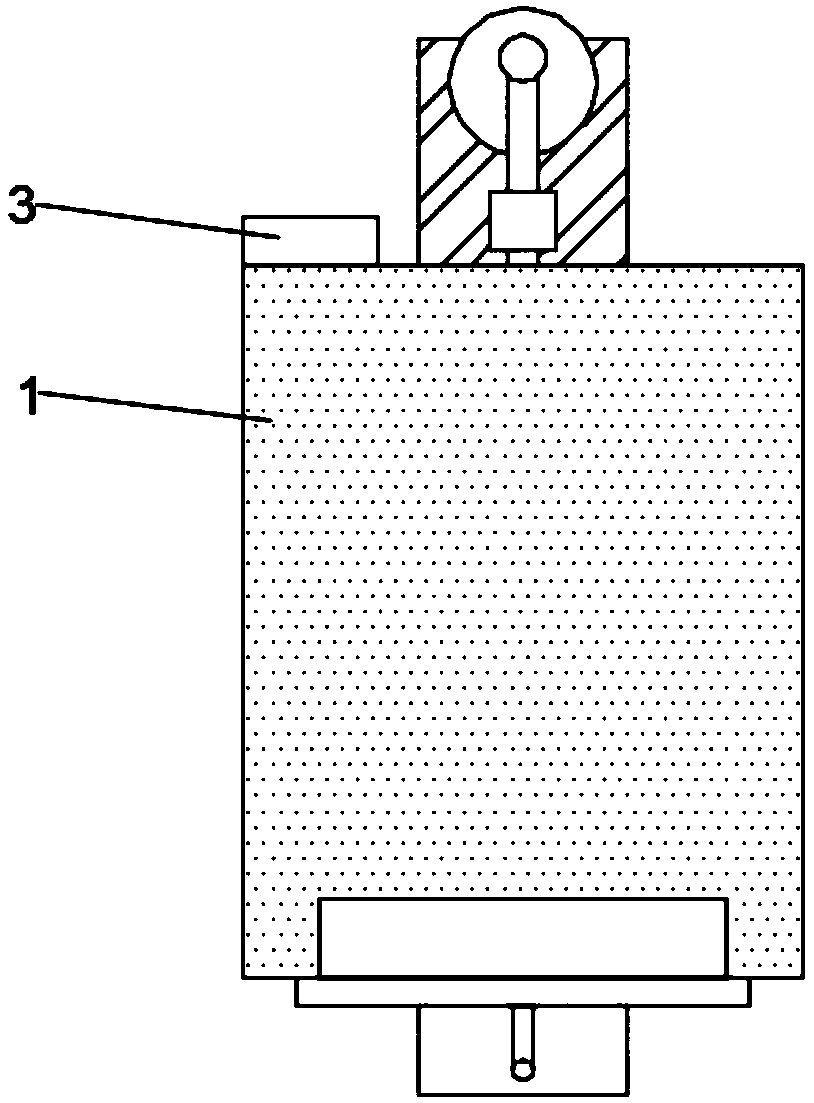

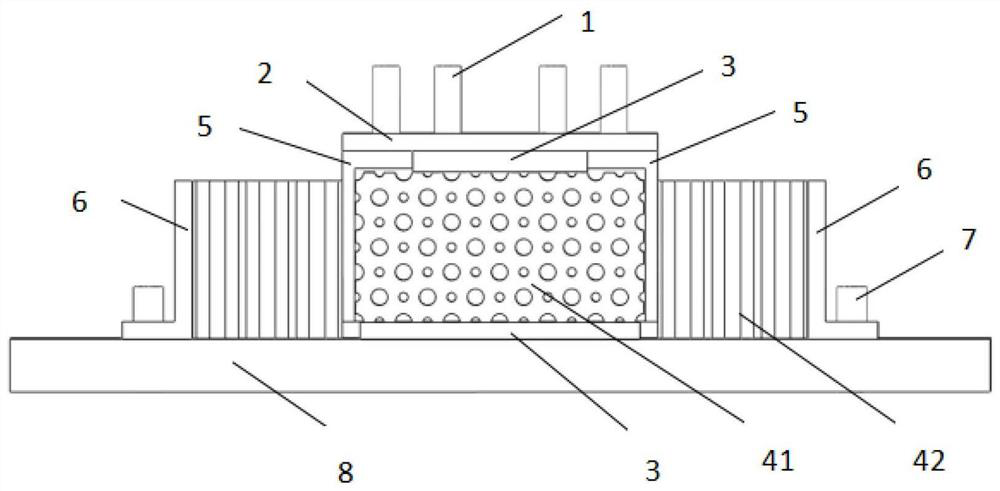

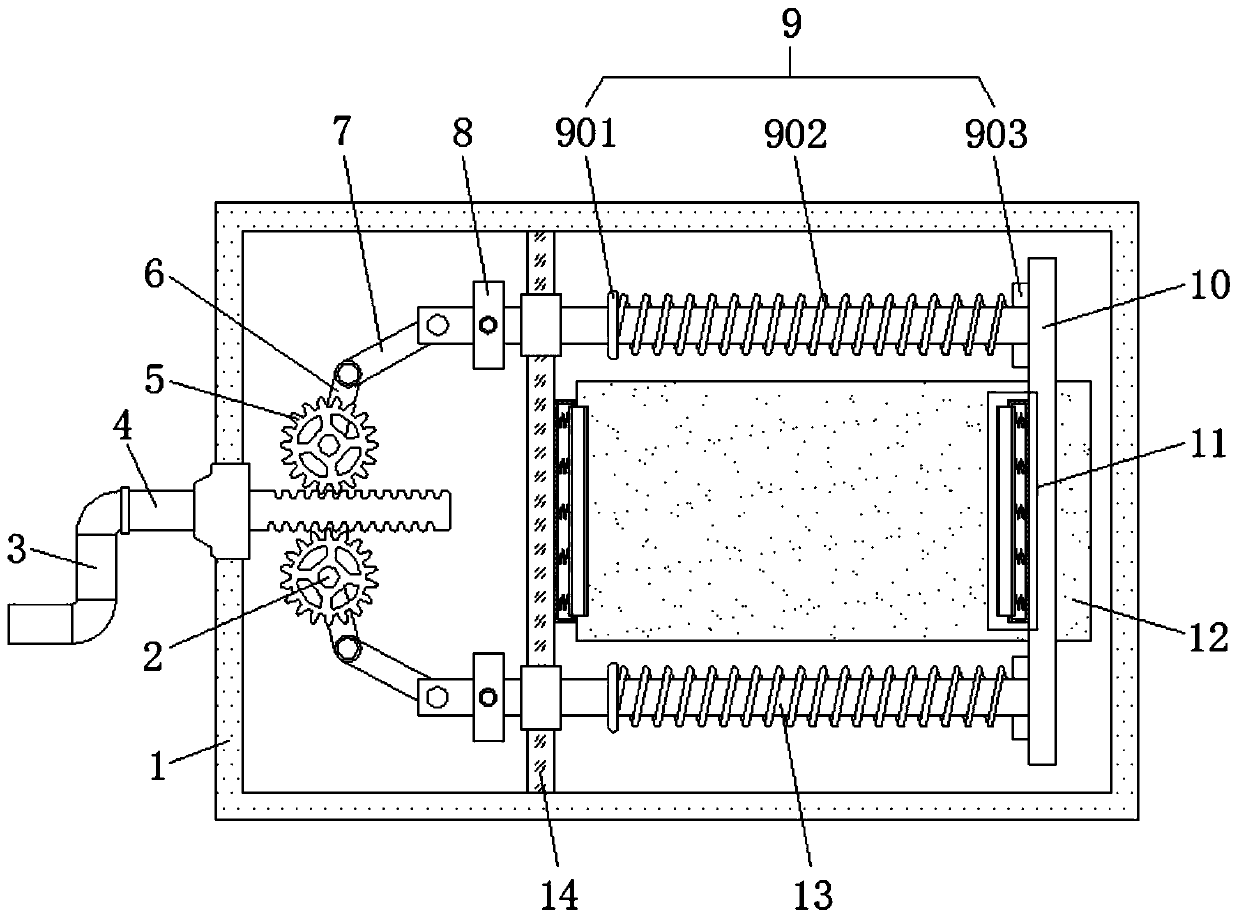

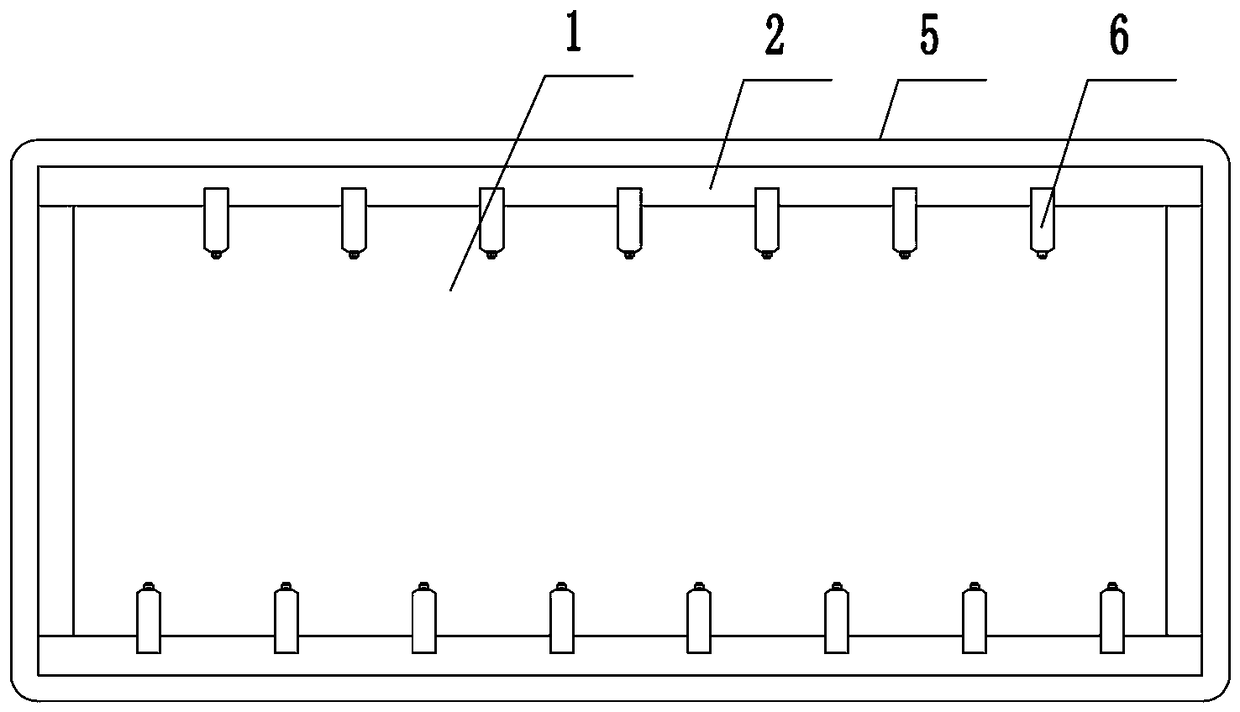

Anti-attenuation aging detection apparatus for luminescent materials

InactiveCN108519323AFully irradiatedImprove efficiencyWeather/light/corrosion resistanceUltrasound attenuationFixed frame

The invention belongs to the technical field of detection equipment for luminescent materials and particularly relates to an anti-attenuation aging detection apparatus for luminescent materials, whichincludes: a box body, a sample rotary bracket, and a rotary motor which controls the sample rotary bracket to rotate; two main light sources are respectively installed on two corners, in same diagonal line, in the box body; the sample rotary bracket includes a top board and a bottom board, between which a plurality of sample placing brackets are arranged; the sample rotary bracket includes a fixing frame and a moving board rotationally connected thereto; the fixing frame is provided with a heating plate and a wire wrapping post; a pulling rope is tied to the wire wrapping post; a sample trough is formed in each moving board and is provided with a spring and a projection therein; the box body is sleeved with a shading cover. The detection apparatus allows the to-be-tested sample to rotateand achieves adjustment of the to-be-tested sample in horizontal and vertical directions; the to-be-tested luminescent material can be irradiated in all directions, thus increasing use efficiency of the apparatus.

Owner:NANCHANG INST OF TECH

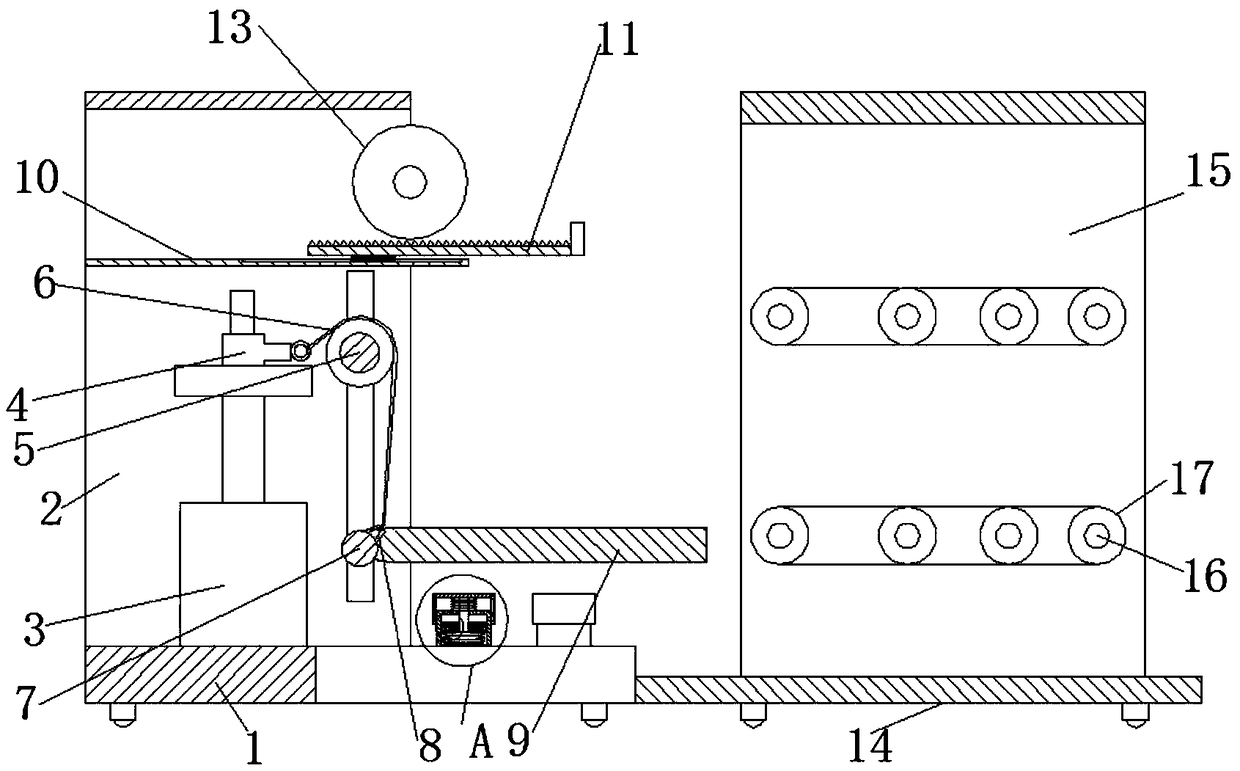

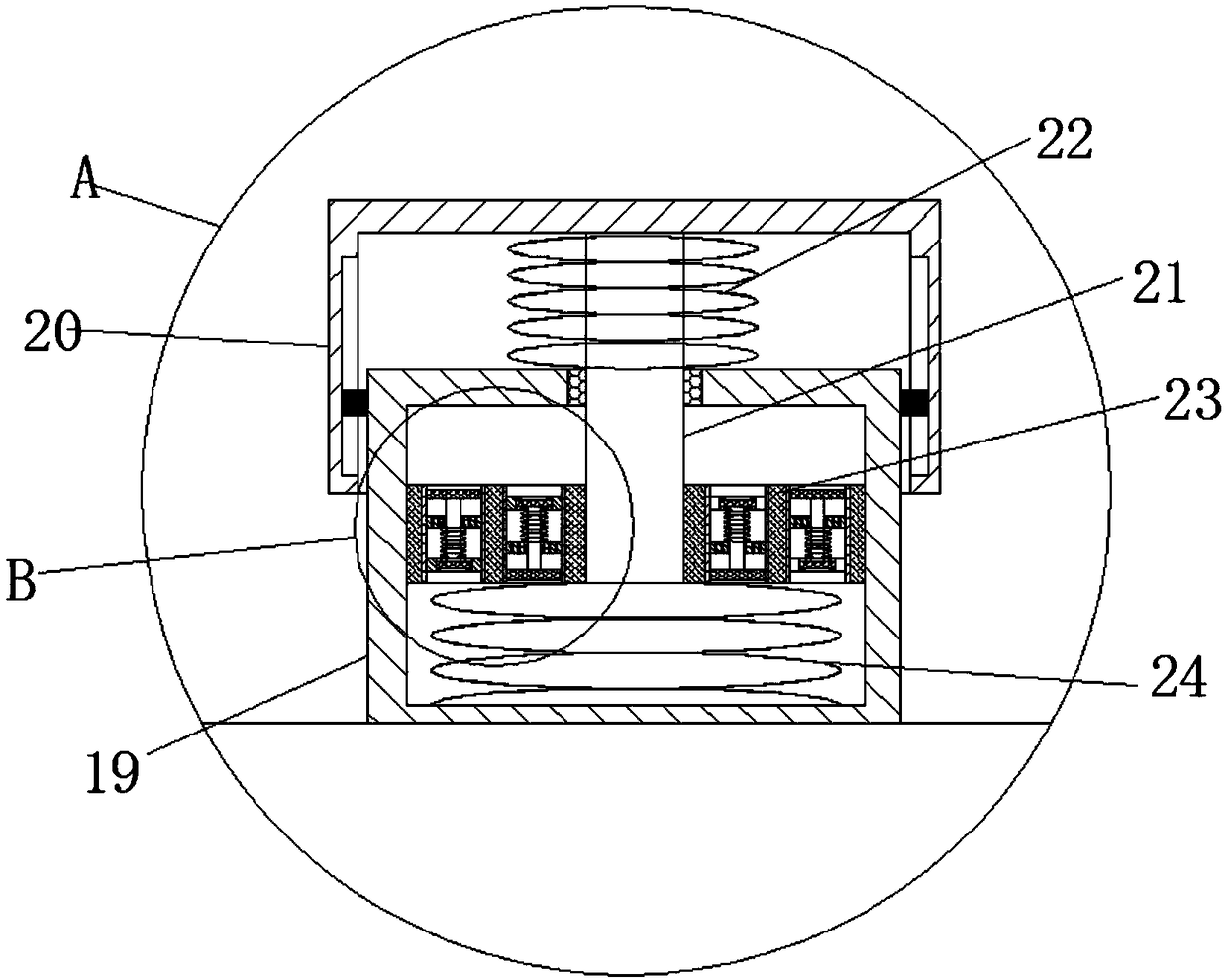

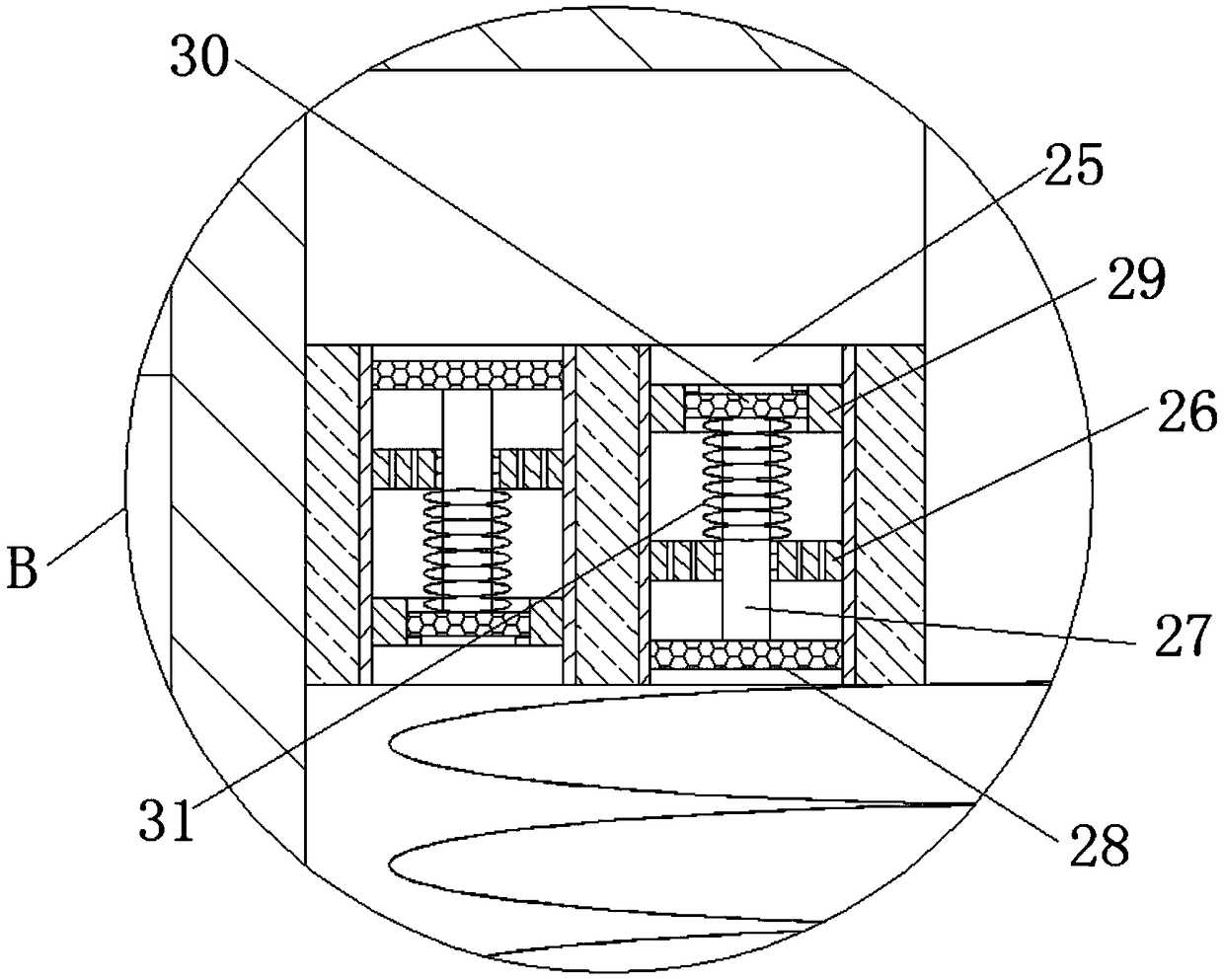

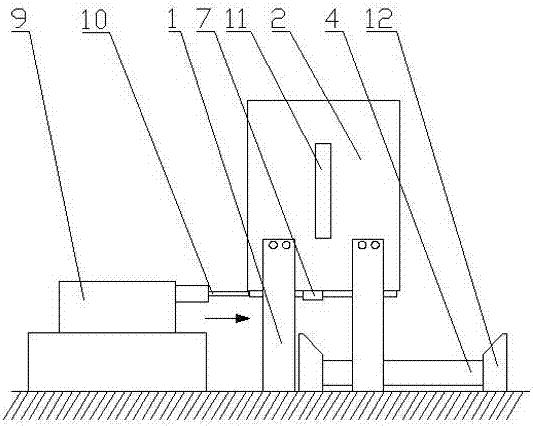

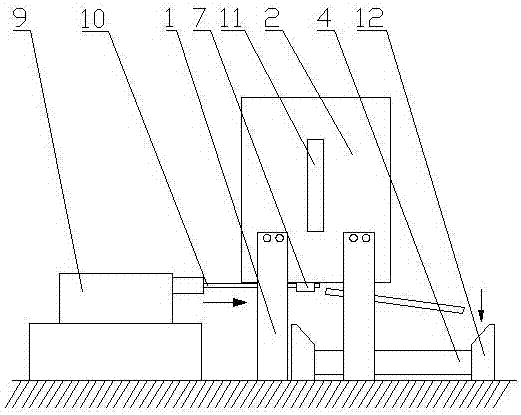

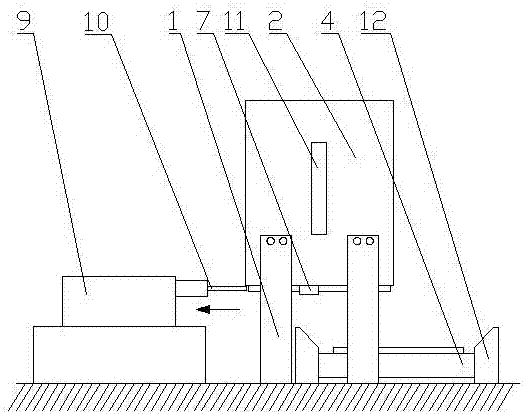

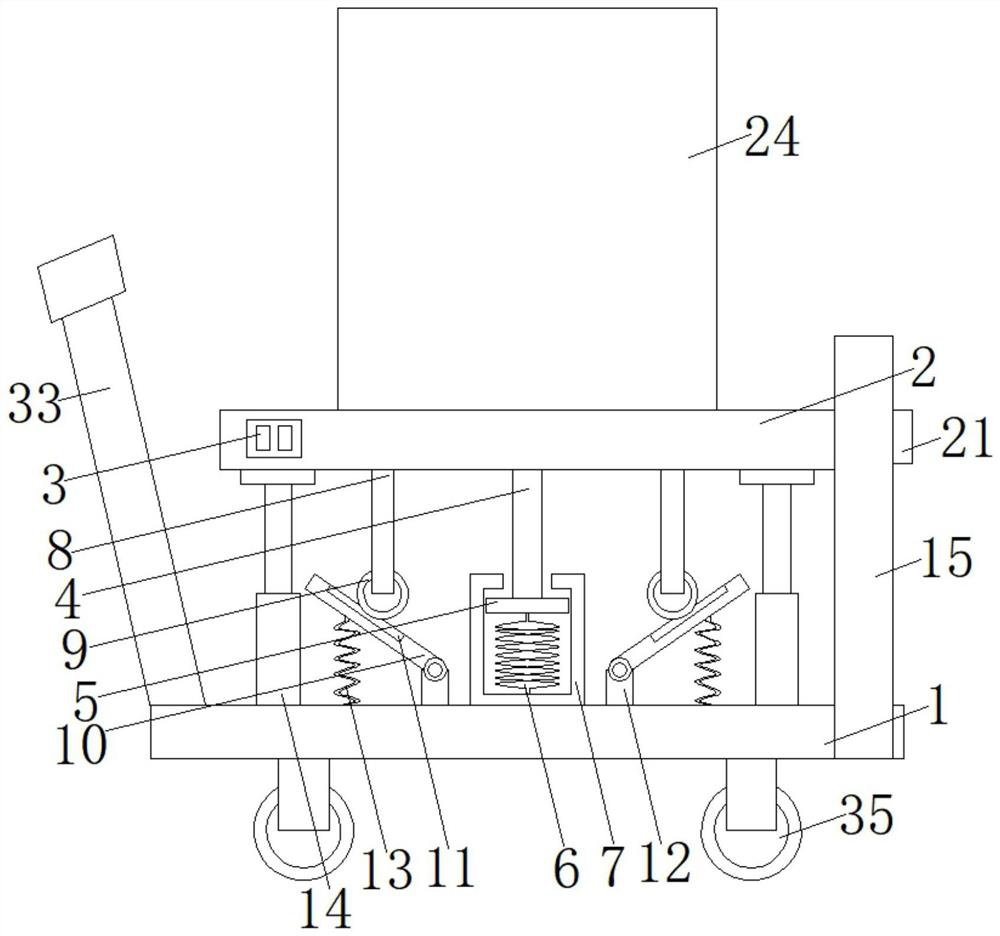

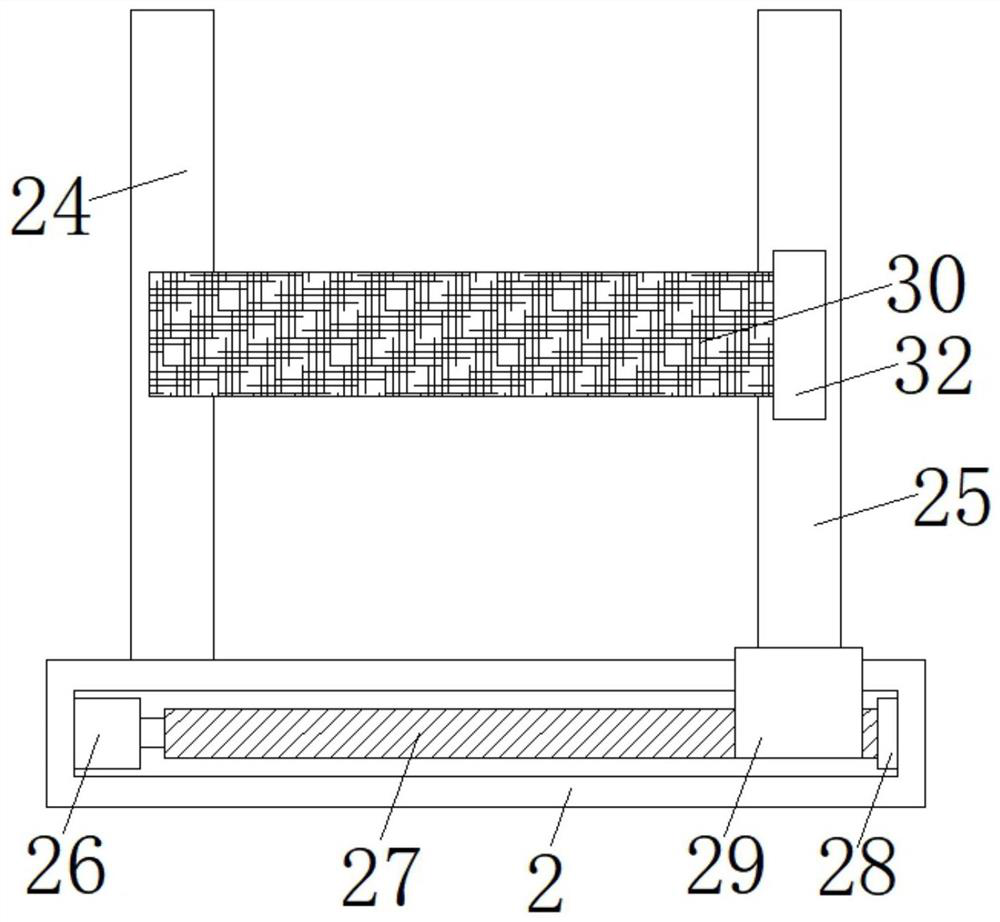

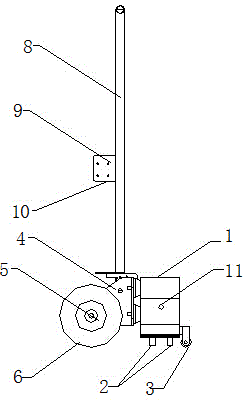

Novel pneumatic light lift

PendingCN108751007ASmall footprintSimple structureNon-rotating vibration suppressionLifting framesSprocketEngineering

The invention discloses a novel pneumatic light lift. The novel pneumatic light lift comprises a lifting mechanism and a conveying mechanism. The lifting mechanism comprises a chassis fixedly connected with the ground, the upper surface of the chassis is symmetrically and fixedly connected with two supporting plates, the upper surface of the chassis is fixedly connected with a linear air cylinder,an output shaft of the linear air cylinder is fixedly connected with a drive plate, the upper surface of the drive plate is fixedly connected with a first movable rod, the two ends of the first movable rod are slidingly connected with the two supporting plates, the rod walls of the first movable rod are symmetrically and fixedly sleeved with two chain wheels, the same second movable rod is slidingly connected between the two supporting plates, the rod walls of the second movable rod are symmetrically and fixedly sleeved with two fixing rings, and the same chain is wound between the chain wheels and the fixing rings jointly. Automatic loading and unloading can be achieved, the novel pneumatic light lift is small in occupied area, low in production cost and suitable for small workshops, andrigid damage to a lifting platform can be avoided.

Owner:ANHUI BOYI FLUID POWER TRANSMISSION

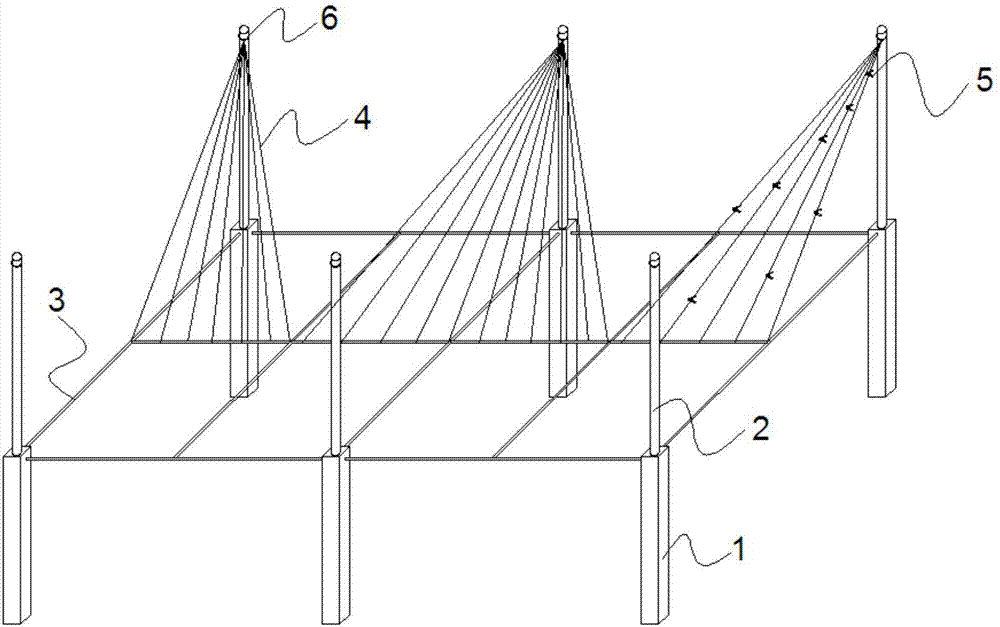

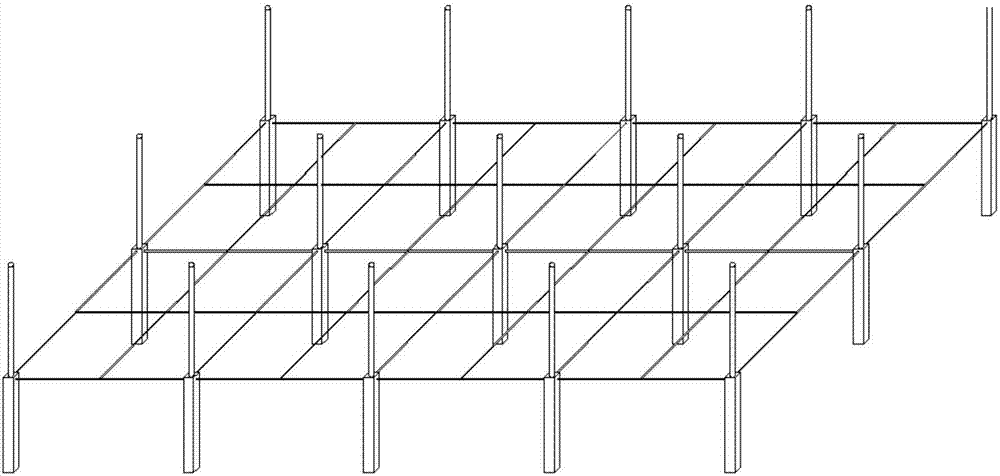

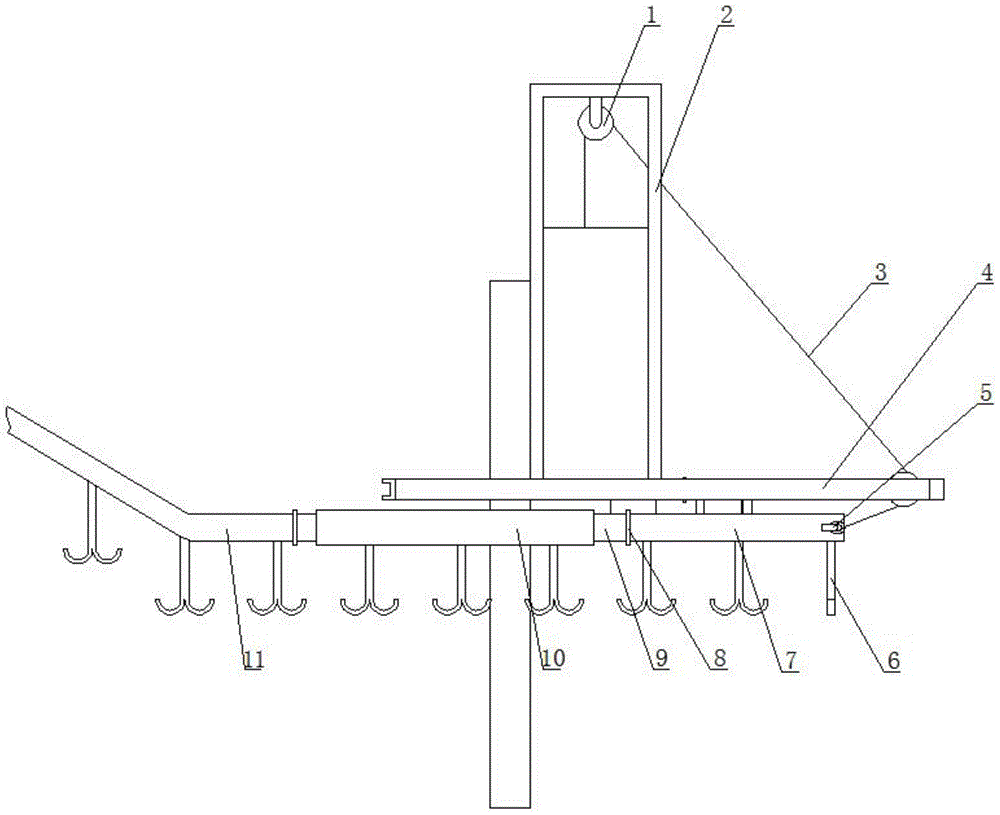

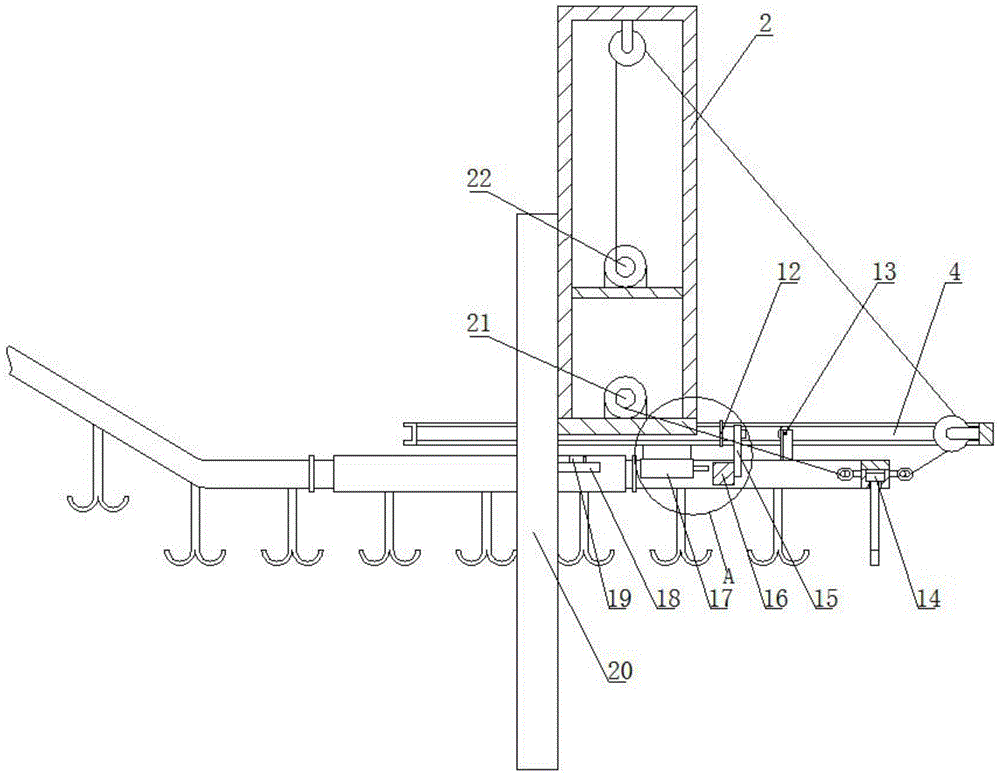

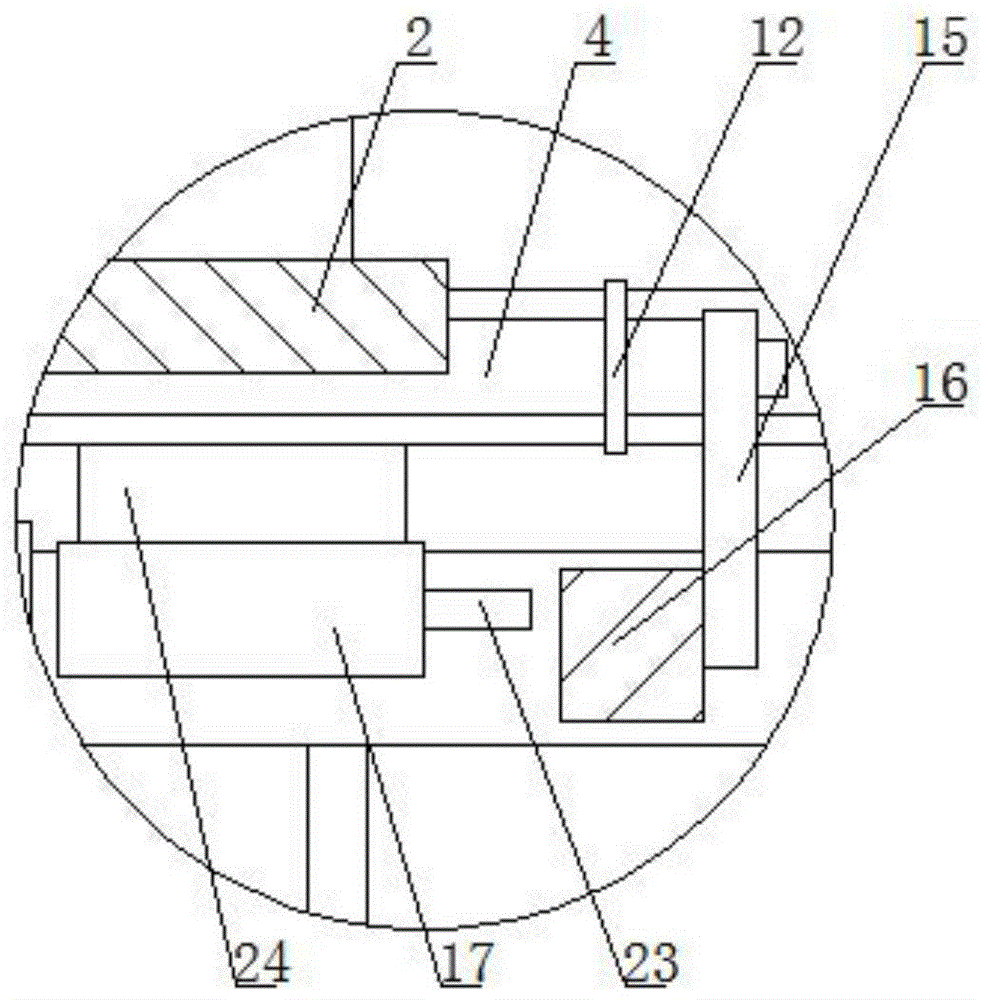

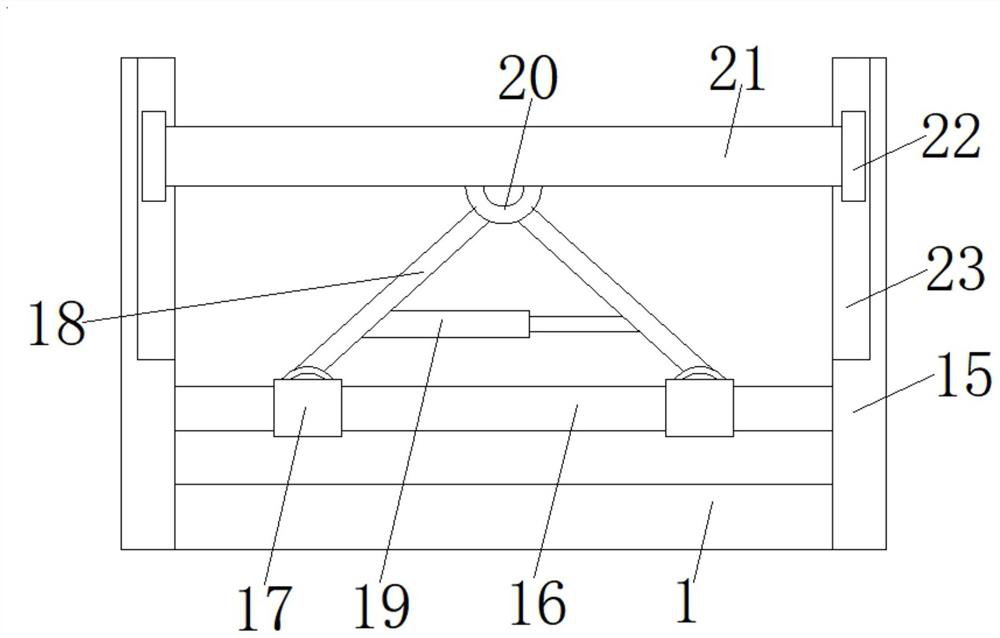

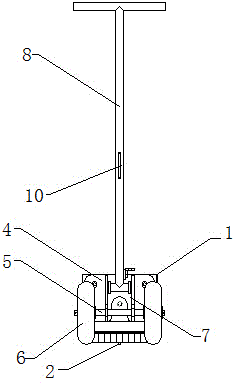

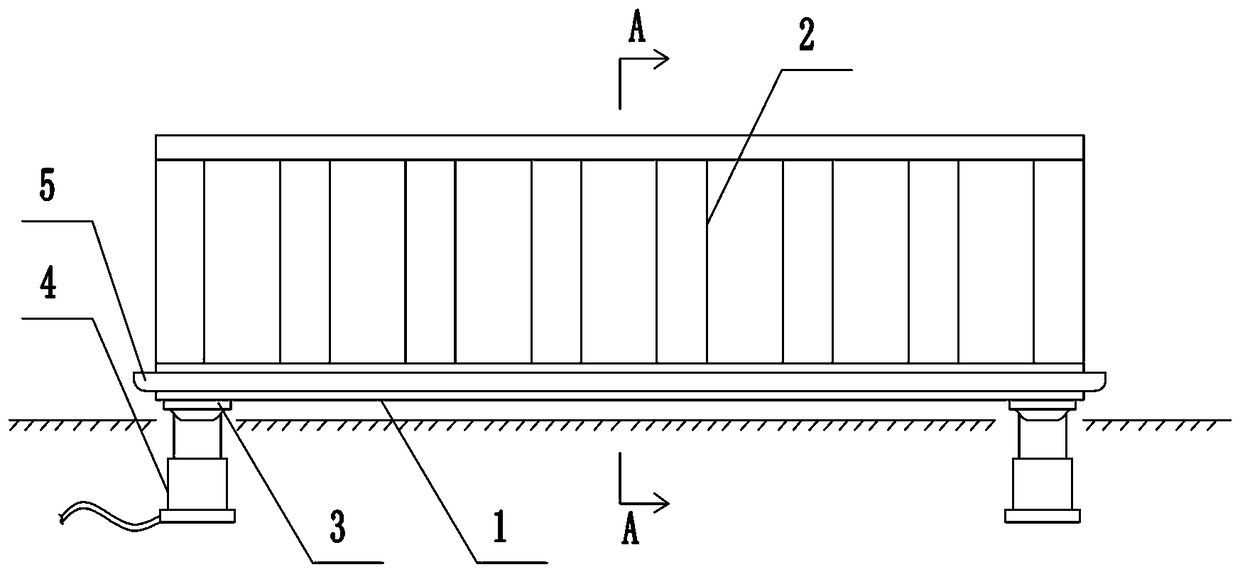

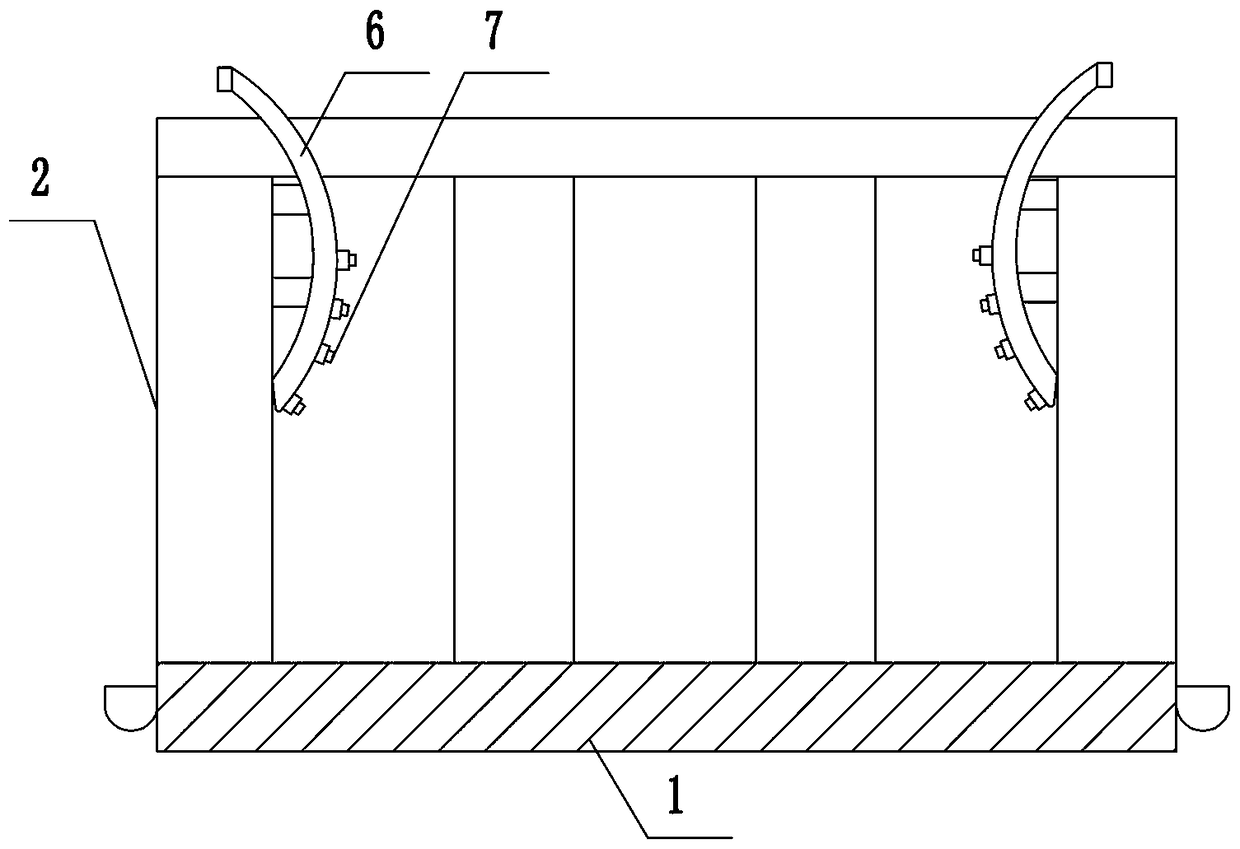

Planting frame for kiwifruit orchard

InactiveCN106954520APromote differentiationNutritiousCultivating equipmentsActinidiaGrowth management

The inventiondiscloses a planting frame for a kiwifruit orchard and belongs to the field of orchard planting. According to the planting frame, physiological growth and reproductive growth of kiwifruit branches can be effectively separated and protection management of fruits of the current year and healthy growth of fruits of the next year are facilitated. The planting frame comprises a plurality of support columns and support frames arranged between the adjacent support columns, wherein the support frames are in a grid type, vertical rods are arranged at the tops of the support columns, multiple drawing wires are arranged between each vertical rod and the adjacent support frame which is located on the same side with the vertical rod, and multiple fixing clamps are arranged on the drawing wires. The vertical rods are additionally arranged on the basic kiwifruit orchard support frames, the drawing wires are arranged on the vertical rods in the higher positions and the support frames in the lower positions, oblique planes facing the same direction are formed to provide growth management space for the branches fruiting in the next year, and blades of the branches fruiting in the next year on the oblique planes can protect fruits of the current year on the support frames.

Owner:四川南冈闲田农业科技有限公司

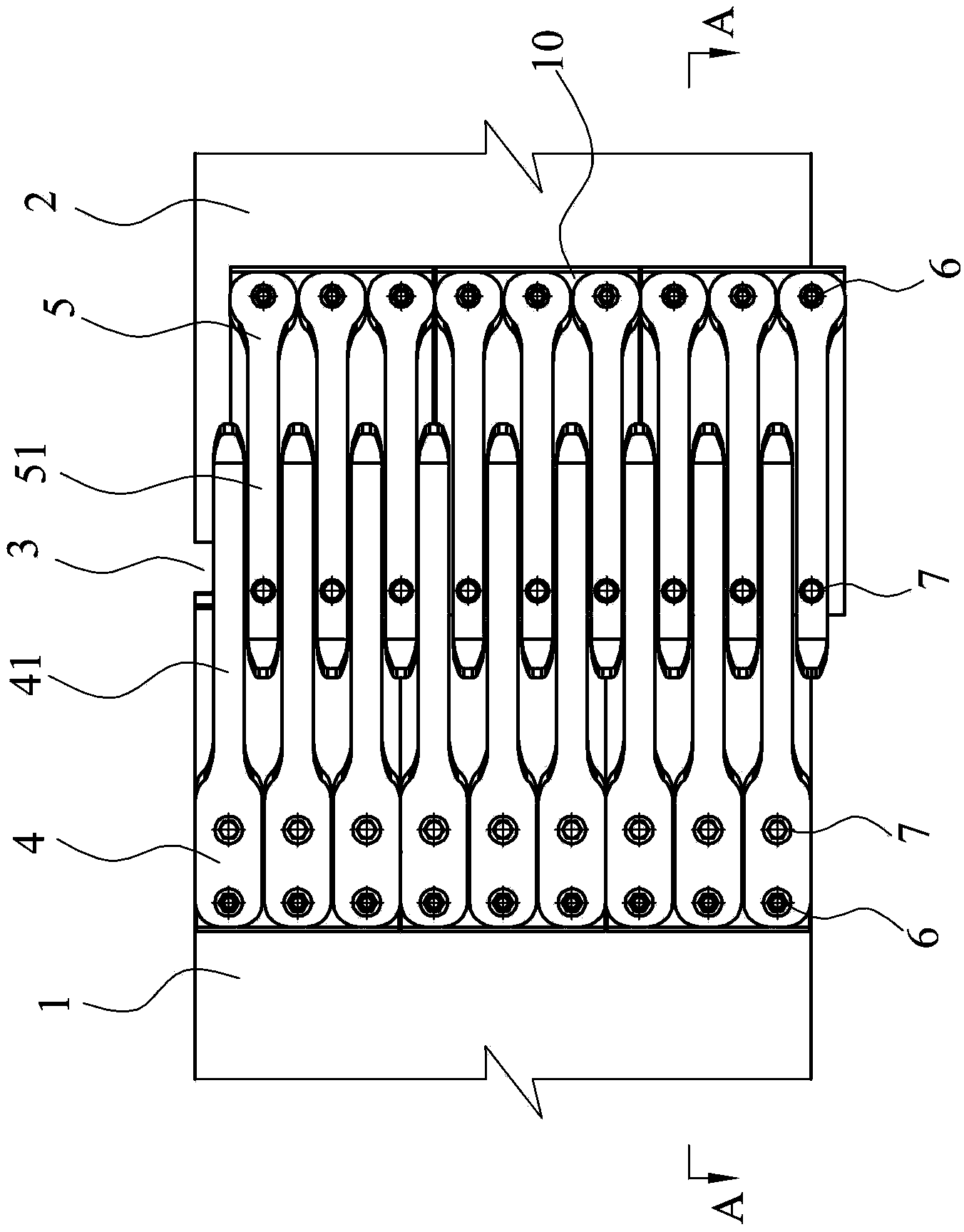

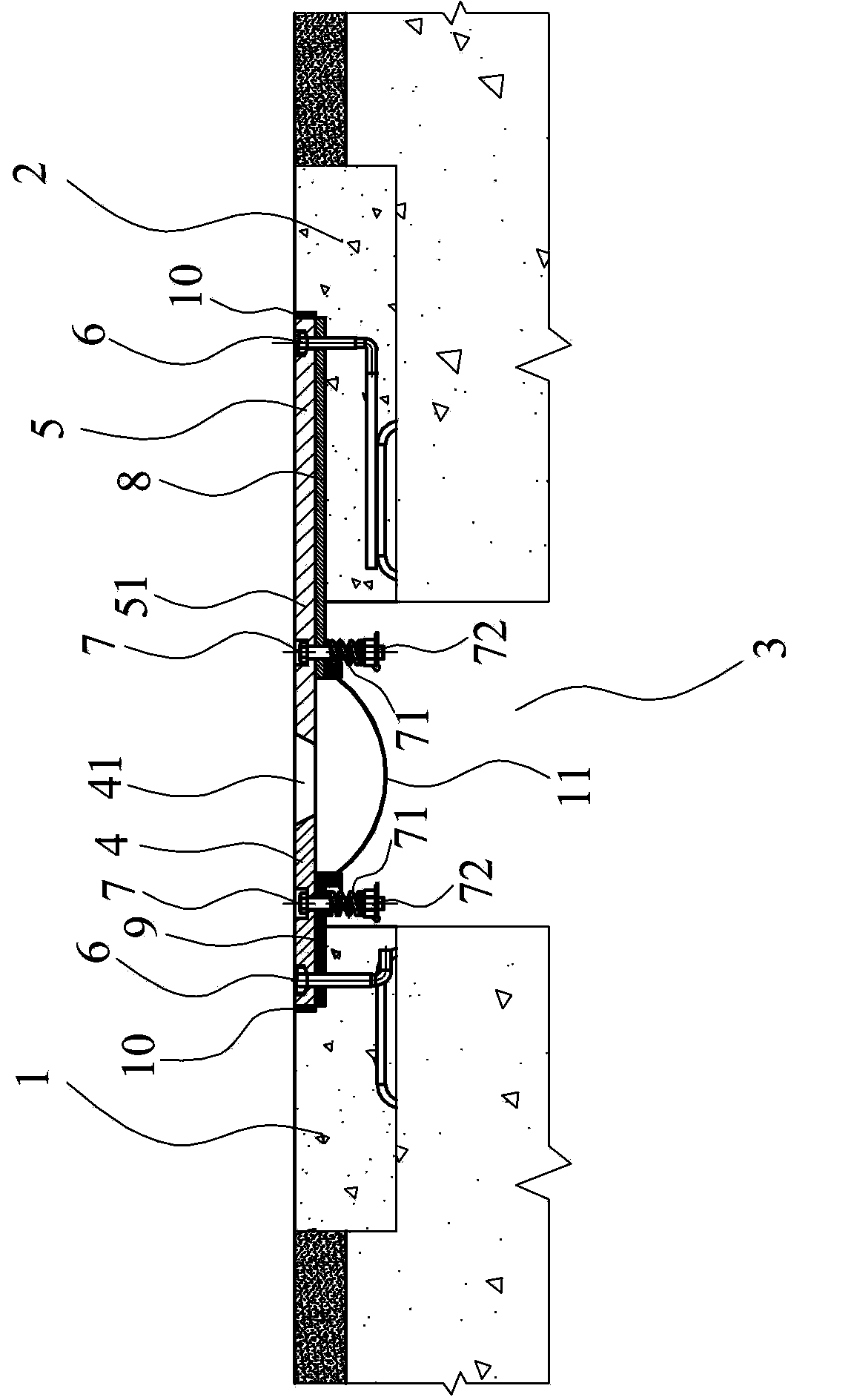

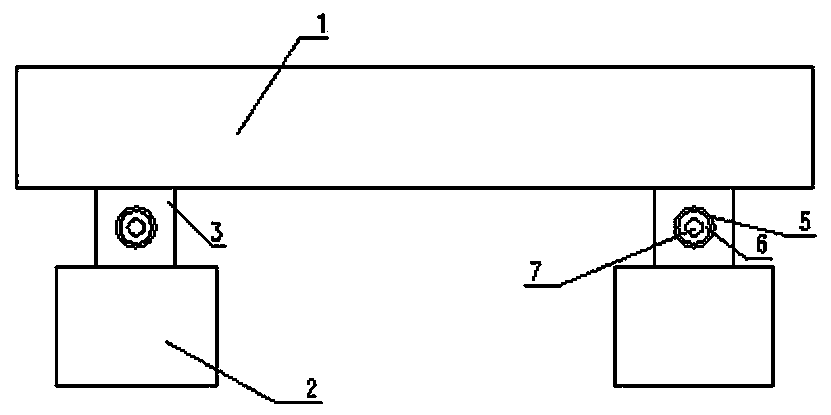

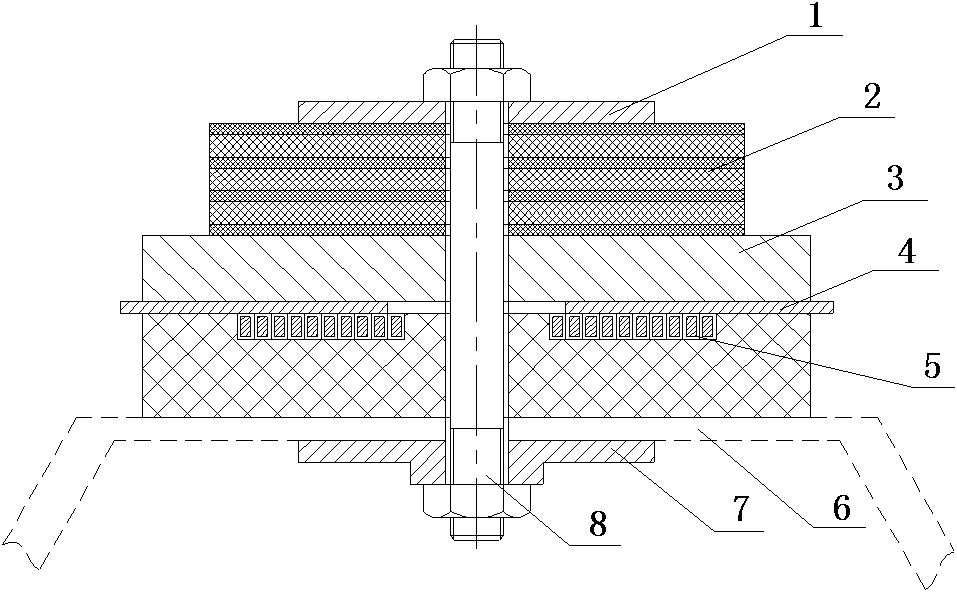

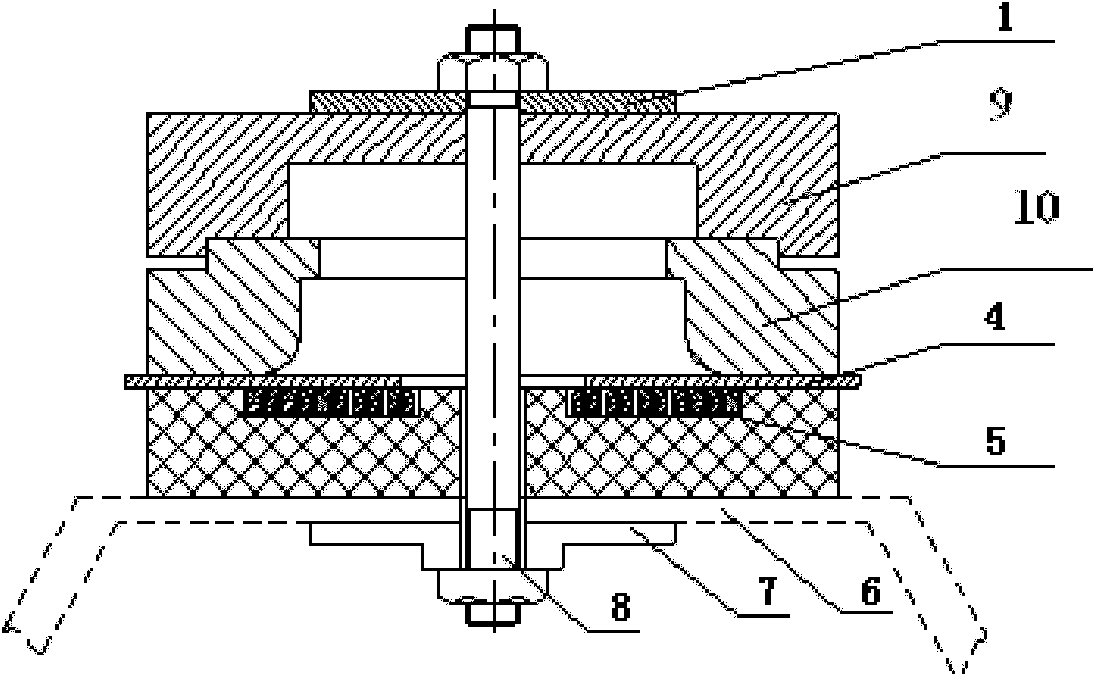

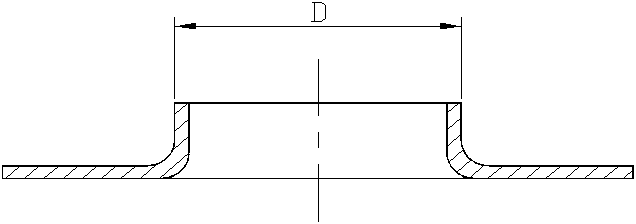

Bridge-rubber-pad limiting energy dissipation device

InactiveCN108824172AAvoid rigid damageInhibit sheddingBridge structural detailsEngineeringSteel tube

The invention discloses a bridge-rubber-pad limiting energy dissipation device. The bridge-rubber-pad limiting energy dissipation device is arranged between a bridge surface and a bridge pier; two rubber pads are symmetrically arranged on the bridge in the transverse direction of a bridge left and right, transverse pipes penetrate through the rubber pads along the centers of the side walls of therubber pads, protection caps are arranged in the centers of the side walls of the rubber pads, each protection pad is connected with a connection steel pipe, one ends of the two connection steel pipesare arranged in the transverse pipes, the other end of one connection steel pipe is connected with the bridge surface, the other end of the other connection steel pipe is connected with the bridge pier, the two connection steel pipes are arranged at pipe openings in the transverse pipes, and are each provided with a connection ball, and the two connection balls are each connected with an energy dissipation spring, and are connected through the energy dissipation springs. By means of the bridge-rubber-pad limiting energy dissipation device, rigidity damage between the bridge surface and the bridge pier can be avoided, and the falling phenomenon of the bridge surface is prevented.

Owner:SHENYANG JIANZHU UNIVERSITY

Life test method of magnetic-pulse forming inductor

The invention, which belongs to the magnetic pulse forming technology field, particularly relates to a life test method of a magnetic-pulse forming inductor. A locating block and a die in a magnetic-pulse forming inductor life actual test apparatus are respectively replaced by a rubber gasket and a supporting plate, so that a magnetic-pulse forming inductor life equivalent test apparatus is formed. According to the method provided in the invention, the service life of the inductor can be simply and conveniently detected with low cost.

Owner:CAPITAL AEROSPACE MACHINERY

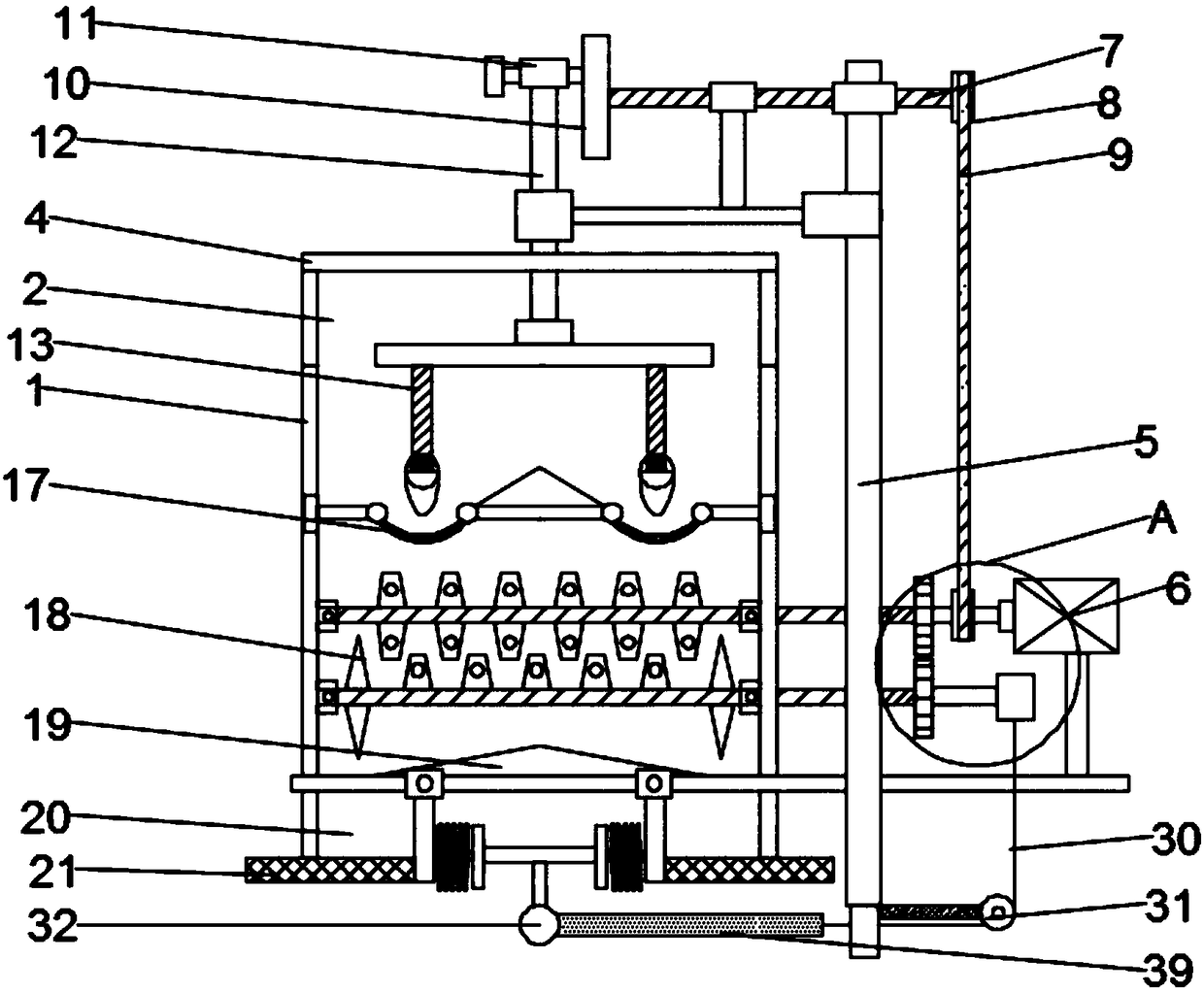

Waste residue crushing device for cement production

InactiveCN108970685AAvoid rigid damageThoroughly crushed and crushedGrain treatmentsEnergy conservationWaste management

The invention discloses a waste residue crushing device for cement production. The waste residue crushing device comprises a machine body, a crushing cavity, a feeding opening, an upper cover plate, mashing assemblies, a crushing assembly and discharge openings, wherein a supporting vertical plate is vertically arranged on the right side of the machine body; the crushing cavity is formed inside the machine body; the upper cover plate is fixedly welded to the upper part of the machine body; the feeding opening is formed in the rear side of the upper surface of the upper cover plate and is communicated with the crushing cavity; two mashing assemblies are symmetrically arranged at the top in the crushing cavity; the crushing cavity is characterized in that the crushing assembly is arranged below the mashing assemblies,; the crushing assembly comprises first crushing blades and second crushing blades; a guide plate is arranged at the middle position of the bottom of the crushing cavity; two discharge openings are symmetrically formed in the bottom of the crushing cavity. The waste residue crushing device disclosed by the invention can ensure full mashing and crushing treatment of reutilized waste residues and achieves energy conservation and environmental protection, so that solid wastes can be recycled while the effect of treating solid waste is realized.

Owner:奚永乐

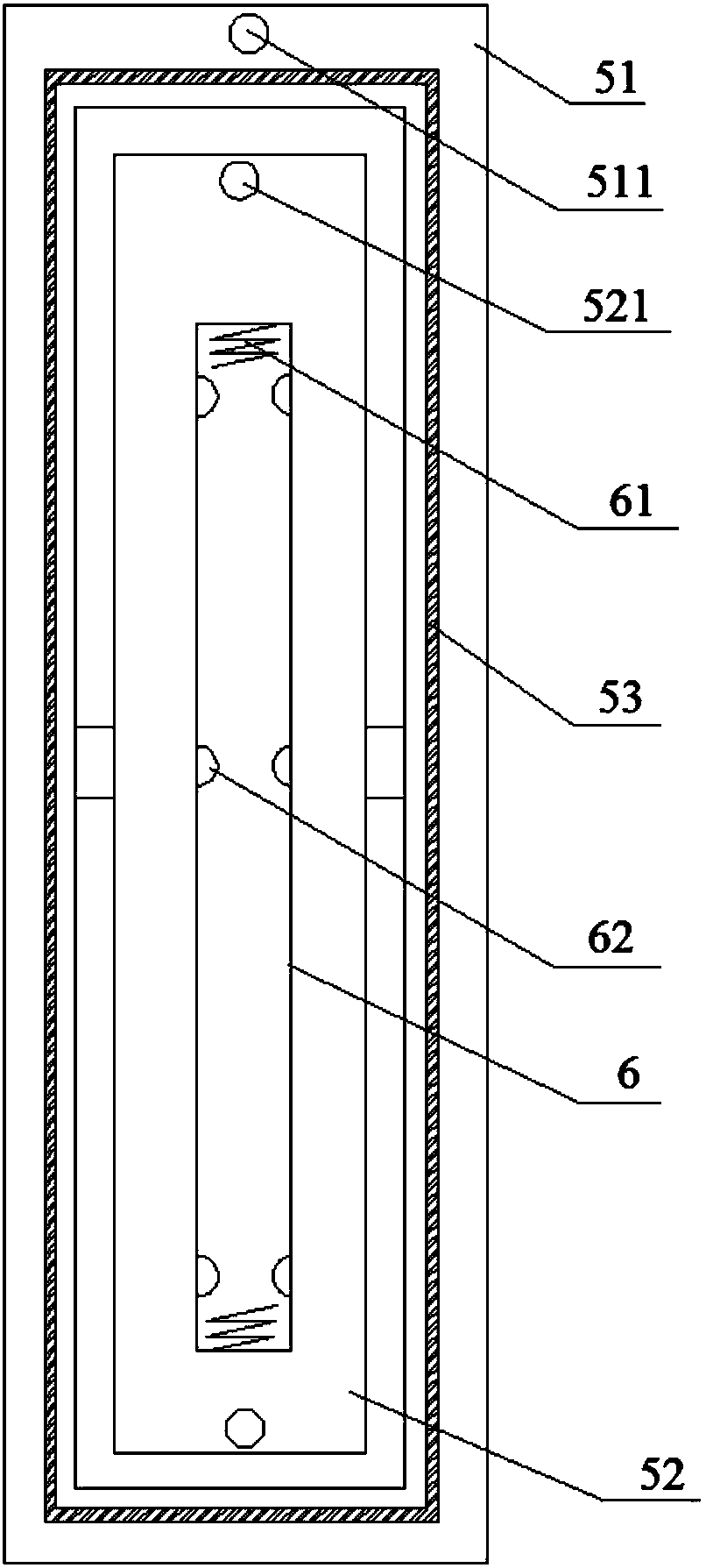

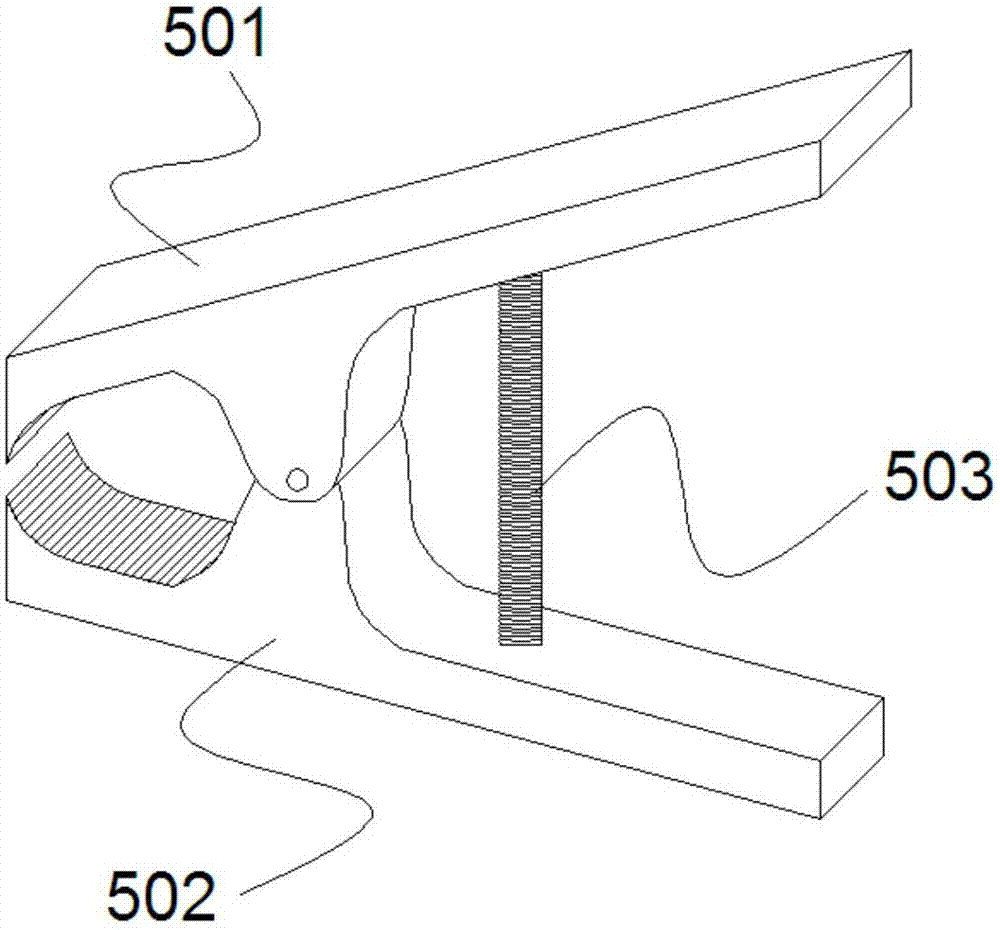

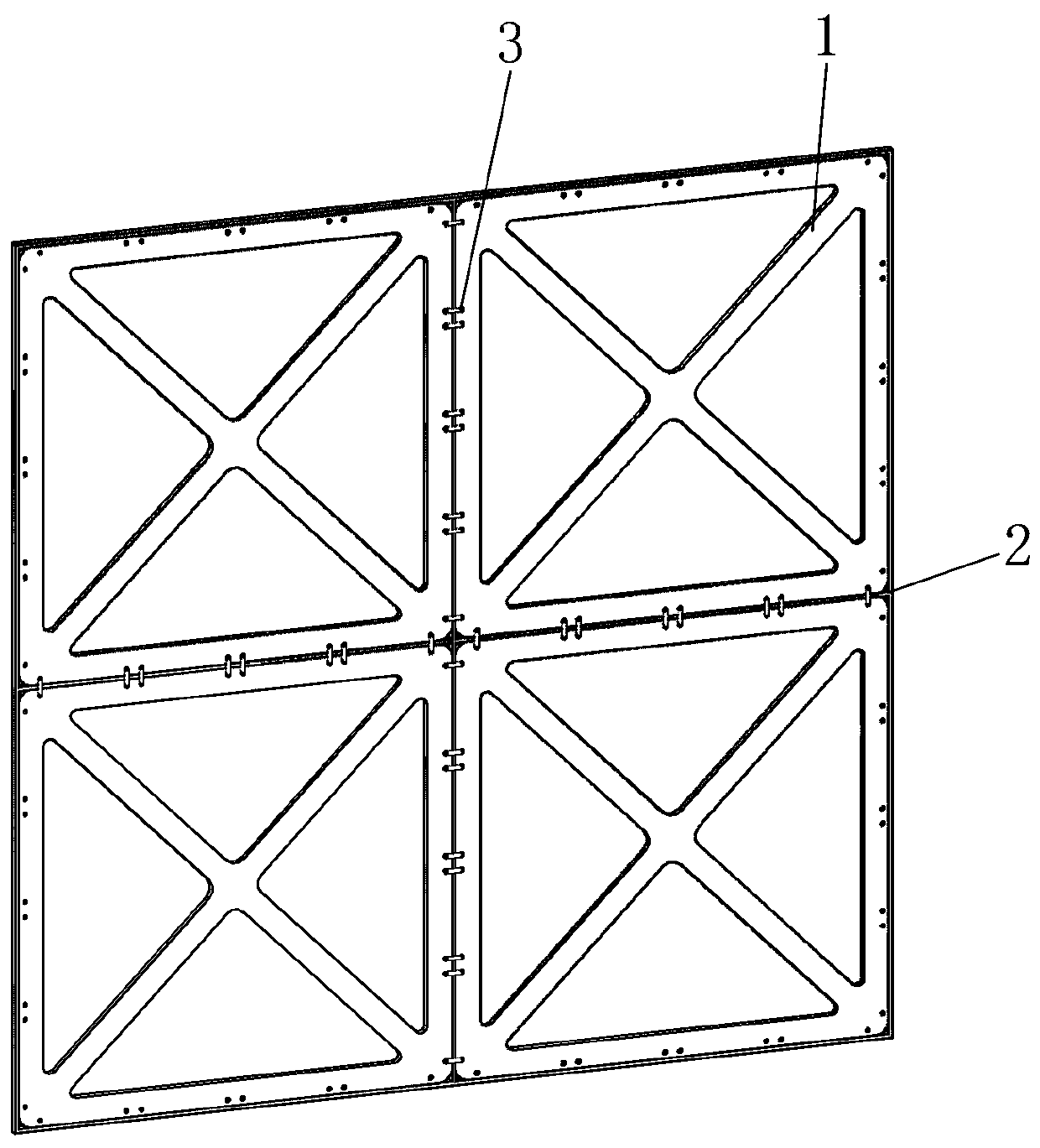

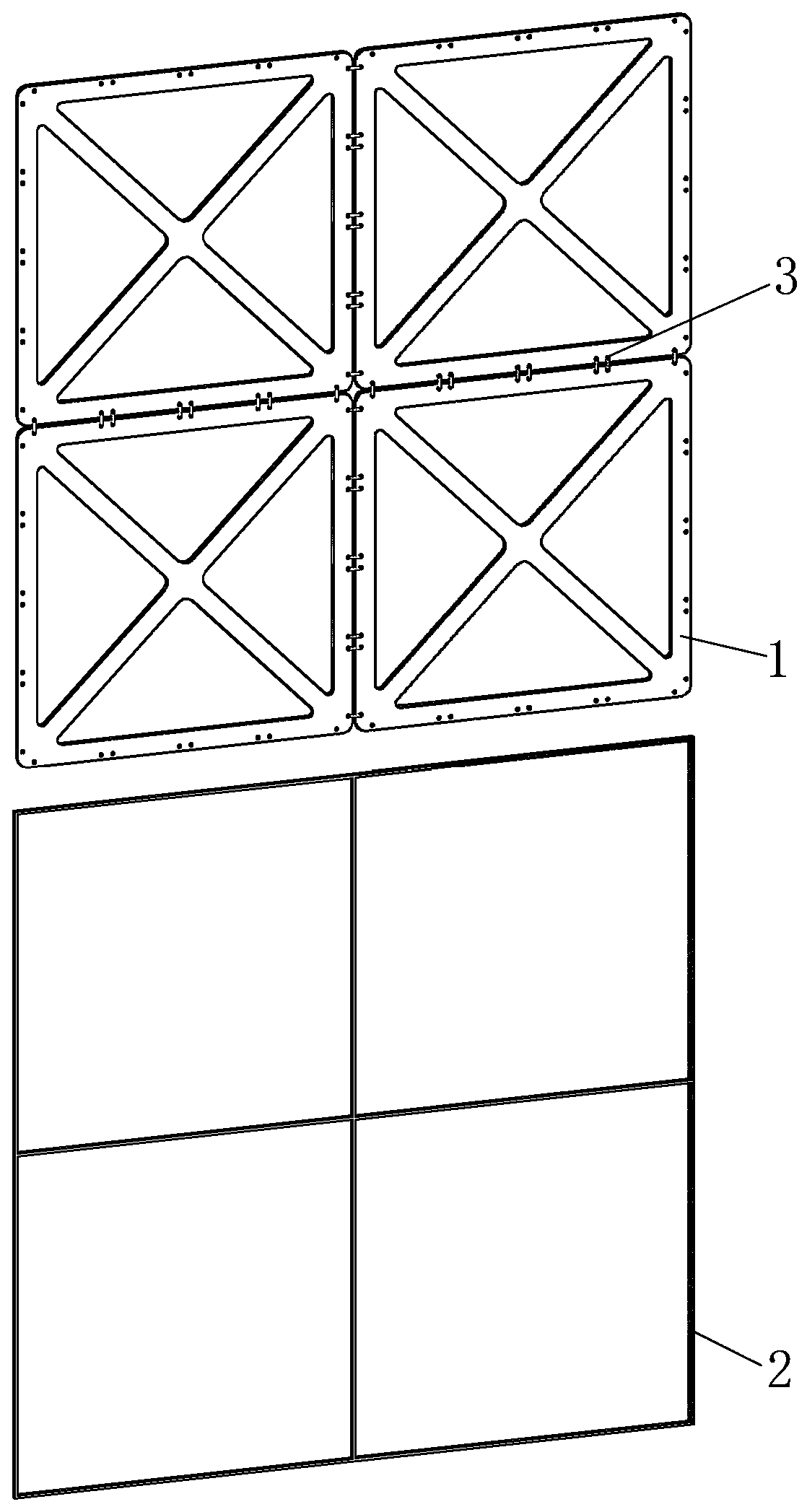

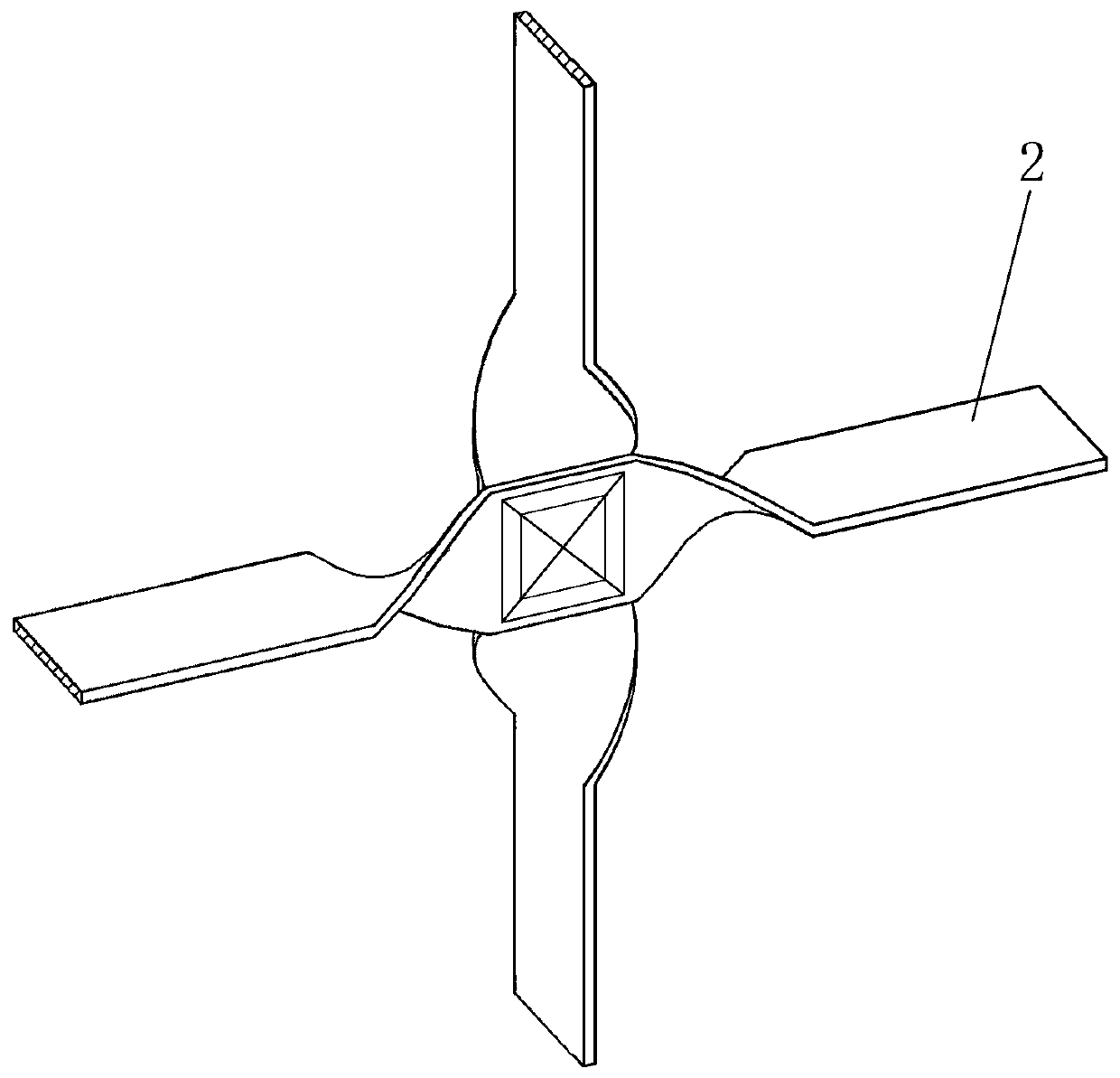

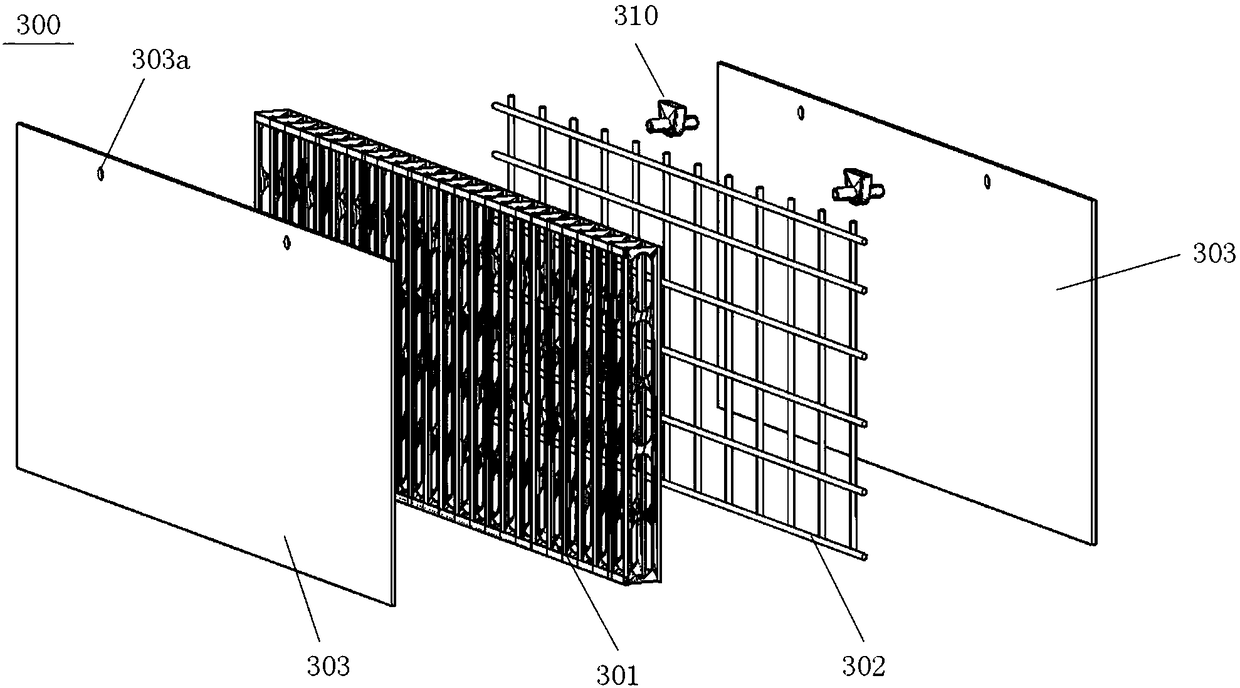

Modularized flexible-connection large-area supporting framework

ActiveCN109672401AControl flatnessSimple connection structurePhotovoltaicsSolar panel attachmentsFiberAluminum honeycomb

The invention discloses a modularized flexible-connection large-area supporting framework, belongs to the technical field of large-area supporting and aims at solving the problem that an existing rigid solar cell array cannot be applied to a stratospheric airship in a large-area mode. The modularized flexible-connection large-area supporting framework comprises module units, a flexible binding netand connection ropes, wherein each module unit is composed of two layers of carbon fiber plates and one layer of aluminum honeycomb plate, the aluminum honeycomb plate is clamped between the two layers of carbon fiber plates, and the two layers of carbon fiber plates are both bonded with the aluminum honeycomb plate; the flexible binding net is composed of rope belts which are distributed in a criss-cross mode, cross parts are connected in a stitching mode, one module unit is arranged in each grid, the adjacent module units are in binding connection through the connection ropes, and a rope passing hole corresponding to the connection rope is arranged on each module unit; a same size or a slightly smaller size of solar panel can be arranged on each module unit, and the solar panels can beconnected to the module units through the connection ropes. The modularized flexible-connection large-area supporting framework disclosed by the invention is used for supporting large-area solar cellarrays.

Owner:HARBIN INST OF TECH

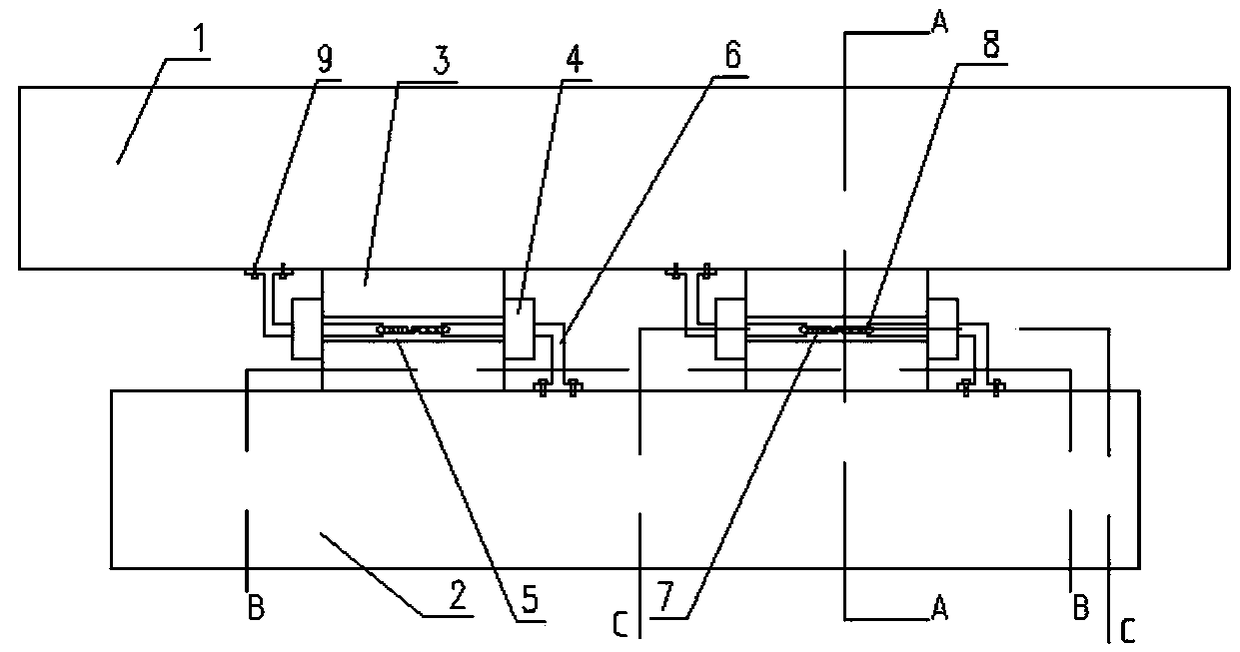

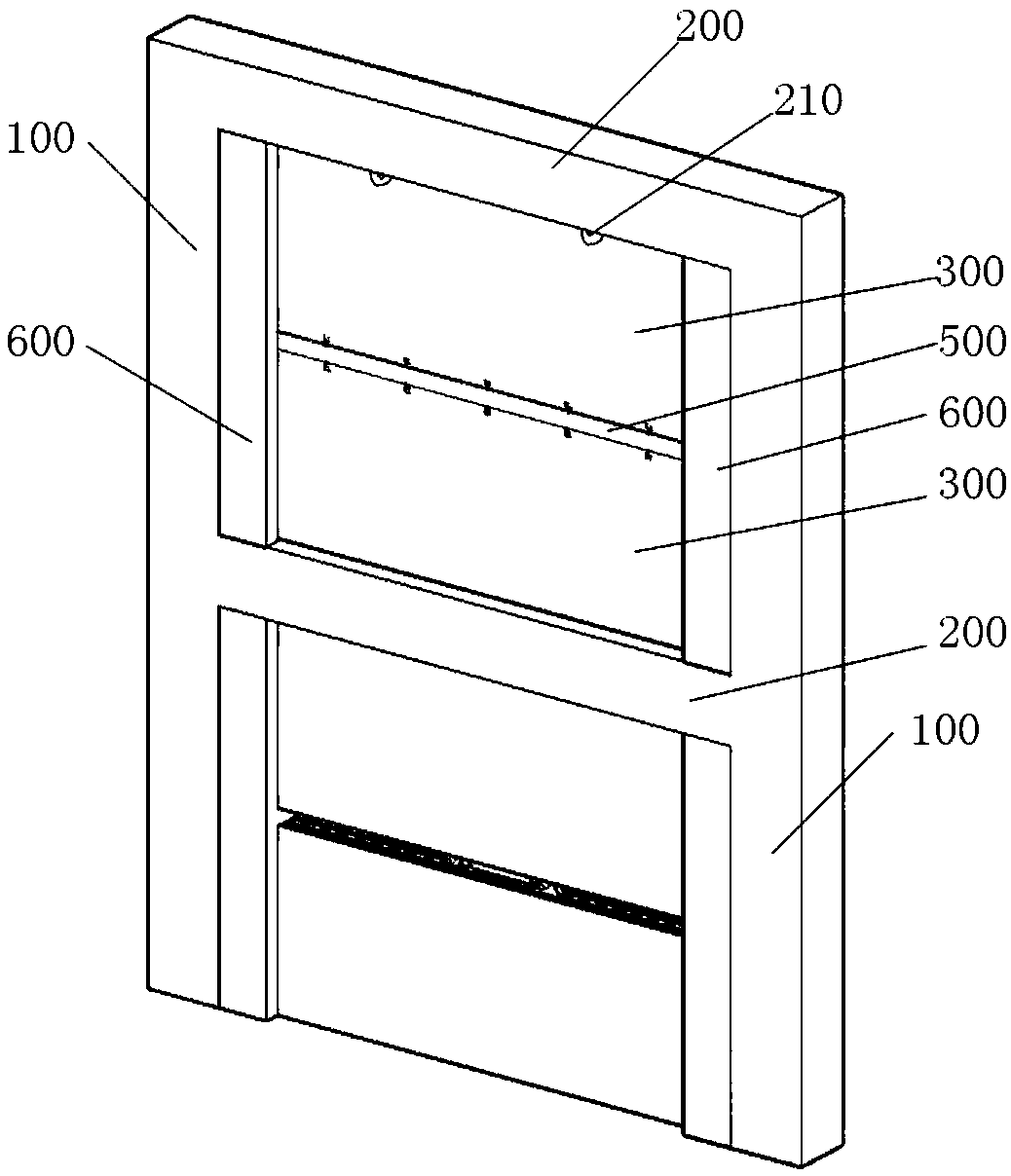

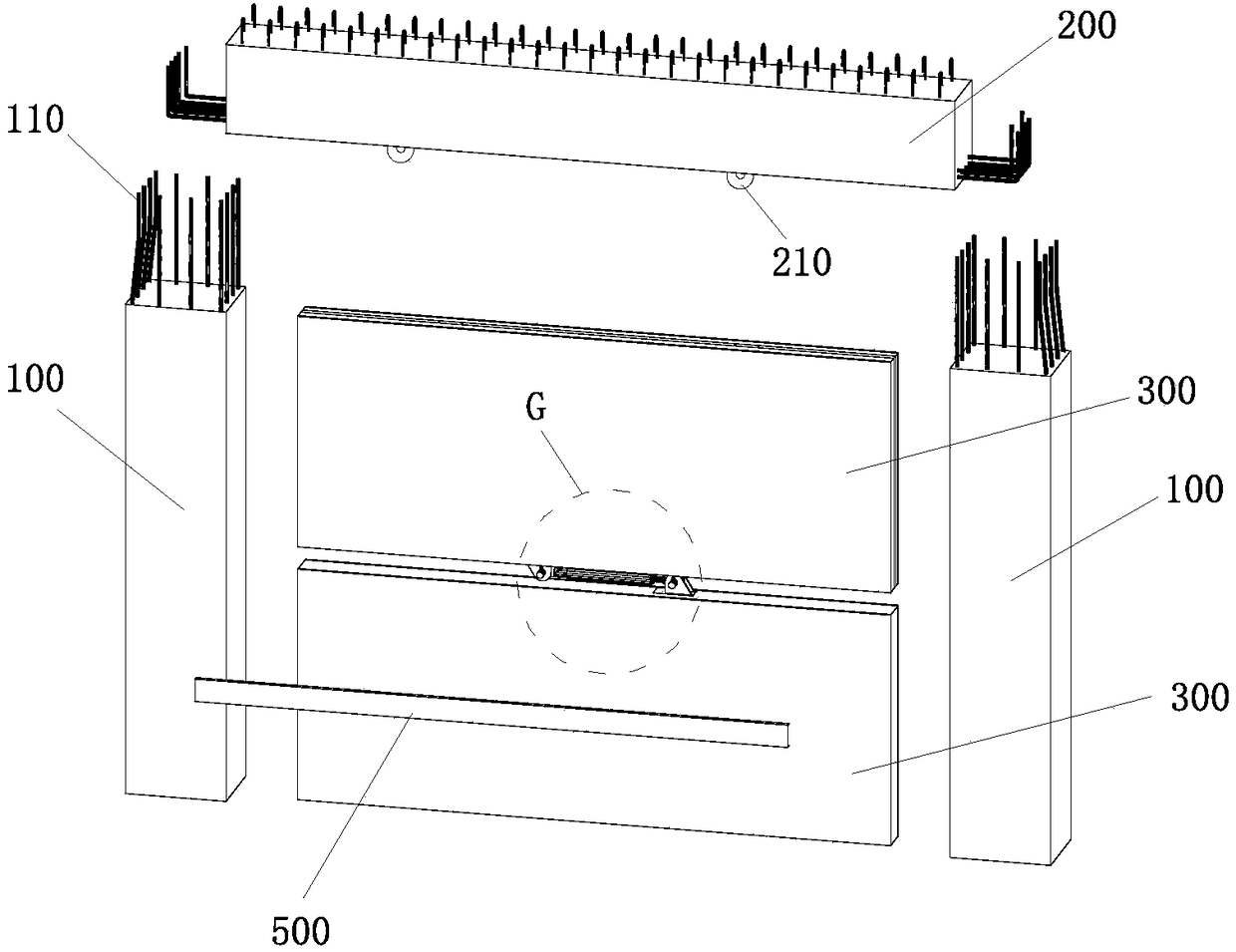

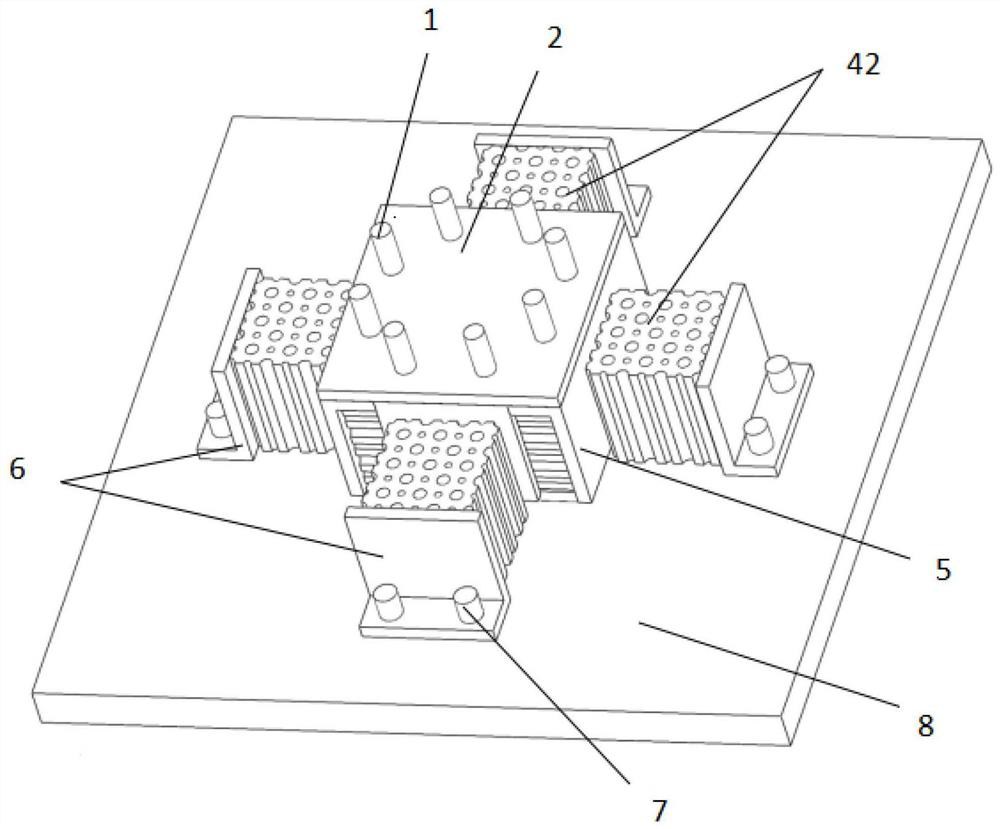

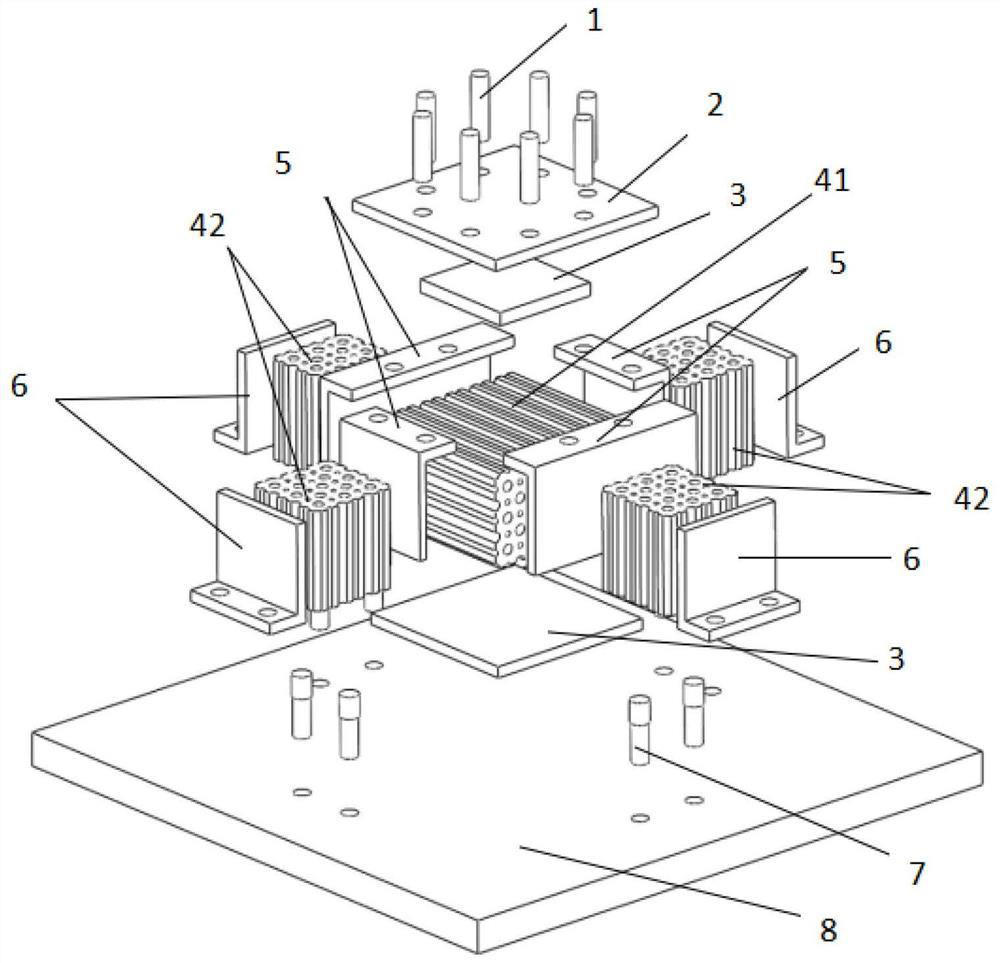

Assembled integral type energy-consuming framework wallboard system and construction method

ActiveCN108240053ADoes not hinder horizontal vibrationAvoid rigid damageWallsProtective buildings/sheltersEngineeringEngineering structures

The invention belongs to the field of civil engineering structure, and particularly relates to an assembled integral type energy-consuming framework wallboard system and a construction method. The energy-consuming framework wallboard system comprises precast columns, precast beams, energy-consuming wallboards, viscous dampers and cover plates, wherein the precast columns and the precast beams forman assembled integral type framework, the energy-consuming wallboards are fixed on the precast beams, and adjacent energy-consuming wallboards are spliced together by the viscous dampers and the cover plates. In earthquake, the energy-consuming wallboards have a horizontal shaking space, energy dissipation is realized by utilizing damping force provided by the viscous dampers, so as to reduce vibration response of the structure, and avoid too early damage of the structure in the action of the earthquake, and therefore, a better earthquake prevention and disaster reduction capacity is achieved. In addition, the construction method is reasonable in procedure, convenient to operate, and convenient to popularize, and an assembled integral type energy-consuming framework wallboard system withfirm structure and excellent earthquake prevention and disaster reduction effect can be formed.

Owner:SHANGHAI CONSTR NO 5 GRP CO LTD

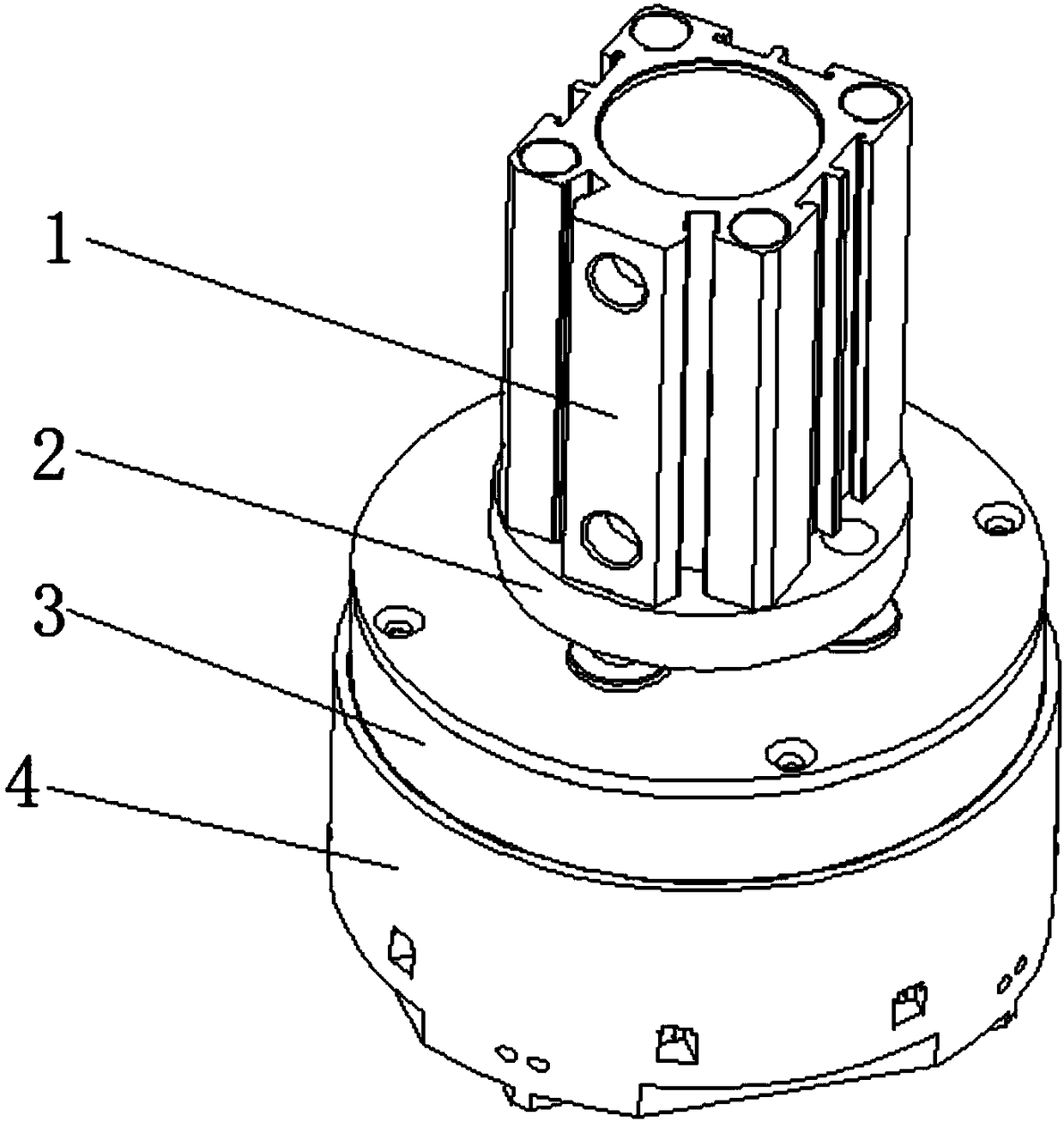

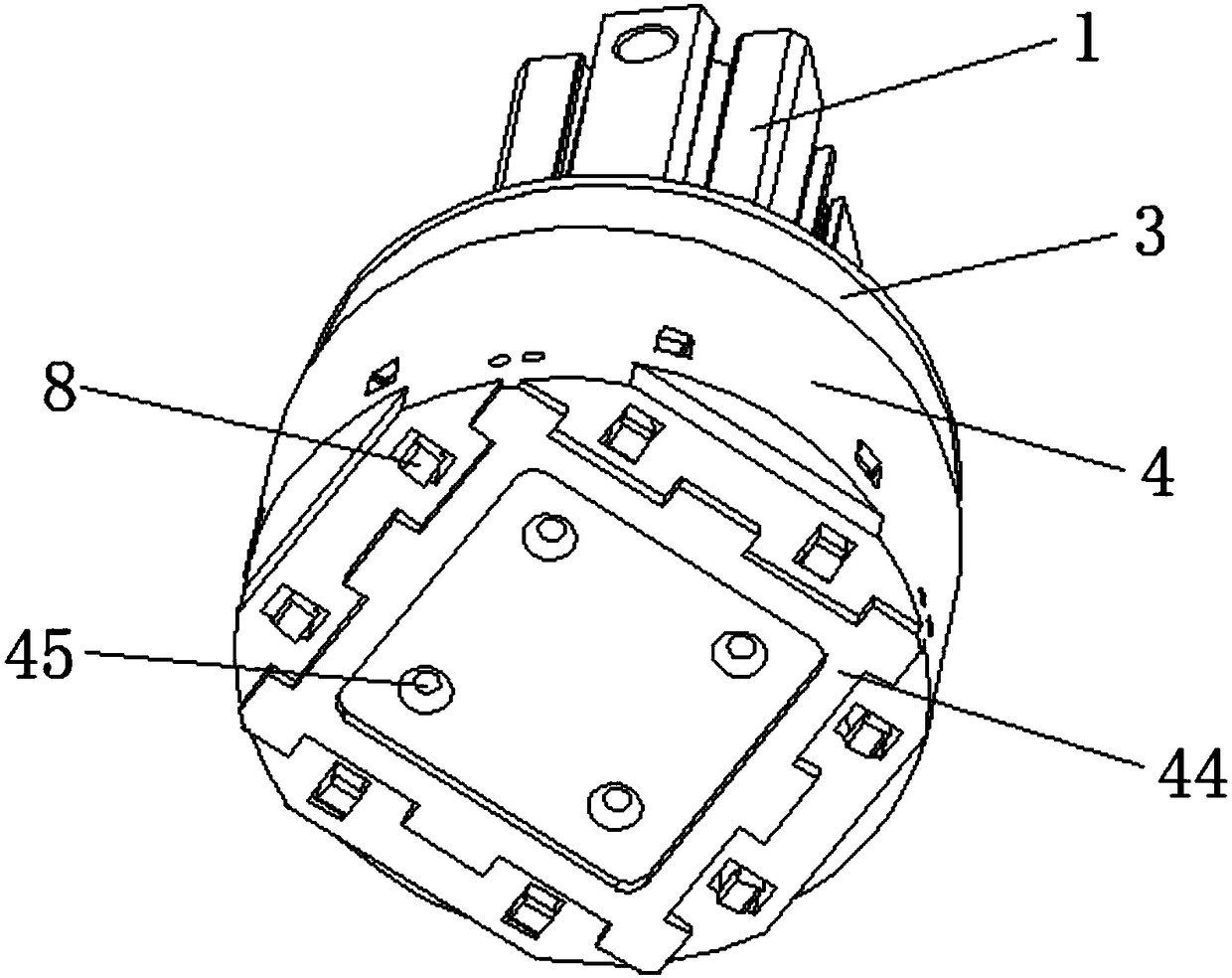

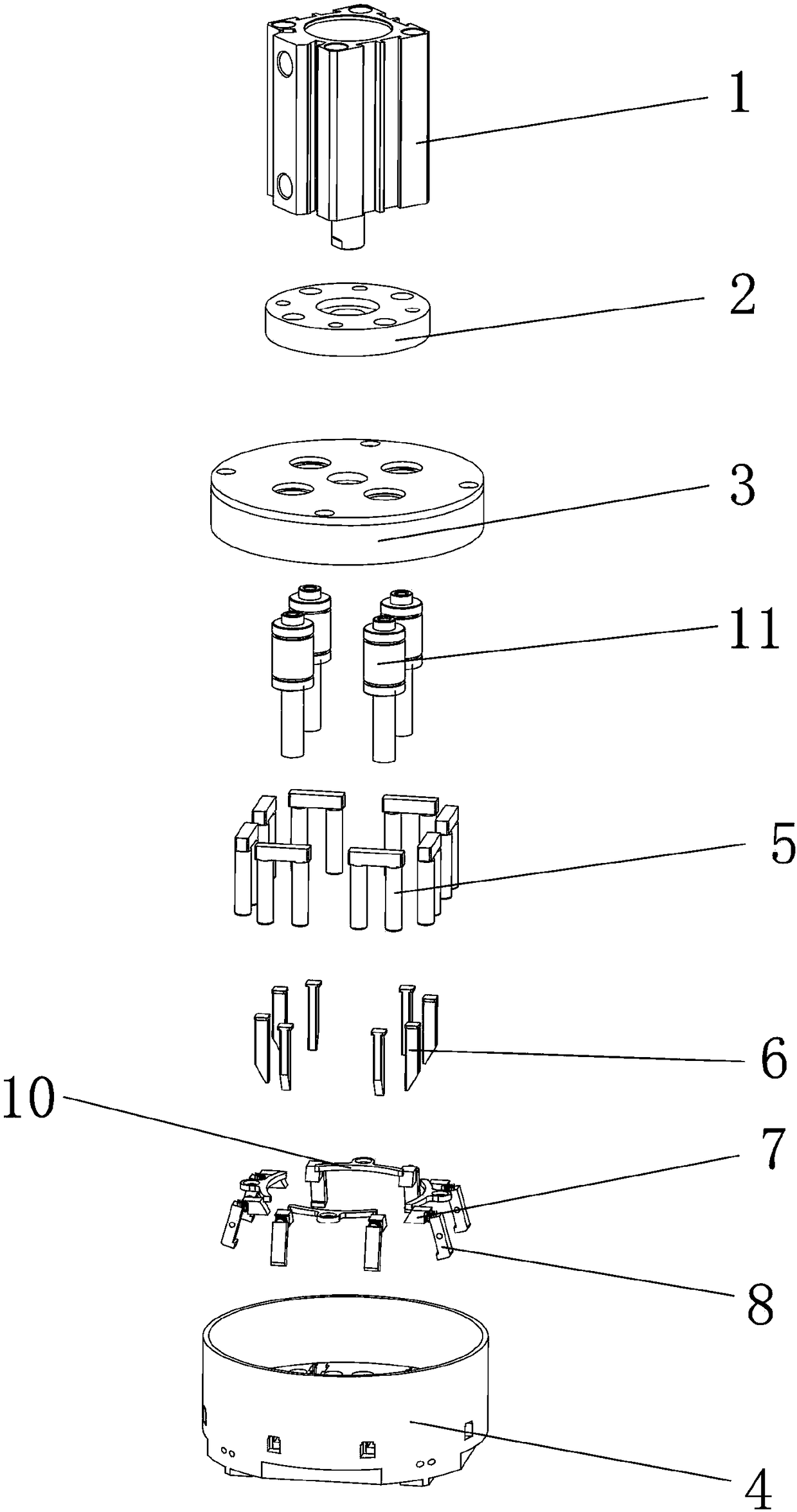

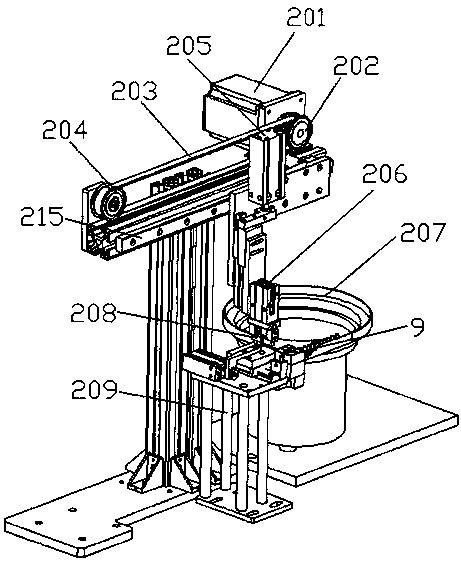

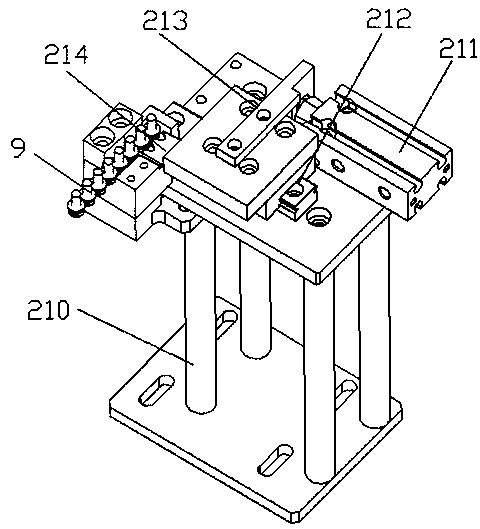

Magnet gripping device

The invention relates to a magnet gripping device which comprises an air cylinder, an air cylinder mounting plate and a movable seat, wherein the air cylinder is mounted above the air cylinder mounting plate; an air cylinder piston rod penetrates through the air cylinder mounting plate downwards to be connected with the movable seat; the lower part of the movable seat is mounted in the cavity of agripping seat in a sleeving manner; a plurality of guide rods vertically downwards and a plurality of female wedge blocks are mounted at the bottom of the movable seat; the gripping seat is providedwith a guide hole, a wedge block mounting groove and a gripper mounting groove; sub wedge blocks are horizontally mounted in the wedge block mounting groove; a gripper is rotatably mounted in the gripper mounting groove through a pivot; the air cylinder drives the movable seat to move downwards; the movable seat moves downwards under the precise guiding function of the guide rods and the guide hole; the female wedge blocks move downwards to drive the sub wedge blocks to move outwards through inclination plane movement; the sub wedge blocks drive the gripper to rotate and shrink through a spring; the gripper and a limiting boss jointly clamp and grip magnets; the gripper elastically grips the magnets to prevent the magnets from rigid stressed damage; and in addition, the number of the gripper is increased according to the actual demand, so that the number of the magnets gripped at one time is large to meet the production demand.

Owner:东莞龙昌数码科技有限公司

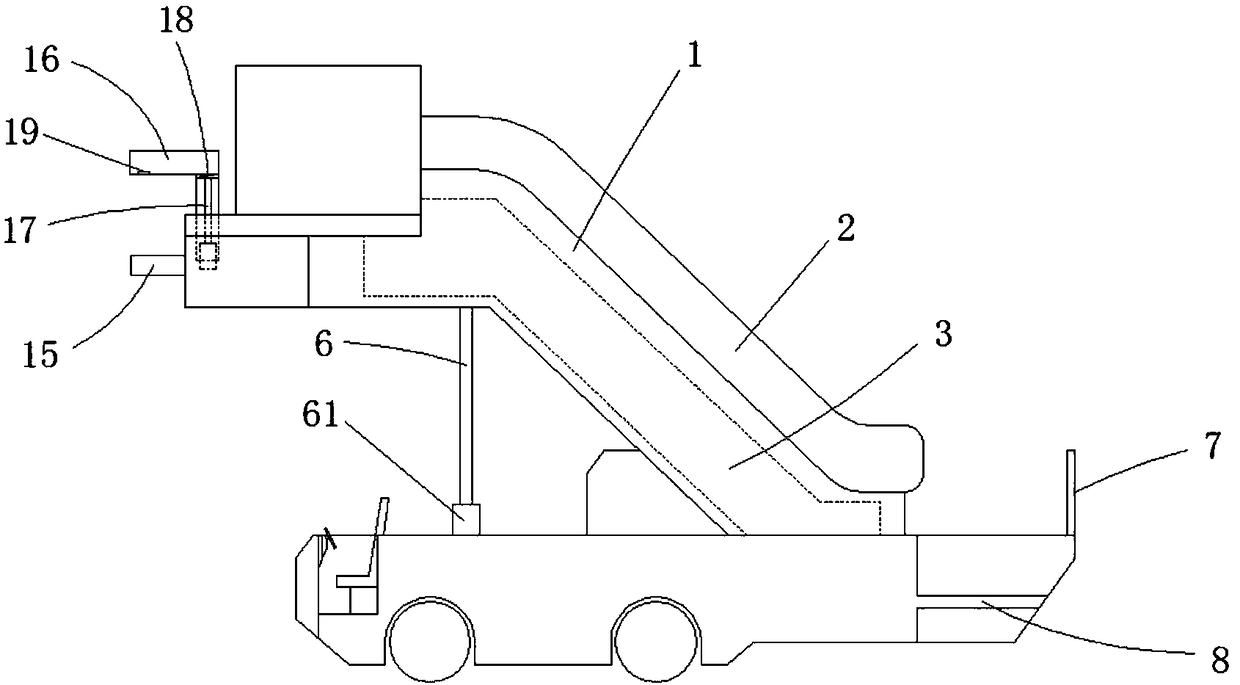

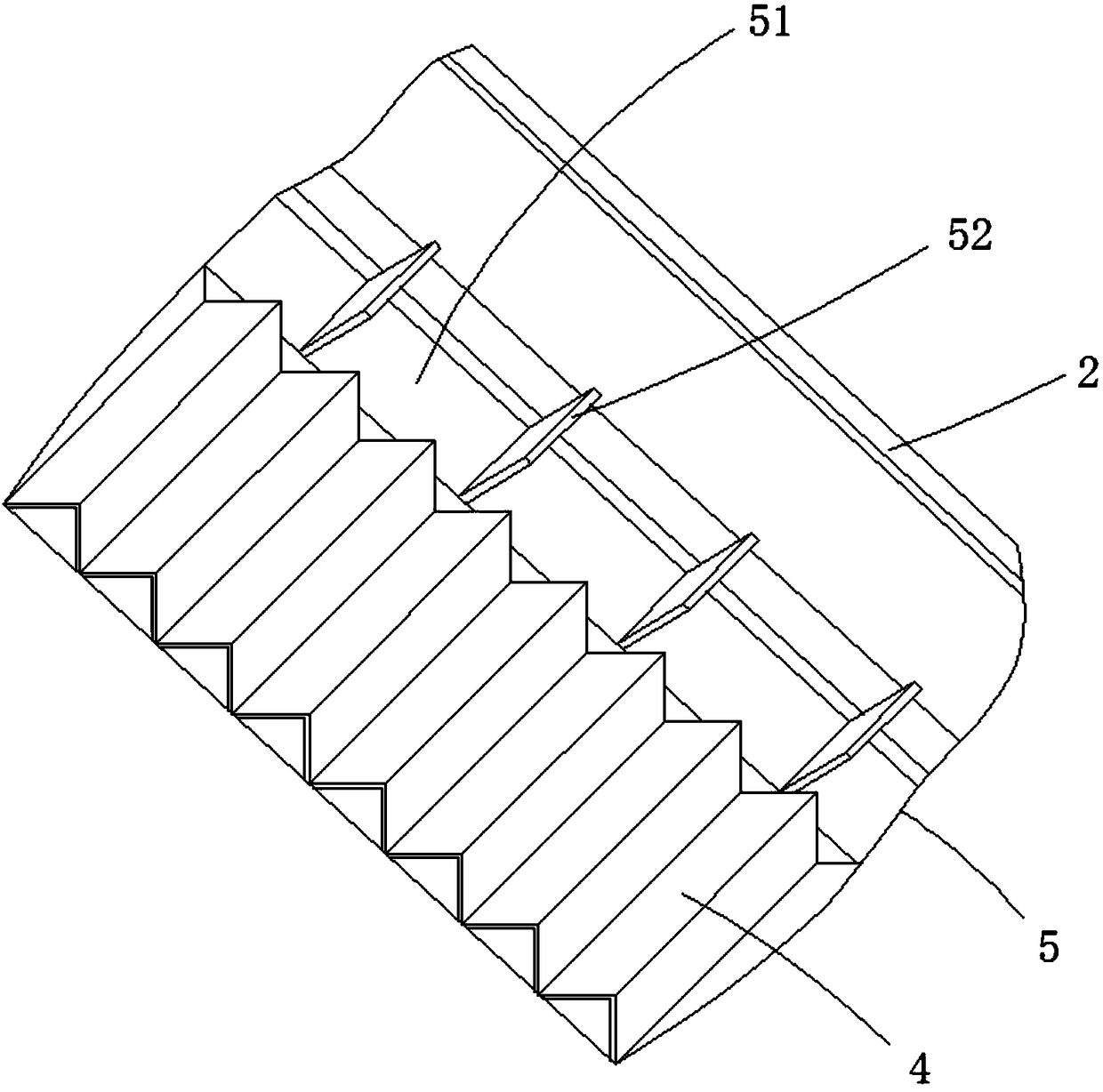

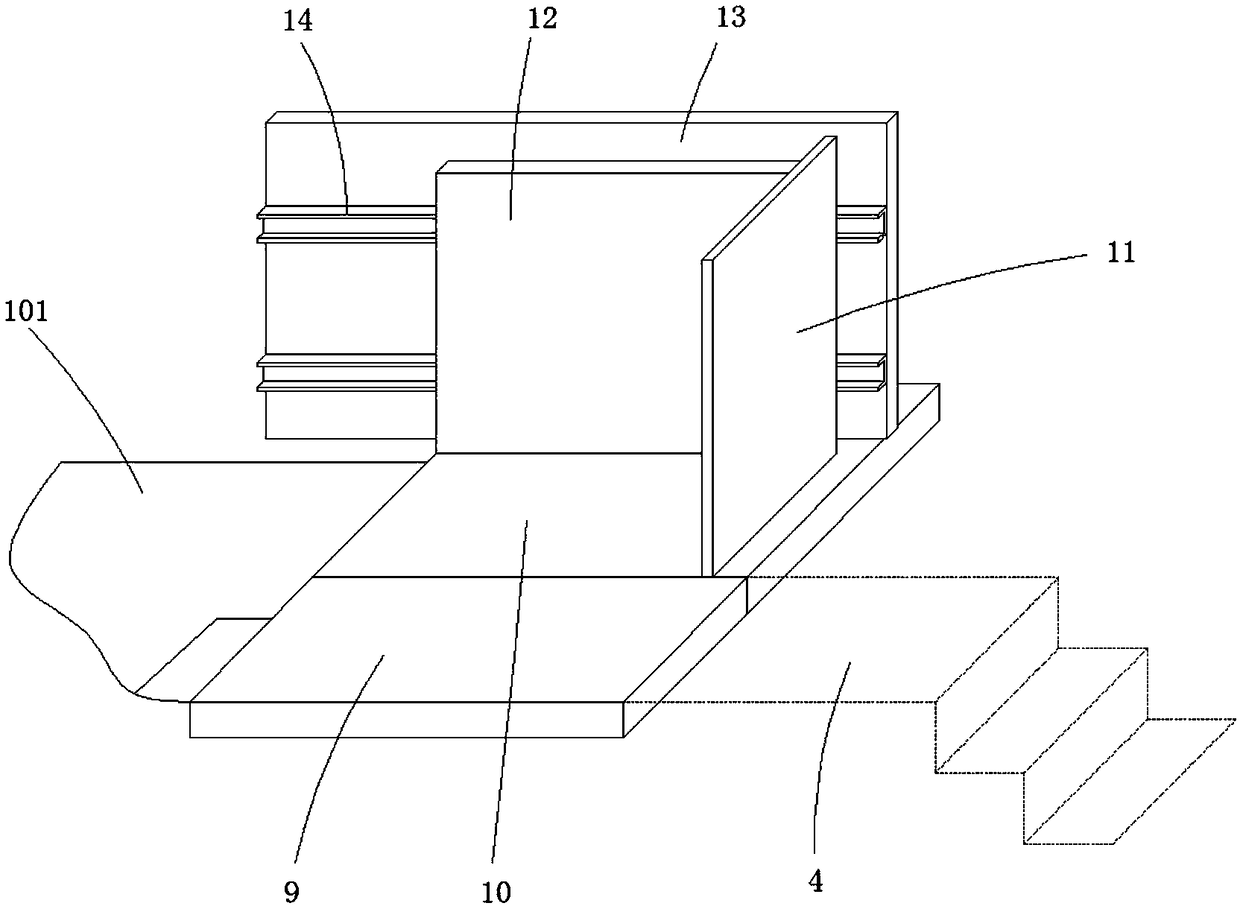

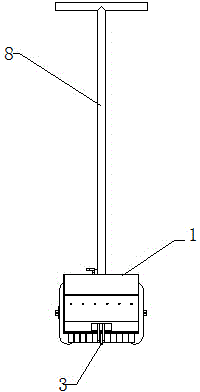

Vehicle-mounted escalator for boarding and working method of vehicle-mounted escalator

PendingCN108190706AStable structureSolve shipping security issuesGround installationsEscalatorsEngineeringHandrail

Owner:SUZHOU ZHILVE INTELLECTUAL PROPERTY OPERATION CO LTD

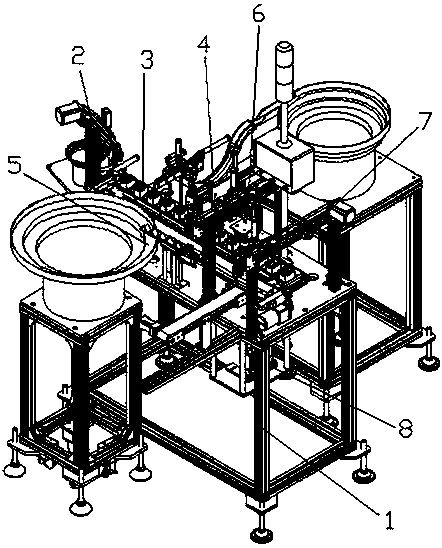

Automatic screw locking machine for cooling fin

The invention relates to a heat sink automatic screw locking machine, which includes a frame and a power distribution control box arranged in the frame, a main body circulation flow channel is arranged in the middle of the upper end of the frame, and the starting end of the main body circulation flow channel is connected to a screw feeding device , the side edge is provided with a triode feeding device, a heat sink feeding device and a feeding device in turn along the forward direction, a pressing device is arranged above, and a locking screw device corresponding to the pressing device is installed below, the main circulation channel includes a fixed on the machine The feeding channel on the frame, one side of the feeding channel is provided with a return conveyor belt, the two ends are provided with a push jig cylinder, and the lower end is connected with a forward pushing mechanism; the present invention realizes each station by pushing forward the jig through the forward pushing mechanism. The positioning of the assembly is realized under the action of the jig limit mechanism, and then the jig is pushed to the return conveyor belt through the symmetrically set push jig cylinder and the push jig plate, and the return conveyor belt carries the jig back, so that Realize cycle, simple structure, strong applicability.

Owner:DONGGUAN UNIV OF TECH

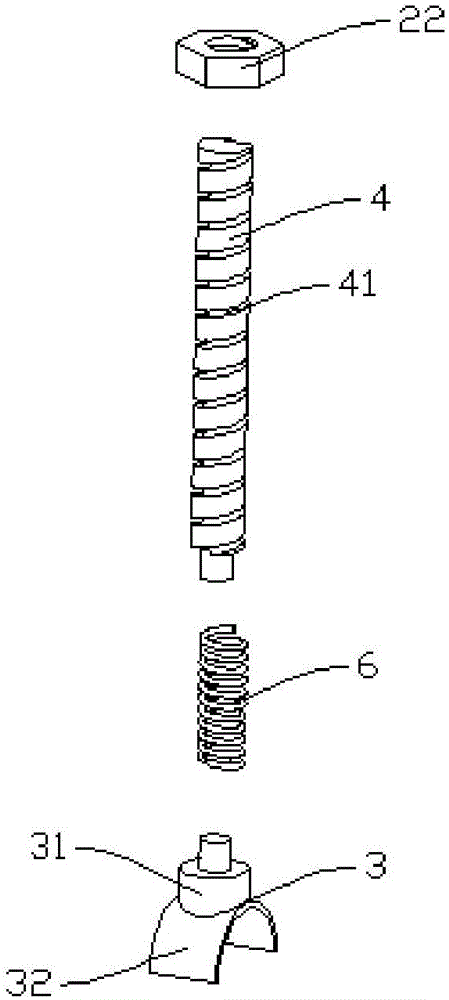

Multi-cushioning compaction device

InactiveCN106475813ARelieve stress concentrationAvoid rigid damagePositioning apparatusMetal-working holdersCushioningEngineering

The invention provides a multi-cushioning compaction device. The device comprises a vertical arm, a cantilever, a pressing head and a connecting rod, wherein a thread is formed in the connecting rod, and a nut is fixed on the cantilever; a strip groove is formed in the upper surface of the cantilever, and the connecting rod can run through the connecting rod; and fixing plates are arranged on two sides of the strip groove, and are used for fixing the nut. According to the multi-cushioning compaction device, the position of the connecting rod can be adjusted, and the nut can be stably fixed on the cantilever.

Owner:天津艳萍科技有限公司

Wind-proof pull rod for crane

Owner:长沙雅创智能科技有限公司

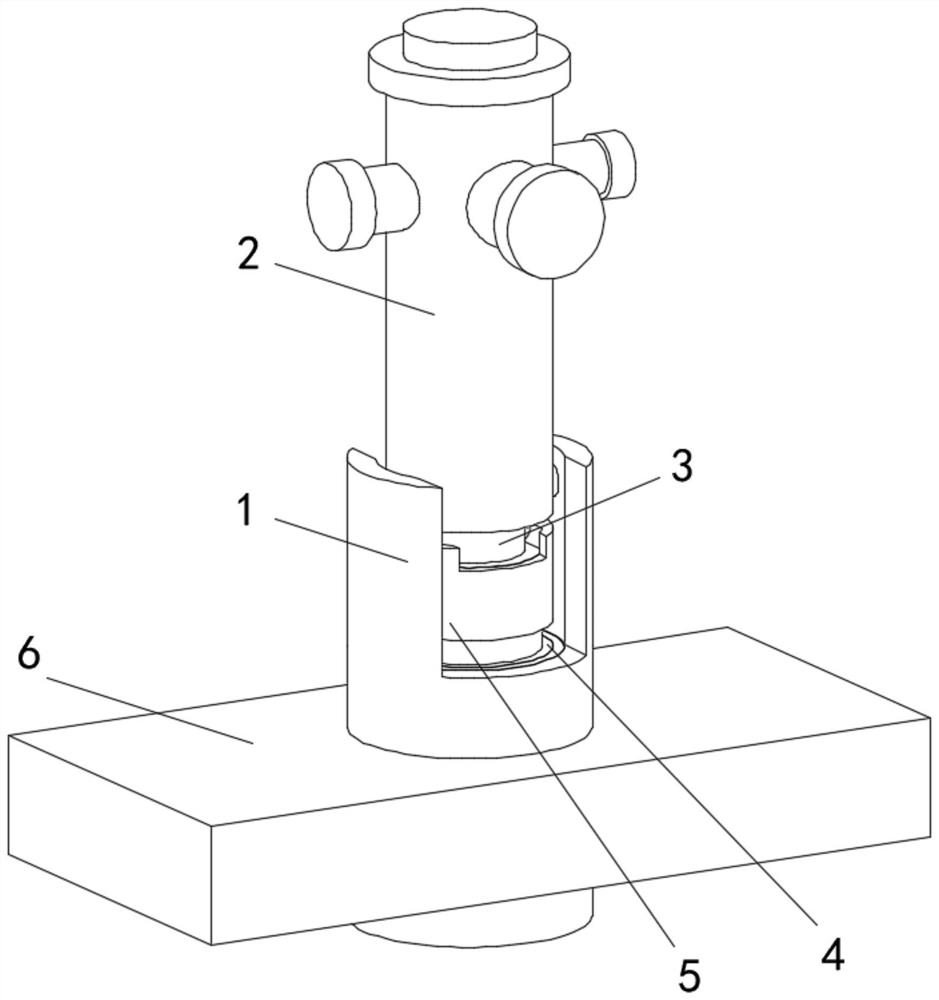

Device for preventing fire hydrant from being damaged by impacting

ActiveCN111962611AAvoid rigid damageGuaranteed working lifeDrawing-off water installationsTransmission beltWater resources

The invention relates to the technical field of security and protection, and discloses a device for preventing a fire hydrant from being damaged by impacting. The device comprises a column base, wherein the outer surface of the column base is fixedly connected with the ground, the lower half section of the column base is located in the ground, a water conveying pipe is arranged in an inner cavityof the column base, the upper end of the inner cavity of the column base is movably connected with a spherical valve located above the water conveying pipe, and the upper end of the inner cavity of the column base is fixedly connected with a second fixed magnet located above the spherical valve. By a rotary fire hydrant, when the upper end of the fire hydrant is greatly impacted, a fire-fighting column can rotate around a second rotating shaft to prevent rigid damage to the fire-fighting column; meanwhile, through transmission of a transmission belt, the spherical valve synchronously rotates under transmission of the second rotating shaft, the water conveying pipe is closed through the spherical valve, leakage of a large amount of water resources is avoided, the situation that after a traditional fire hydrant is greatly impacted, the fire hydrant is broken, and leakage of a large amount of water resources is caused is avoided, and the service life of the fire hydrant is guaranteed.

Owner:芜湖市启舸流体技术有限公司

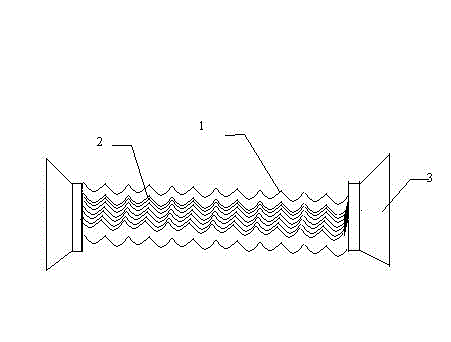

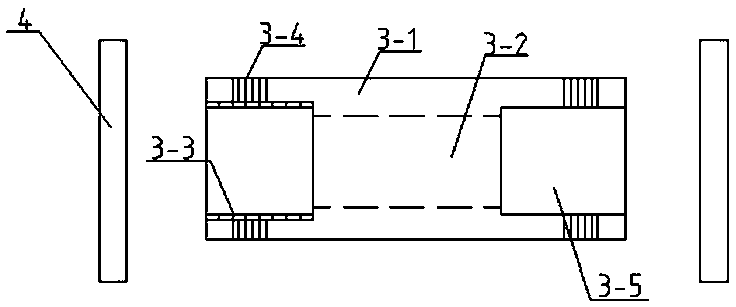

Wind power bus connector

InactiveCN103560457AAvoid rigid damageSimple structureBus-bar installationElectricityElectrical conductor

The invention relates to a novel wind power bus connector. The novel wind power bus connector comprises a rubber pipe and a tubular flexible conductor, wherein the rubber pipe and the tubular flexible conductor are to be connected, the tubular flexible conductor is arranged in the rubber pipe, and the rubber pipe is arranged in a wavy mode. Metal sleeves are arranged at the two ends of the rubber pipe respectively, each metal sleeve can be conveniently and fixedly connected with a busbar in a corresponding bus duct into a whole, and each metal sleeve is in a horn shape. When the wind power bus connector is used, the tubular flexible conductor is made to penetrate through the rubber pipe, and the metal sleeves on the rubber pipe are connected to the bus ducts in a welding mode. The wind power bus connector is simple in structure and convenient to manufacture and install, and meanwhile due to the flexible connection structure of soft connection, wind power busses can swing in a wind power tower, and rigidity damage, caused by wind, to electric bus parts can be avoided.

Owner:XIANGRONG ELECTRIC GRP

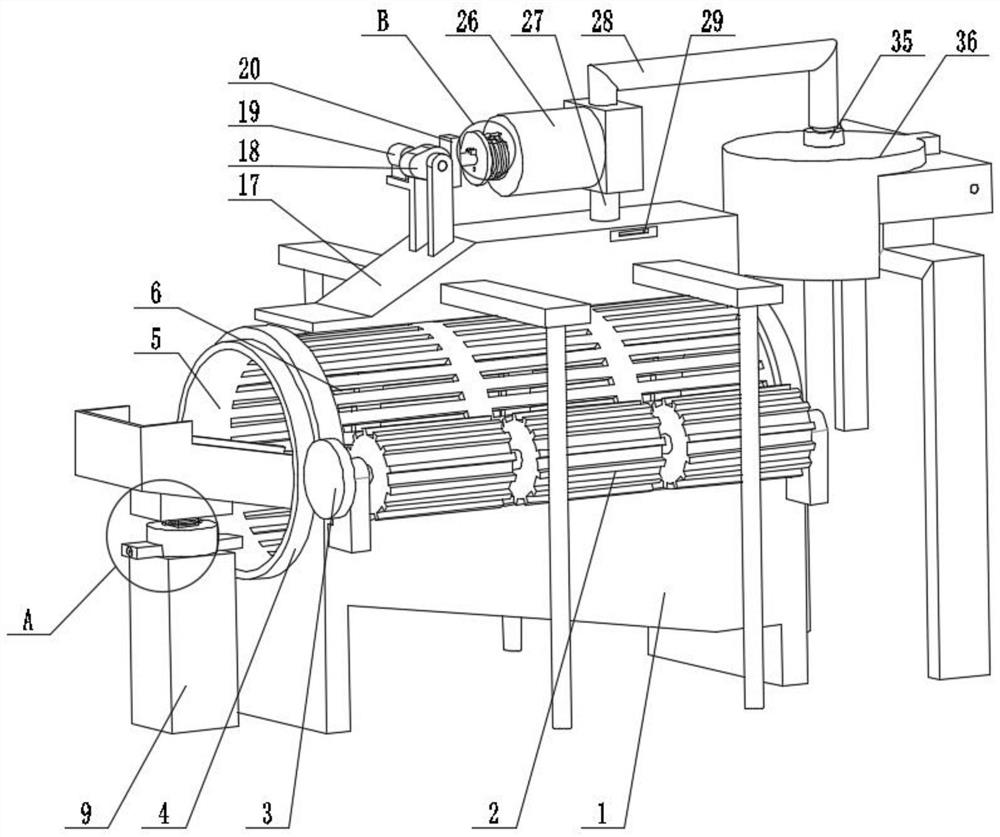

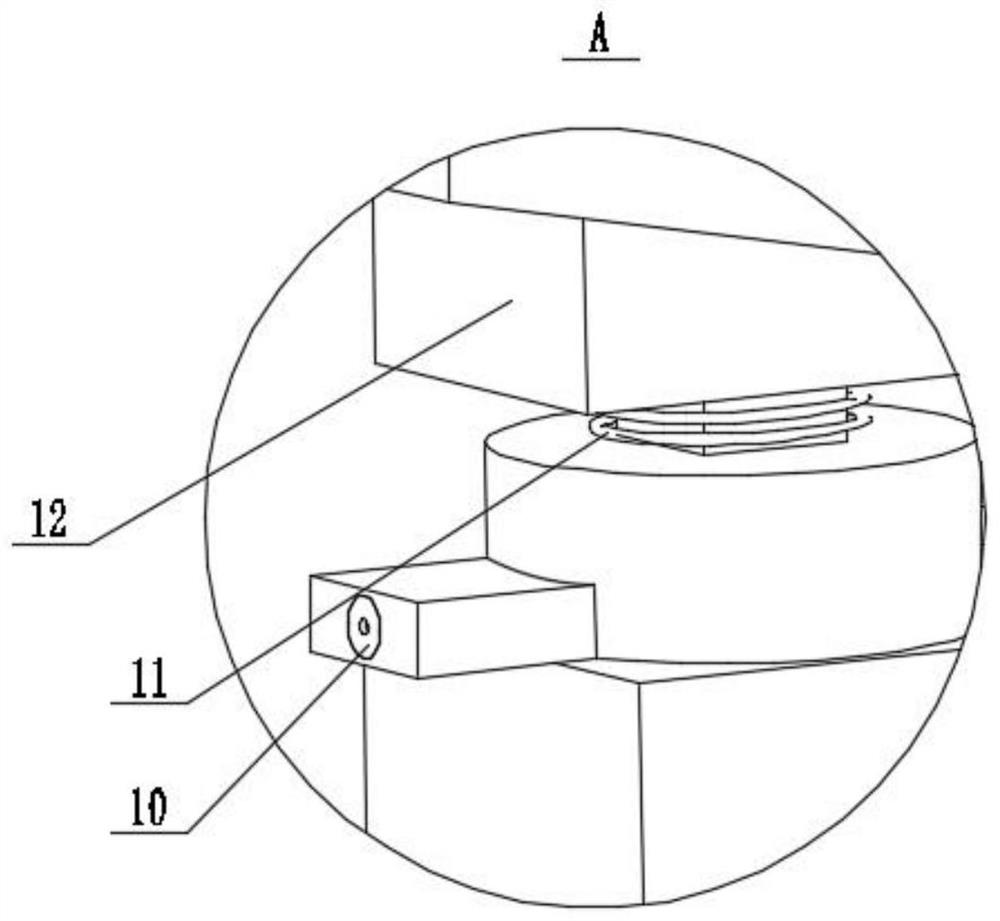

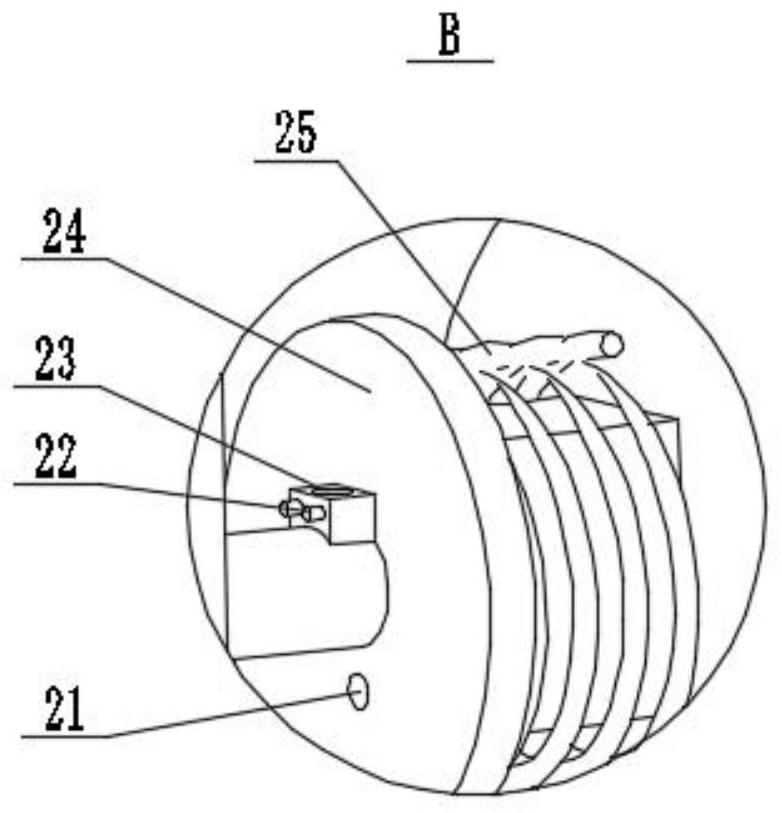

Environment-friendly garbage dump garbage separation drum screen device

ActiveCN113600468ASolve the problem of dustAvoid rigid damageSievingScreeningWaste dumpElectric machinery

The invention provides an environment-friendly garbage dump garbage separation drum screen device which comprises a rotary supporting frame with an inclined hopper. A rotary drum is rotationally connected to the rotary supporting frame with the inclined hopper, a feeding port and a large material discharging port are formed in the two ends of the rotary drum correspondingly, and a fine material outlet is formed in the rotary supporting frame with the inclined hopper. Tooth-shaped long-strip screen holes are formed in the rotary drum, a belt shaft driving cleaning gear is rotationally connected to the rotary supporting frame with the inclined hopper, the belt shaft driving cleaning gear is engaged with the tooth-shaped long-strip screen holes, the belt shaft driving cleaning gear is provided with a matched driving motor, and cleaning to the screen holes is completed in the screening process. By means of the device, cleaning to the screening holes can be completed in the screening process.

Owner:陈凌霞

Steel structure bridge connecting device

InactiveCN109296601AInhibit sheddingIncrease the friction surfaceSheet joiningArchitectural engineeringSteel structures

Owner:SHENYANG JIANZHU UNIVERSITY

Bridge anti-seismic support

InactiveCN114427186AAvoid rigid damageGuaranteed stabilityBridge structural detailsRock boltSeismic wave

A bridge anti-seismic support comprises a beam bottom embedded steel plate and a padstone top surface steel plate, a support upper steel plate is fixedly connected with the beam bottom embedded steel plate through an upper anchor rod, a support lower steel plate is fixedly connected with the padstone top surface steel plate through a lower anchor rod, the support upper steel plate is located on the inner side of the support lower steel plate, and a cavity is defined by the support upper steel plate. The cavity is filled with the transversely-placed middle buffering energy-absorbing block, the support lower steel plate and the support upper steel plate are oppositely arranged in the opposite directions, the side face of the support lower steel plate and the side face of the support upper steel plate are oppositely arranged, and the space between the side face of the support upper steel plate and the side face of the support lower steel plate is vertically filled with the peripheral buffering energy-absorbing block. The buffer energy-absorbing block can effectively prevent rigid damage of seismic waves to the bridge. The bridge anti-seismic support guarantees the stability of a bridge, is safe, reliable, high in buffering capacity and large in absorbed energy, has the advantages of being easy to manufacture and convenient to install, and has high practicability.

Owner:河北创泰交通工程技术有限公司

Plate sorting and conveying device

PendingCN107010391AFast shippingAvoid damageConveyorsDe-stacking articlesStructural engineeringMechanical engineering

The invention discloses a plate sorting and conveying device which comprises a support, a material containing box, a guide rail and an air cylinder. The material containing box is supported through the support. A feeding opening is formed in the top of the material containing box, and a discharging opening is formed in the bottom of the material containing box. A baffle is arranged in the manner of extending downwards along the bottom edge of the outer side wall of the material containing box. The bottom end of the baffle horizontally extends towards the middle of the discharging opening to form clamp plates. A plate guide cavity is formed among the clamp plates and the discharging opening. A plate horizontal pushing rod capable of pushing a to-be-pushed-out plate out of the plate guide cavity is arranged in the plate guide material. A piston of the air cylinder is fixedly connected with the plate horizontal pushing rod. The distance between the clamp plates and the feeding opening is equal to the thickness of the to-be-pushed-out plate. The plate horizontal pushing rod pushes the plate out of the plate guide cavity through the air cylinder. The guide rail for bearing the pushed-out plate is arranged below the plate guide cavity. The plate sorting and conveying device has the beneficial effects that the plate can be transported fast, and the situation that during manual carrying, the plate is damaged, and labor force is wasted can be avoided.

Owner:CHENGDU ZHENZHONG ELECTRIC

Novel stereoscopic part library with input end capable of being adjusted

The invention relates to the field of a conveying device, in particular to a novel stereoscopic part library with the input end capable of being adjusted. The novel stereoscopic part library comprises a bearing device erected according to production environment. A part rack is correspondingly arranged above the bearing device. A conveying chain is arranged in the part rack in the mounting direction. The part rack comprises a plurality of connected linear conveying segments and corner conveying segments. The ends of every two parallel linear conveying segments are connected through the corresponding corner conveying segment. In the novel stereoscopic part library, at least one corner conveying segment serves as the input end of the part rack, and the input end comprises an arc-shaped segment and extending segments. The arc-shaped segment is in an arc shape, and the two parallel extending segments are integrally manufactured on the two side ends of the arc-shaped segment respectively, and the outer edges of the ends of the two extending segments are each sleeved with the end of one side of an extending sleeve in a sliding manner. The ends of the other sides of the two extending sleeves are arranged at the two ends of the two linear conveying segments in a sleeving manner. The input end can bidirectionally move in the extending sleeves in the horizontal direction.

Owner:凯兰德运动科技股份有限公司

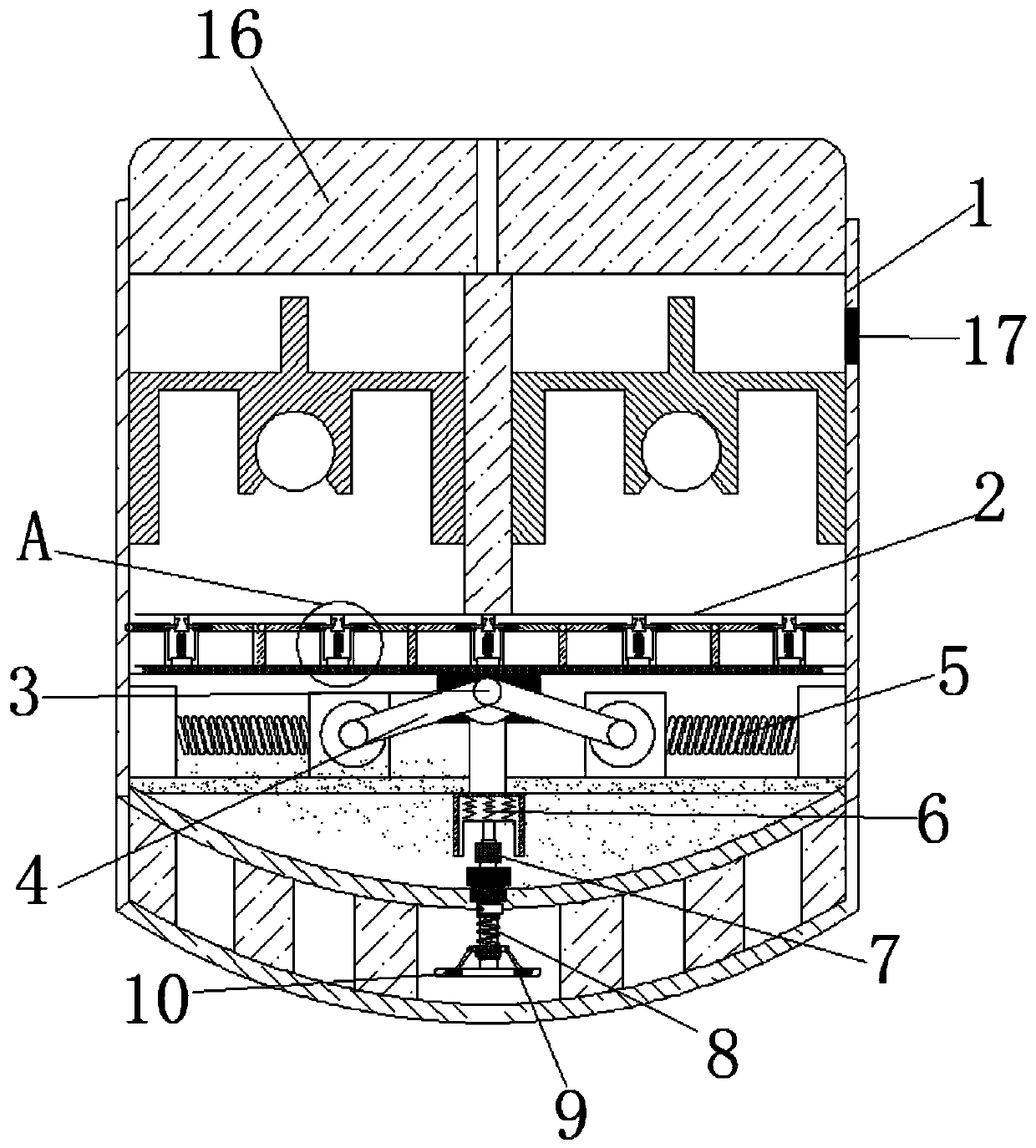

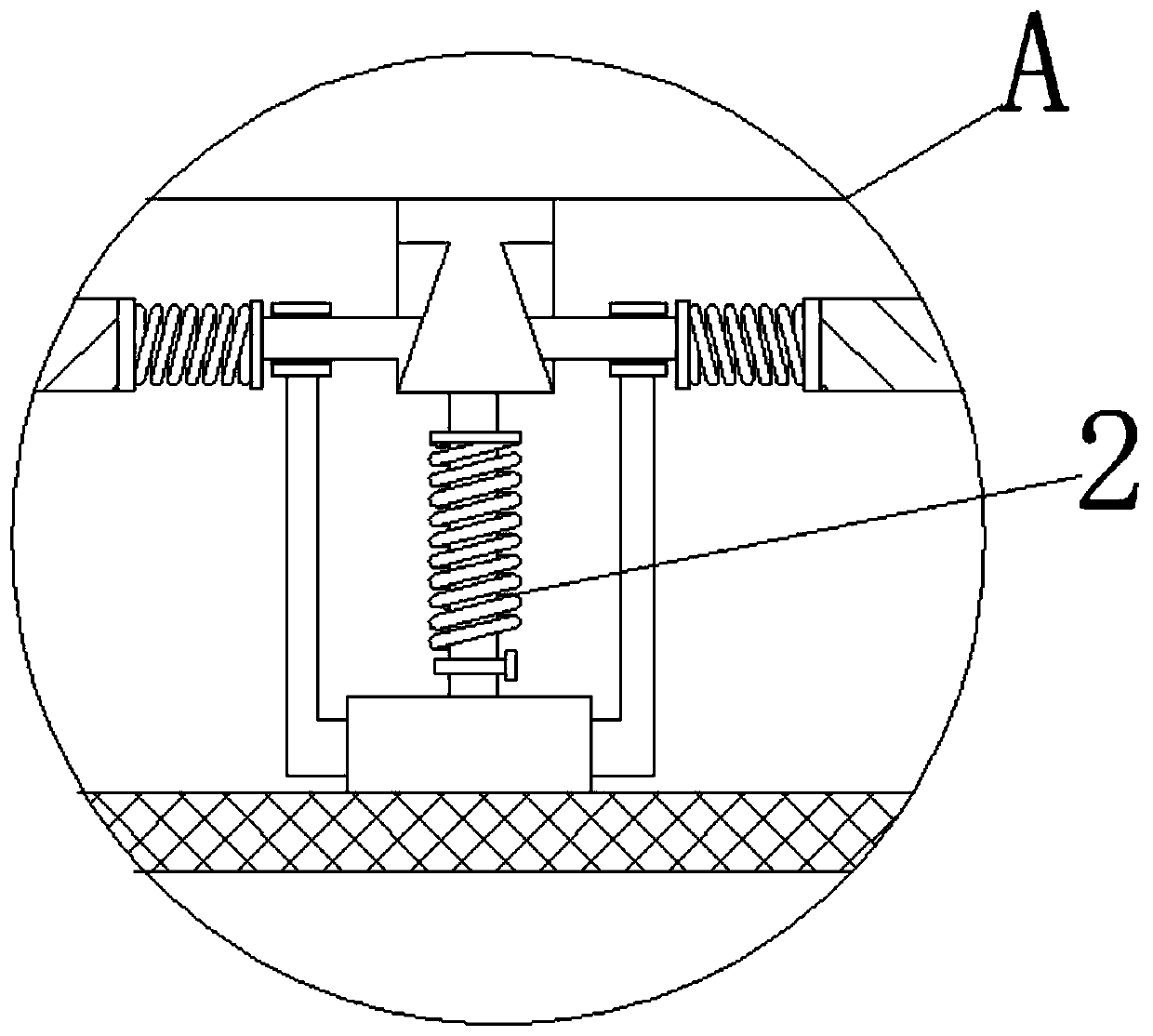

Building steel structure transfer device

PendingCN112706811AAvoid rigid damageImprove shock absorptionSupporting partsVibration suppression adjustmentsClassical mechanicsEngineering

The invention discloses a building steel structure transfer device, which belongs to the technical field of damping steel, and comprises a support plate, the middle of the lower surface of the support plate is fixedly connected with the top end of a fixing rod, and the bottom end of a fixing column penetrates into a spring cavity and is fixedly connected with the upper surface of a limiting plate; the lower surface of the limiting plate is fixedly connected with the top end of a damping spring, the bottom end of the damping spring is fixedly connected to the inner wall of the bottom end of a spring cavity, the bottom end of the spring cavity is fixedly connected with the upper surface of a bottom plate, fixing blocks are fixedly connected to the upper surfaces of the bottom plate at the two sides of the spring cavity, the top ends of the fixing blocks are hinged to a first hinge rod, and the bottom end of the first hinge rod is fixedly connected with the upper surface of the bottom plate through a compression spring; by arranging the damping spring, the compression spring and a telescopic rod, triple pressure reduction is achieved on the supporting plate, rigid damage to the supporting plate due to the fact that steel is too heavy is avoided, and a good damping effect is achieved on the device.

Owner:JIANGYIN JIANHE STEEL CO LTD

Quick positioning device for hardware processing

InactiveCN110026925AReduce the difficulty of operationImprove processing efficiencyWork holdersLocking mechanismEngineering

The invention relates to a quick positioning device for hardware processing. The quick positioning device for hardware processing comprises a frame body, a locking mechanism, resetting mechanisms, buffering mechanisms and sliding rods, wherein a threaded rod is hinged to the center of the left side wall of the frame body through a bearing; a rocking handle is fixed to the left end of the threadedrod; stand columns are hinged to the positions, in the frame body, on two sides of the threaded rod; linkage rods are arranged in the middles of the stand columns in a sleeving way; pull rods are hinged to the right ends of the linkage rods; a fixed plate is arranged on the left side in the frame body; a cover plate is clamped to the top part of the frame body on the left side of the fixed plate;the sliding rods are hinged to two sides in the fixed plate through bearings; the buffering mechanisms are arranged at the corresponding positions in the middles of a movable plate and the fixed plate; and the resetting mechanisms are arranged on the right parts of the sliding rods in a sleeving way. According to the quick positioning device for hardware processing, the processing efficiency of hardware products is improved, the operation difficulty of the positioning device is reduced, and the hardware products are prevented from being rigidly damaged.

Owner:ZHONGSHAN FENGSHEN ELECTRICAL APPLIANCE CO LTD

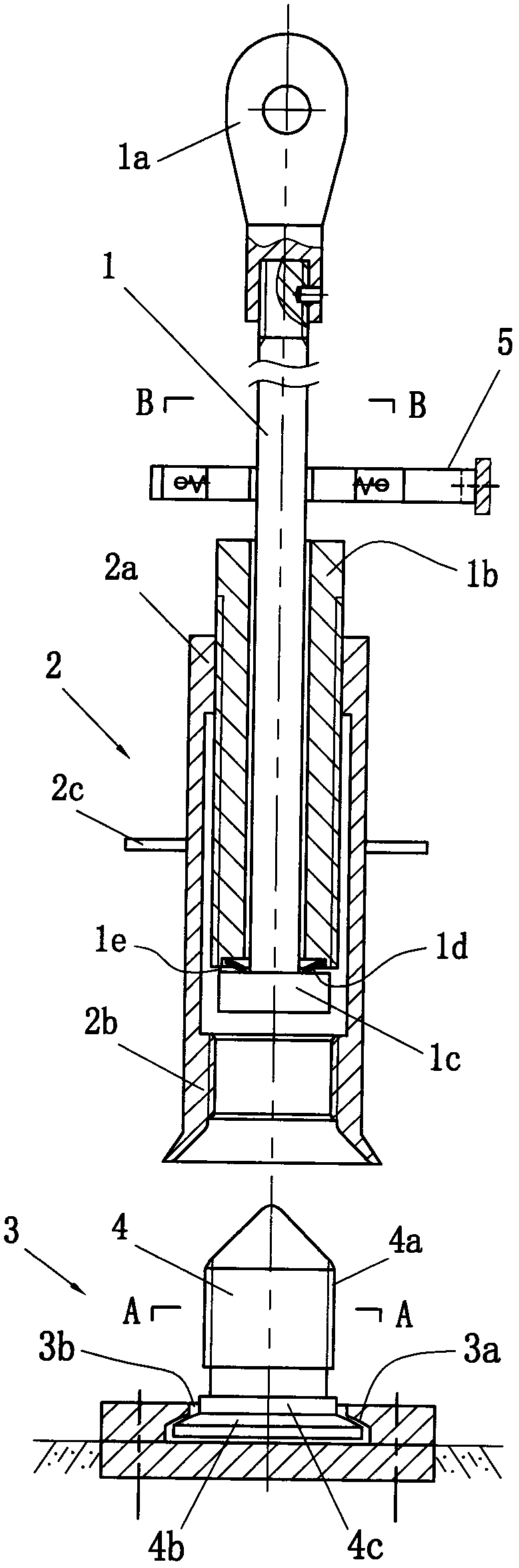

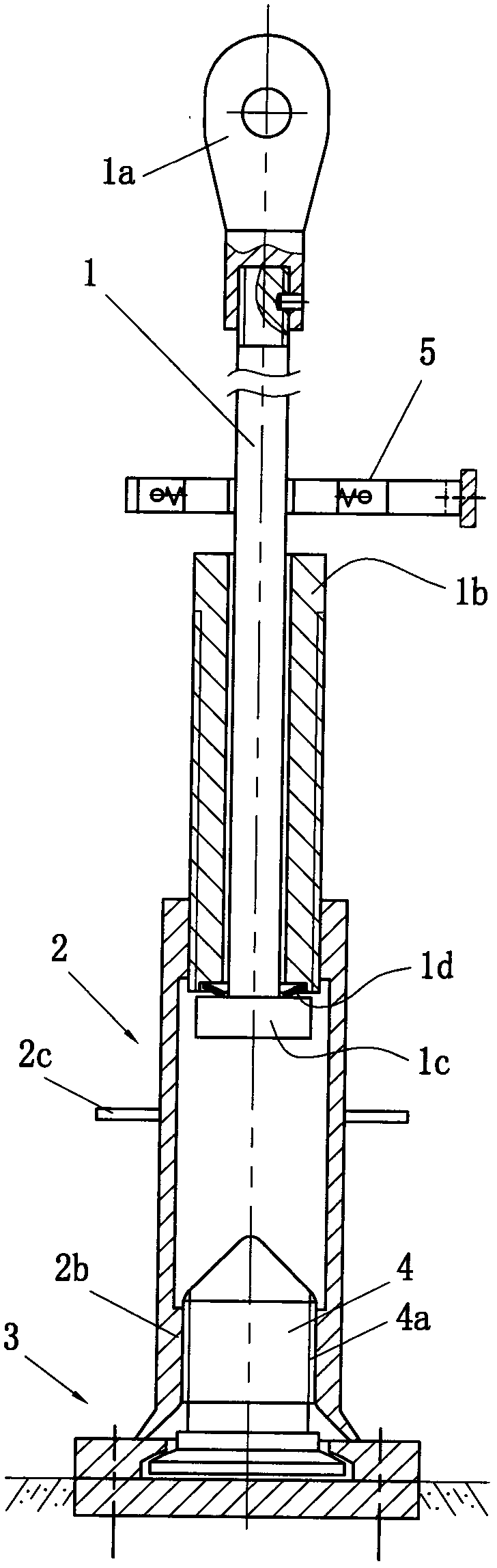

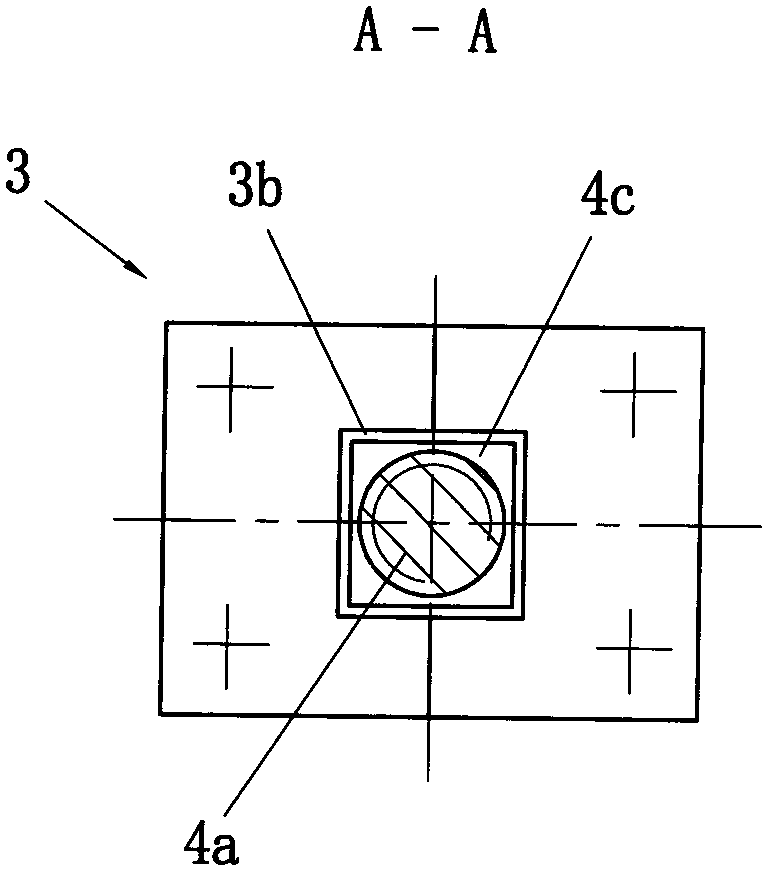

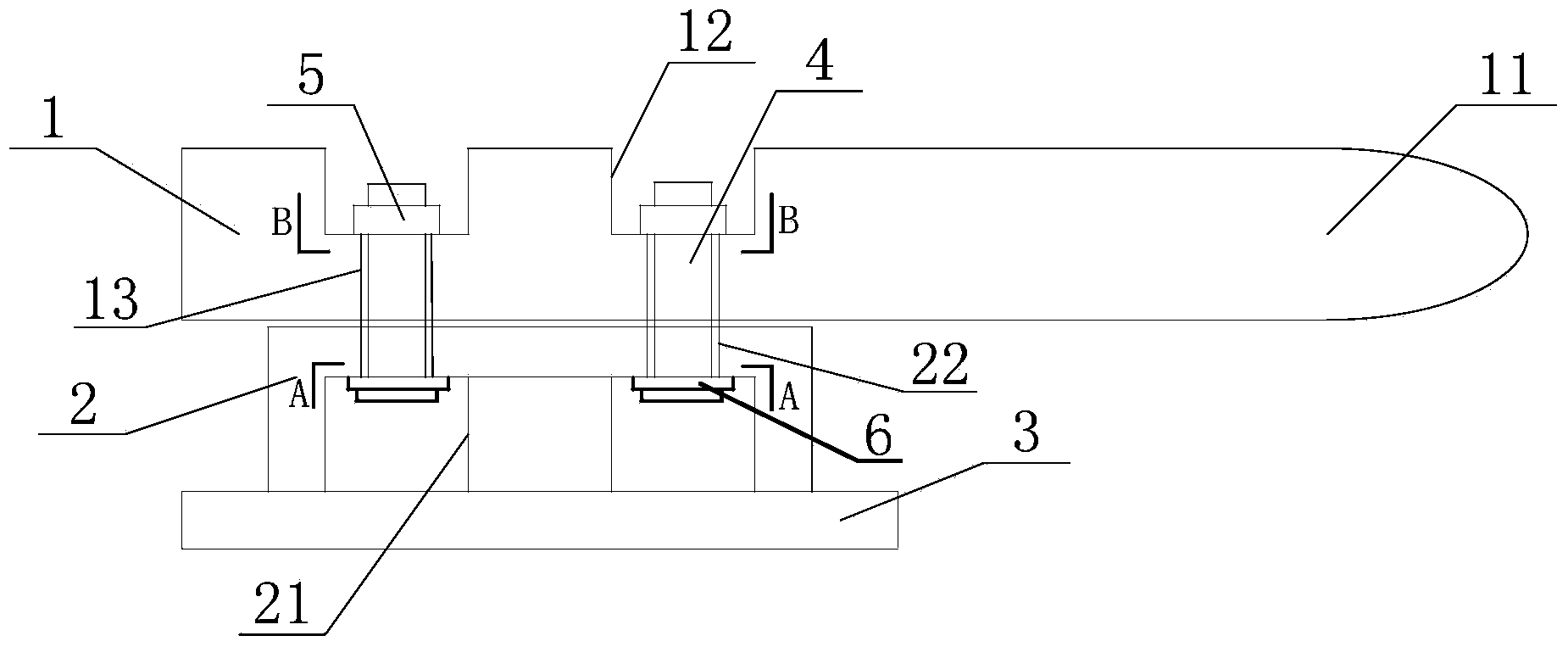

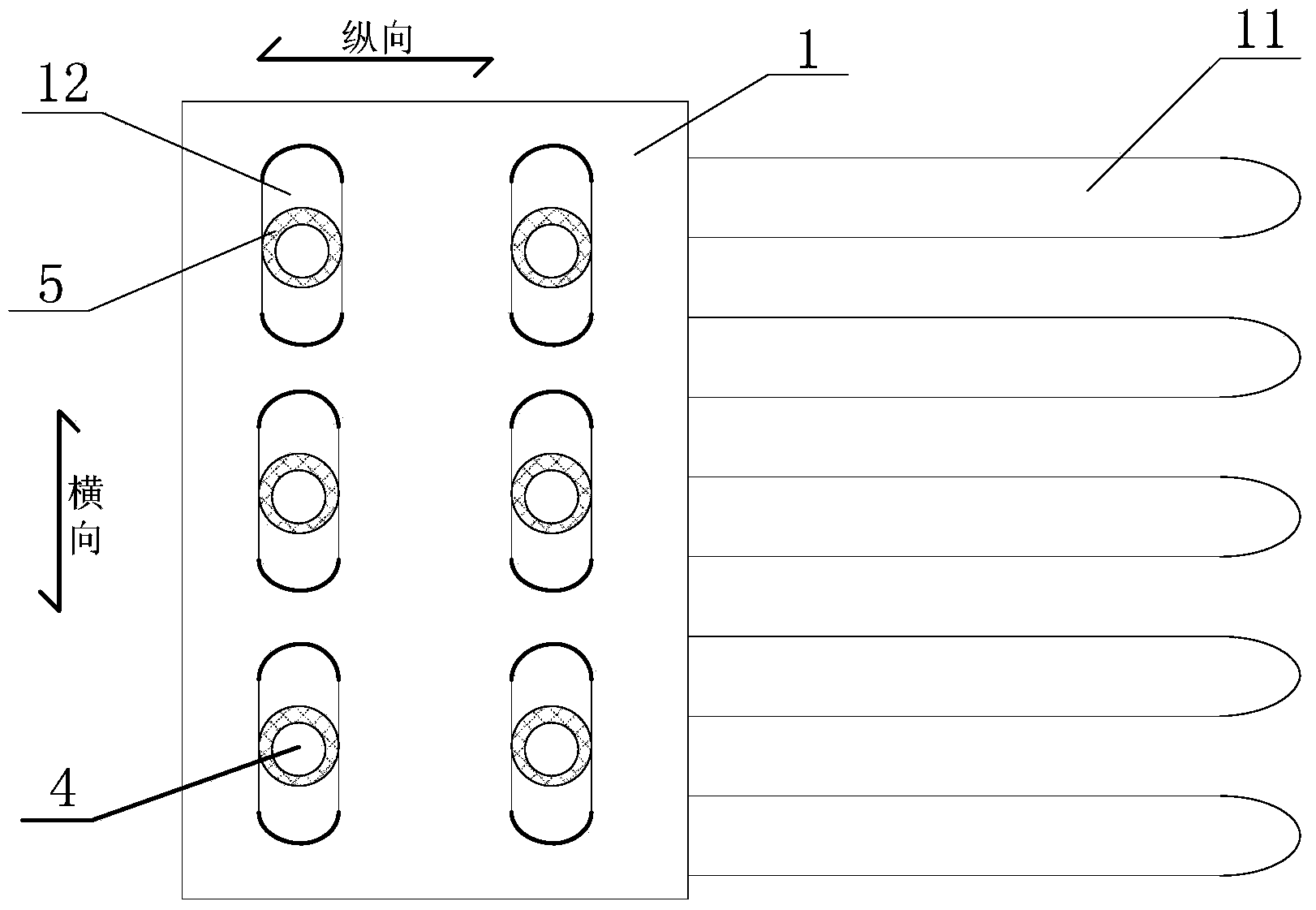

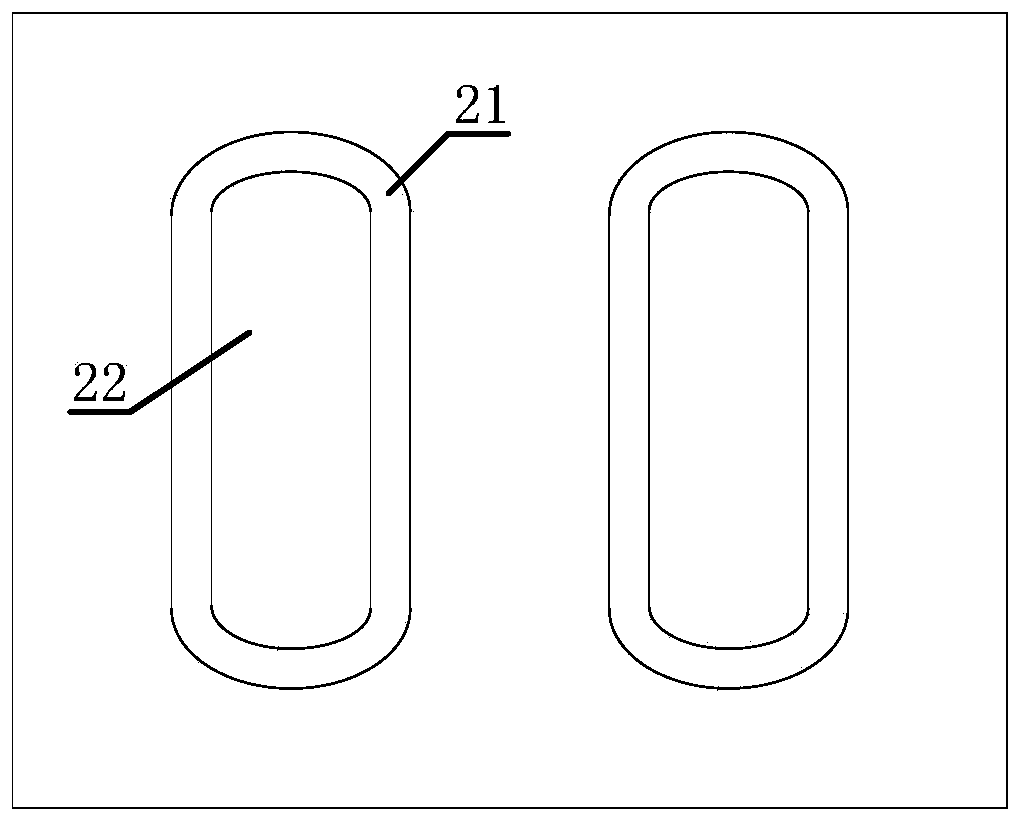

Comb-tooth-type expansion joint with position capable of being transversely changed

InactiveCN103924511AImprove seismic performanceAvoid rigid damageBridge structural detailsChange controlEngineering

Disclosed is a comb-tooth-type expansion joint with the position capable of being transversely changed. The comb-tooth-type expansion joint comprises a movable comb plate capable of moving longitudinally, a bottom plate and a transverse position change control device arranged between the movable comb plate and the bottom plate. At least one groove is formed in the end, away from comb teeth, of the movable comb plate, and a circular through hole is formed in the bottom of the groove. The transverse position change control device is provided with a transverse kidney-shaped groove corresponding to the groove, and a transverse kidney-shaped through hole attached to the circular through hole is formed in the bottom of the transverse kidney-shaped groove. An anchor bolt penetrating through the through hole and the transverse kidney-shaped through hole can transversely move in the waist direction and is fixed through a nut. When a bridge body of a bridge deviates transversely under the earthquake state, the position of the movable comb plate can be transversely and correspondingly changed through the anchor bolt capable of moving transversely, the rigid damage of transverse clamping of an ordinary comb-tooth-type expansion joint to the whole bridge body of the bridge and a pier can be effectively avoided during earthquake displacement, and the anti-seismic ability of the bridge is improved.

Owner:SUZHOU HAIDER NEW MATERIAL TECH CO LTD

Eleven-head chiseling machine

InactiveCN105756350AIncrease contact areaAvoid rigid damageRoads maintainenceBuilding material handlingGas supply equipmentEngineering

The invention discloses an eleven-head chiseling machine. The machine comprises a machine body, wherein two rows of pneumatic telescopic chiseling heads are arranged at the bottom of the machine body; back sides of the pneumatic telescopic chiseling heads are connected to gas supply equipment through a pipeline; a guiding wheel is arranged in the middle of the front side of the bottom of the machine body; a push wheel support is arranged at the tail of the machine body; a rotating rod is mounted in the middle of the push wheel support; push wheels are mounted on two sides of the rotating rod; a square groove is formed in the middle of the push wheel support; a push rod is hinged inside the square groove; a control plate is mounted on the push rod; multiple keys are arranged on the control plate; the keys and a gas supply equipment control valve are mounted in a matched manner. According to the eleven-head chiseling machine, the contact area of the pneumatic telescopic chiseling heads with the working plane is increased, and the working efficiency is improved; the two rows of pneumatic telescopic chiseling heads are arranged in such a manner that five of the pneumatic telescopic chiseling heads form one row, the rest six pneumatic telescopic chiseling heads form the other row and the two rows are staggered, so that rigid damage to the working plane is prevented; control is directly performed by the aid of the keys arranged on the control plate, and operation is simple.

Owner:TIANJIN YONGMING PRECISION MACHINERY

Ventilation type hog house

Owner:河南恒旺盛源农牧股份有限公司

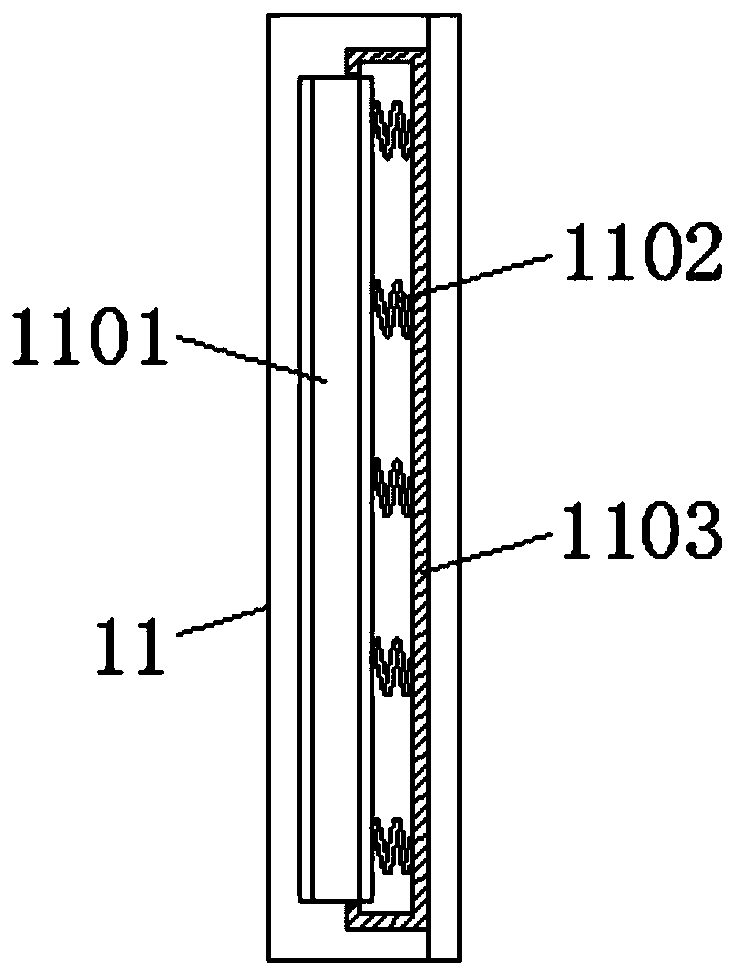

Cleaning device for cleaning inner wall of sewage tank based on gravity variation

InactiveCN111482425AAvoid rigid damageTo achieve the function of removing dirtHollow article cleaningSludgeGear wheel

The invention relates to the technical field of sewage treatment, and discloses a cleaning device for cleaning the inner wall of a sewage tank based on gravity variation. The cleaning device comprisesa sewage tank body. A buffering rail is arranged in the sewage tank body. A pressing block is arranged on the lower side of the buffering rail. A shaft rod is connected with the bottom end of a pressing column. A pushing block is connected with the lower side of the shaft rod. A rotating outer circle gear is connected with the outer side of the pushing block and meshes with an eccentric wheel. The eccentric wheel is connected with the shaft rod. The shaft rod is connected with a cleaning block. The sewage tank body is provided with a sewage outlet. When the cleaning device for cleaning the inner wall of the sewage tank based on gravity variation is used, dirt and a large amount of sludge can be attached to the inner wall and the bottom of the sewage tank body due to long-term use, after too much sludge is accumulated, the buffering rail can be pressed to move under the weight of the sludge at the bottom so as to press the pressing block, connecting rods press the two sides so as to decompose pressing force under the action of springs, and rigid damage is avoided.

Owner:长沙永诺科技有限公司

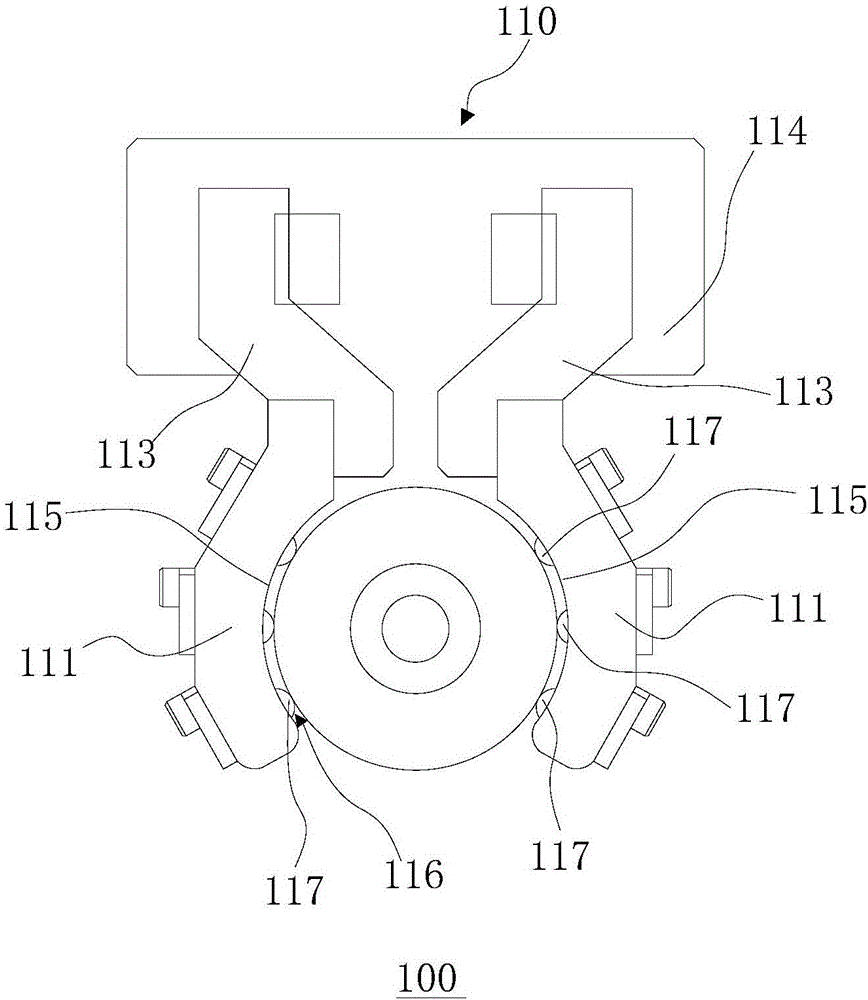

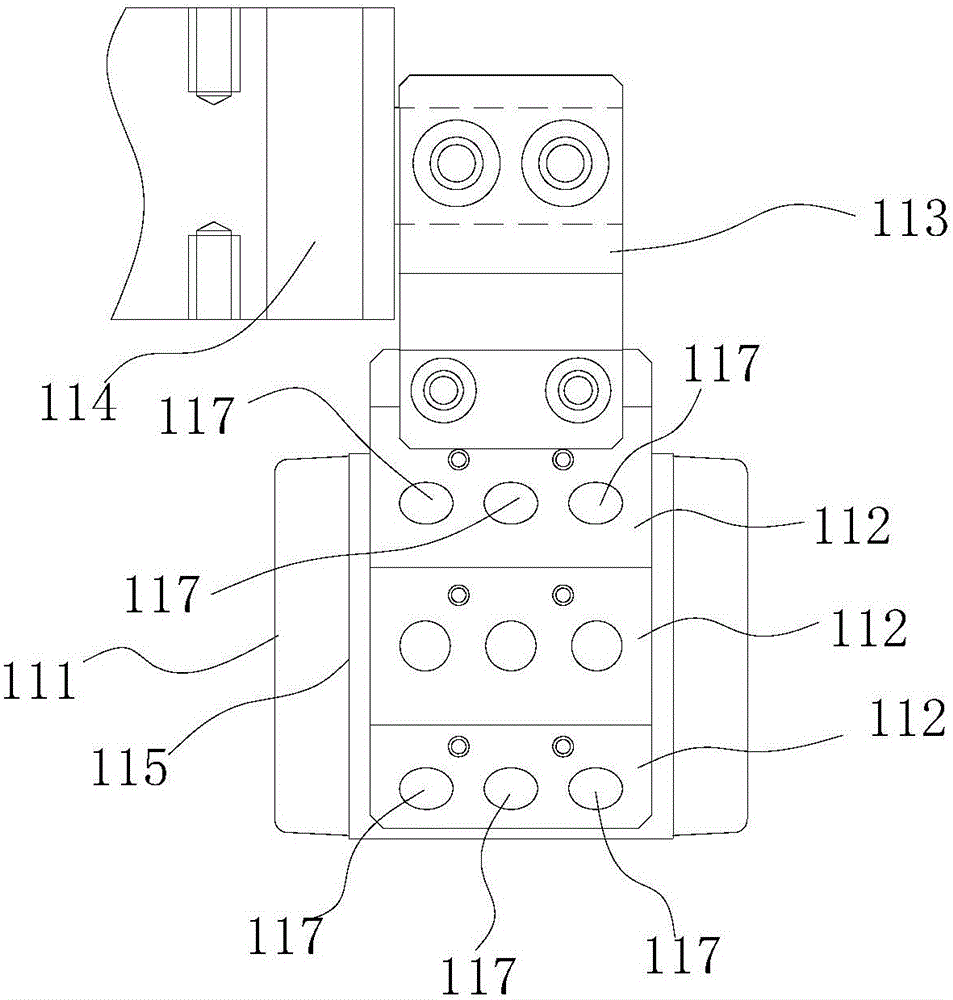

Clamping device for feeding and discharging and robot

The invention provides a clamping device for feeding and discharging. The clamping device comprises a mounting base and a clamping jaw mechanism used for clamping workpieces, wherein the clamping jaw mechanism comprises a plurality of clamping heads; each clamping head is movably connected with the mounting base, and is provided with a working surface and a plurality of floating mechanisms; the floating mechanisms are positioned on the working surface, and each of the floating mechanisms comprises a floating piece; each floating piece is in floating connection with the corresponding clamping head. The floating pieces are arranged on the working surface of each of the clamping heads, so that during clamping the workpieces by the clamping jaw mechanism, when the workpieces are clamped by the clamping heads, the floating pieces act on the surface of each of the workpieces to realize the function of clamping; besides, each of the floating pieces is in floating connection with the corresponding clamping head, so that after being clamped, the workpieces have certain space for free moving, and the workpieces are prevented from being ''completely clamped''. Through the adoption of the clamping device disclosed by the invention, the workpieces can be flexibly mounted at right positions, and rigid damages on the surfaces of the workpieces are avoided. In addition, the invention further provides a robot with the clamping device for feeding and discharging.

Owner:黄石东贝电机有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com