Clamping device for feeding and discharging and robot

A clamping device and chuck technology, applied in the field of loading and unloading clamping devices and robots, can solve the problems of improper installation of the workpiece, no free space for the workpiece, and easy damage to the surface of the workpiece, so as to avoid rigid damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

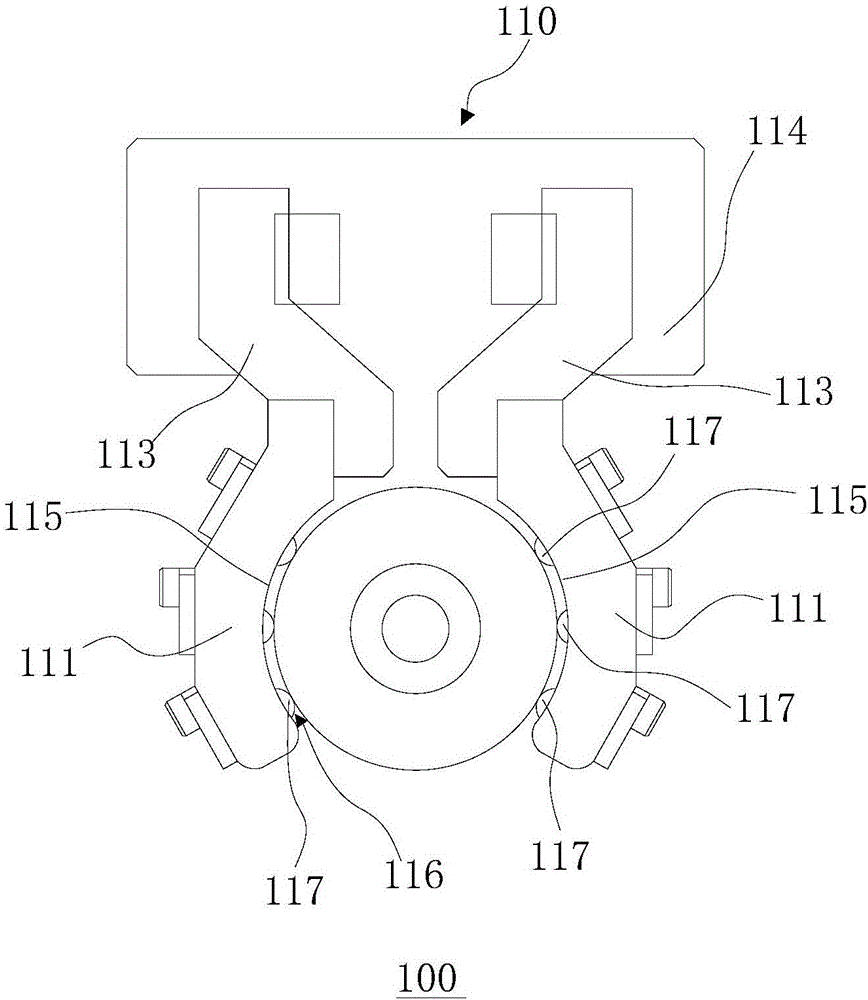

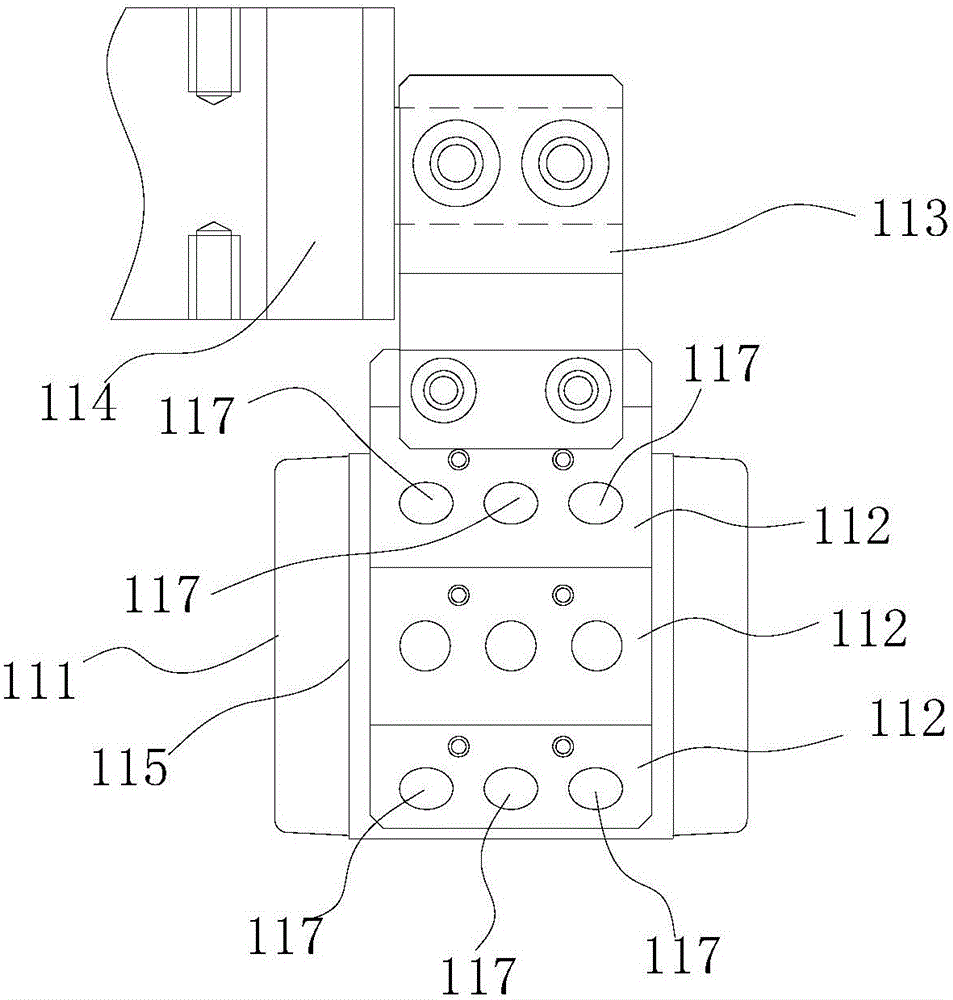

[0033] see Figure 1 ~ Figure 2 , The loading and unloading clamping device 100 provided in this embodiment includes a mounting base and a clamping jaw mechanism 110 for clamping a workpiece. The loading and unloading and clamping device 100 can be installed on various robotic arms through the mounting base.

[0034] Specifically, in this embodiment, the jaw mechanism 110 includes a plurality of chucks 111 , a plurality of connecting arms 113 and a driving device 114 for driving the connecting arms 113 to move. The number of connecting arms 113 corresponds to the number of clips 111 , and the multiple connecting arms 113 are fixedly connected to the multiple clips 111 one by one. Wherein, the driving device 114 is installed on the mounting base. Of course, the number of driving devices 114 corresponds to the number of connecting arms 113 . Preferably, in this embodiment, the driving device 114 is an air cylinder, and the connecting arm 113 is connected with the piston of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com