Waste residue crushing device for cement production

A technology of crushing device and waste, which is applied in the direction of grain processing, etc., can solve the problems of increased contact with waste residue, inability to realize automatic discharge, and endangering the life, safety and health of operators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

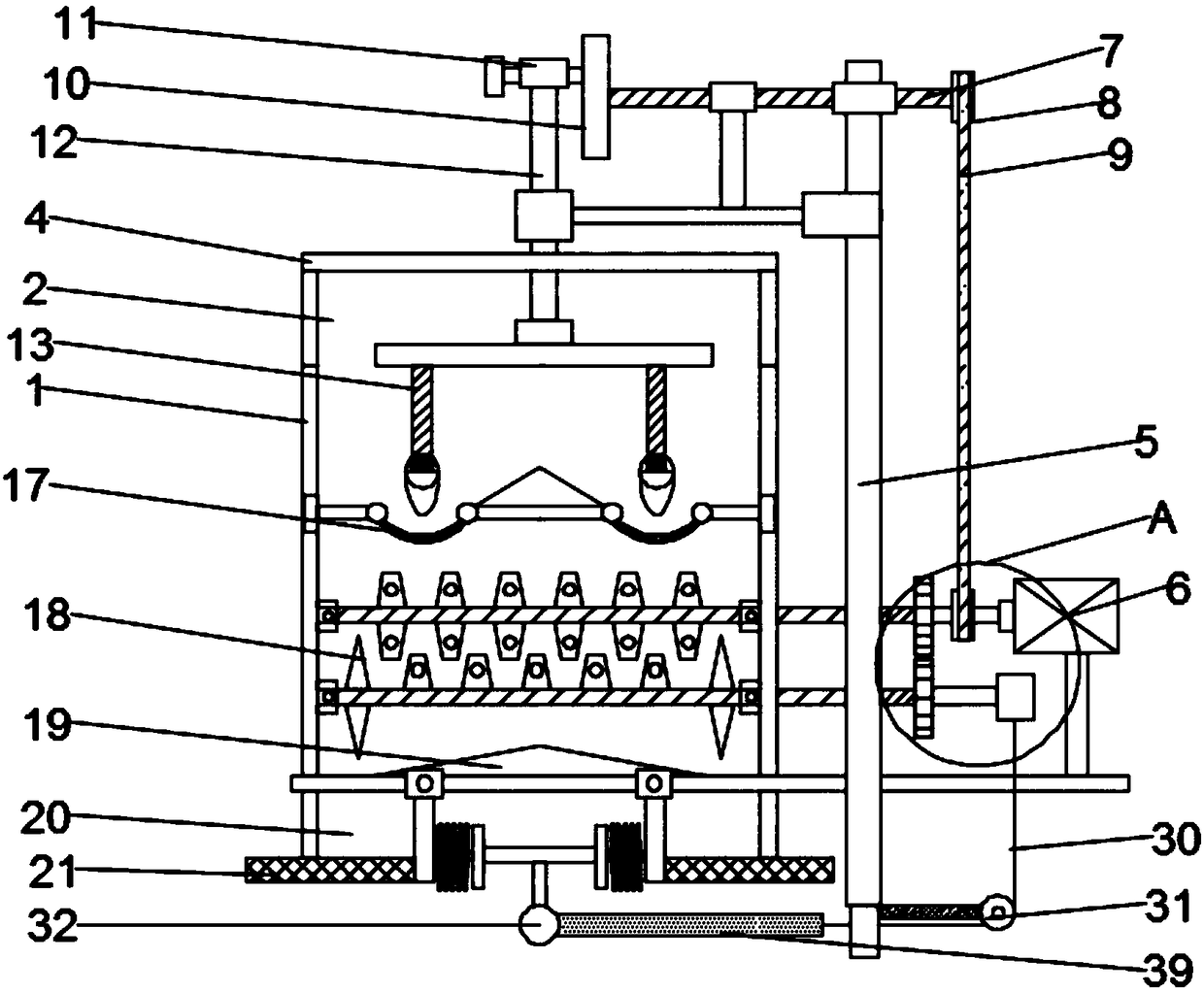

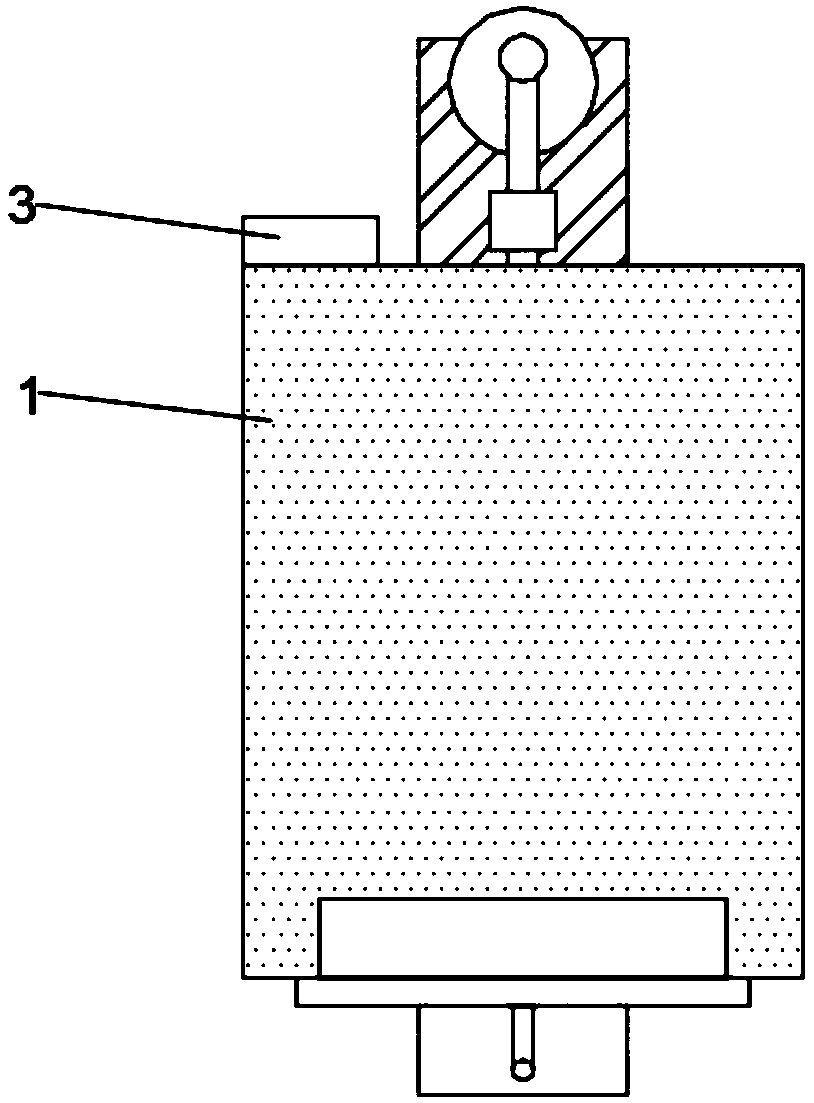

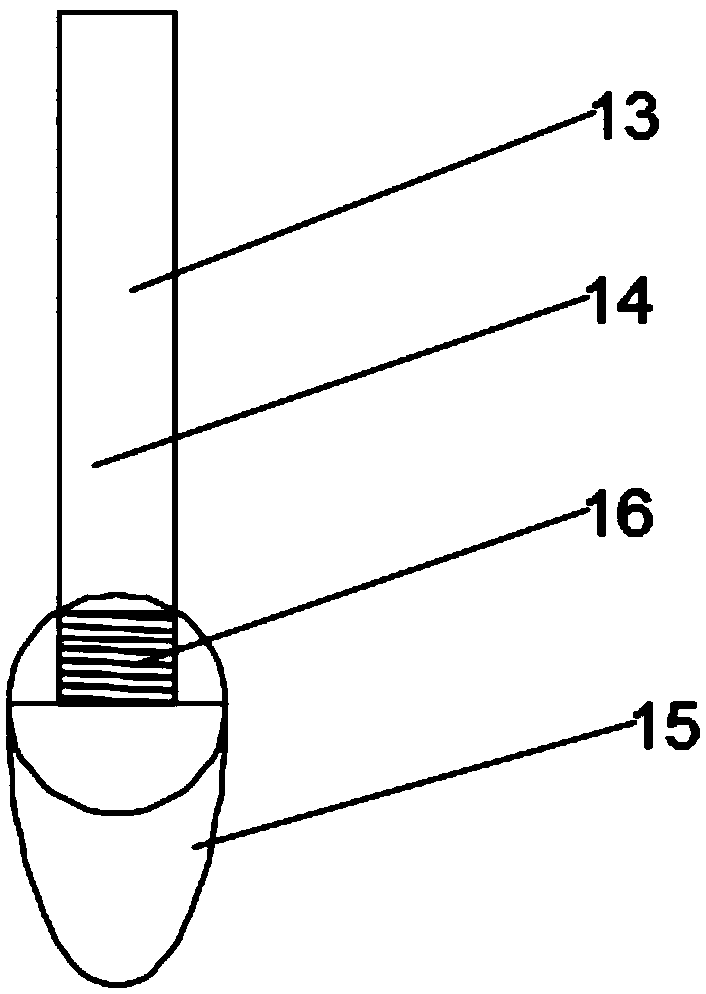

[0028] see Figure 1~6, in an embodiment of the present invention, a waste filter residue crushing device for cement production includes a machine body 1, a crushing chamber 2, a feeding port 3, an upper cover plate 4, a crushing assembly 13, a crushing assembly 18 and a discharge port 20, The right side of the body 1 is vertically provided with a supporting vertical plate 5, the interior of the body 1 is provided with a crushing chamber 2, the upper part of the body 1 is fixedly welded with an upper cover plate 4, and the rear side of the upper surface of the upper cover plate 4 is provided with a feeding port 3 , the feeding port 3 communicates with the crushing chamber 2, two crushing assemblies 13 are symmetrically arranged on the top of the crushing chamber 2, and a crushing assembly 18 is arranged below the crushing assembly 13, and the crushing assembly 18 includes a first The crushing blade 23 and the second crushing blade 25, a deflector 19 is arranged at the middle p...

Embodiment 2

[0034] Such as Figure 7 As shown, the difference from Embodiment 1 is that the lower end of the support vertical plate 5 is fixed with a welded hydraulic cylinder 38, and the telescopic rod on the hydraulic cylinder 38 is hinged with the lower end of the third vertical connecting rod 37, and the hydraulic cylinder The setting of 38 can also serve the purpose of intermittent discharge, and compared with embodiment 1, the setting of the third runner 28 is easier to control the amount of waste slag discharged after crushing.

[0035] The working principle of the present invention is: the waste residue is put into the crushing chamber 2 through the feeding port 3, and the working motor 6 can drive the first runner 8 to rotate by starting the forward and reverse rotation, and the first runner 8 drives the first runner 8. A rotating shaft 7 and the second runner 10 rotate, which can make the second runner 10 drive the lifting rod 12 and the mashing assembly 13 to slide up and down,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com