Ventilation type hog house

A ventilated, pig house technology, applied in the field of livestock and poultry houses, can solve the problems of unguaranteed sanitation conditions, waste residues, unfavorable pig activities, etc., and achieve the effects of comprehensive coverage, prevention of rigid damage, and improvement of ventilation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

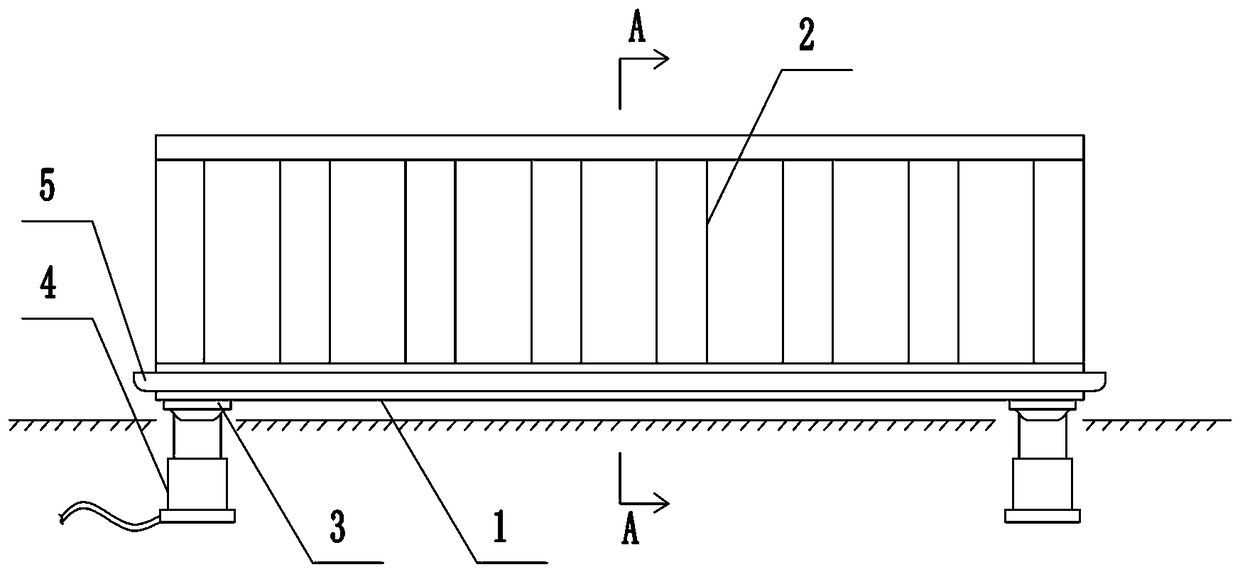

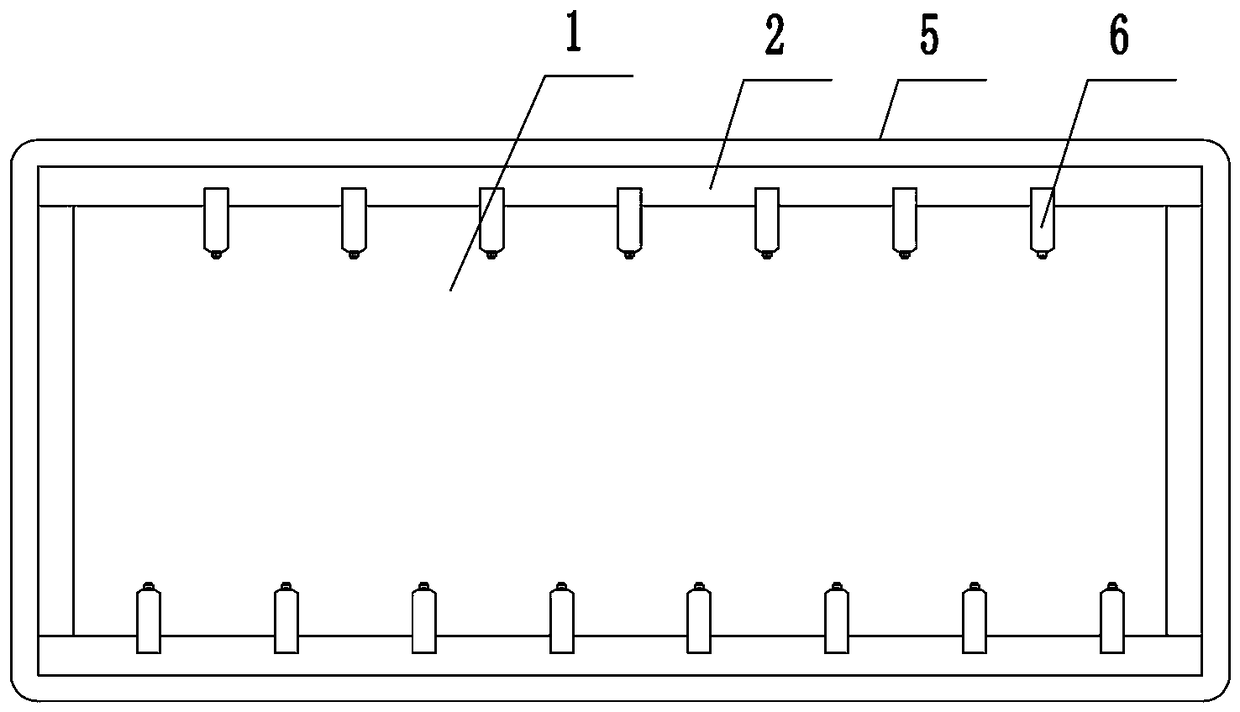

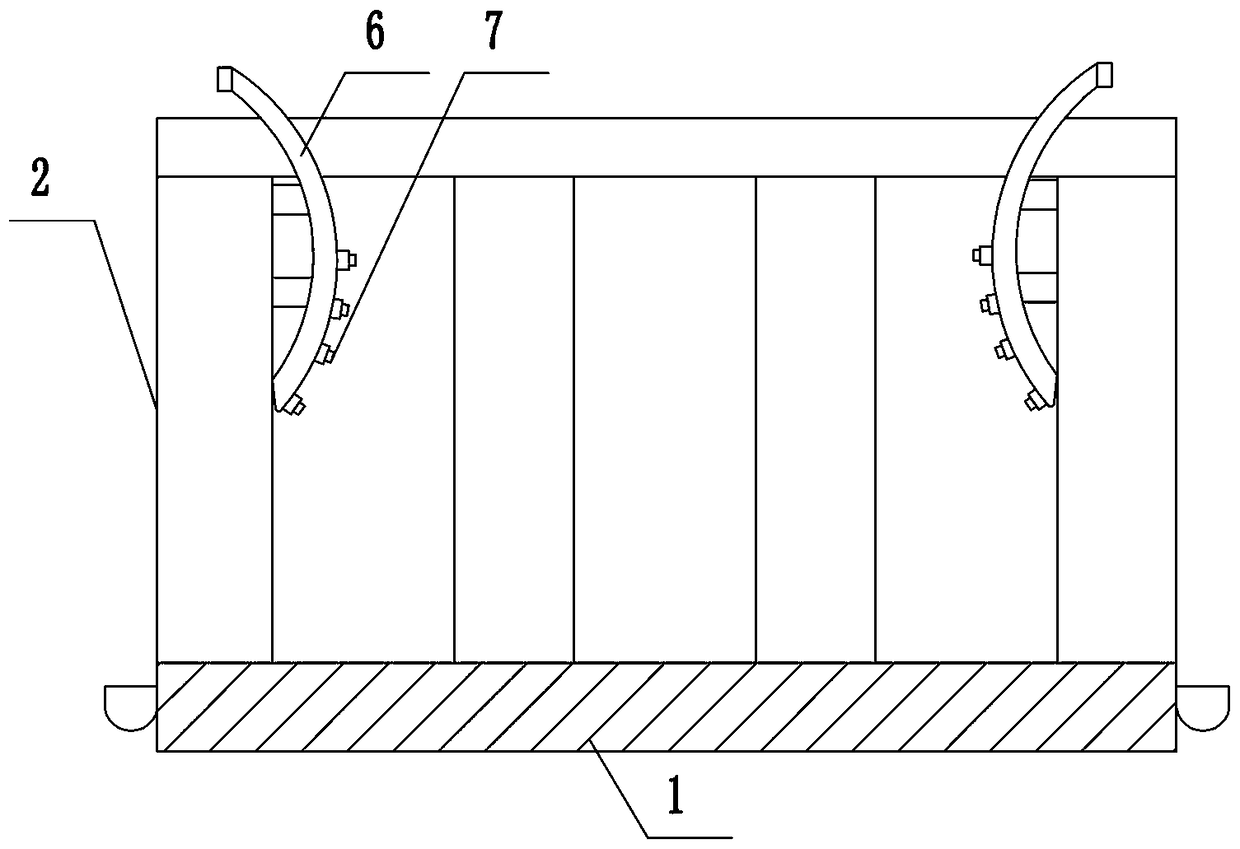

[0033] Such as Figure 1 to Figure 3 As shown, the present invention includes a base plate 1 and a fence 2, the base plate 1 and the fence 2 are welded by steel structure, a plurality of height adjustment mechanisms are arranged on the lower end surface of the base plate 1, and the height adjustment mechanism includes a hydraulic lifting mechanism and a connecting plate 3, a hydraulic pressure The lifting mechanism adopts the hydraulic lifting device of the prior art, including a hydraulic oil tank, an oil pump, a control valve and a telescopic cylinder 4. The base plate 1 is fixedly connected, the edge of the base plate 1 is fixedly provided with a chute 5, and the left and right sides of the fence 2 are provided with spray pipes 6. The spray pipe 6 is designed in an arc shape or inclined. The spray pipes 6 on the left and the spray pipes 6 on the right are arranged alternately in space.

Embodiment 2

[0035] The present invention includes a base plate 1 and a fence 2, the base plate 1 and the fence 2 are welded by steel structure, the lower end surface of the base plate 1 is provided with a plurality of height adjustment mechanisms, the height adjustment mechanism includes a hydraulic lifting mechanism and a connecting plate 3, and the hydraulic lifting mechanism adopts The hydraulic lifting device in the prior art includes a hydraulic oil tank, an oil pump, a control valve and a telescopic cylinder 4. The hydraulic telescopic mechanism is located under the ground, and the connection plate 3 is connected to the upper end of the telescopic cylinder 4 by a ball joint, and the connection plate 3 is fixed to the bottom plate 1. connection, the edge of the bottom plate 1 is fixedly provided with a chute 5, and the left and right sides of the fence 2 are provided with a spray pipe 6, the spray pipe 6 is an arc or inclined design, and a plurality of nozzles 7 are arranged on the spr...

Embodiment 3

[0038]The present invention includes a base plate 1 and a fence 2, the base plate 1 and the fence 2 adopt a steel structure and are plugged and fixed, the lower end surface of the base plate 1 is provided with a plurality of height adjustment mechanisms, and the height adjustment mechanism includes a hydraulic lifting mechanism and a connecting plate 3, a hydraulic lifting mechanism The hydraulic lifting device of the prior art is adopted, including a hydraulic oil tank, an oil pump, a control valve and a telescopic hydraulic cylinder 4. The hydraulic telescopic mechanism is located under the ground. Fixedly connected, the edge of the base plate 1 is fixedly provided with a chute 5, and the left and right sides of the fence 2 are provided with a spray pipe 6. The spray pipe 6 is designed to be curved or inclined. The shower pipe 6 on the right side and the shower pipe 6 on the right side are arranged alternately in space, and the fence 2 is a split structure.

[0039] The stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com