Plate sorting and conveying device

A conveying device and plate technology, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of low degree of automation, easy falling of plates, waste of labor, etc., so as to avoid rigid damage, fast transportation, and improve work efficiency. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

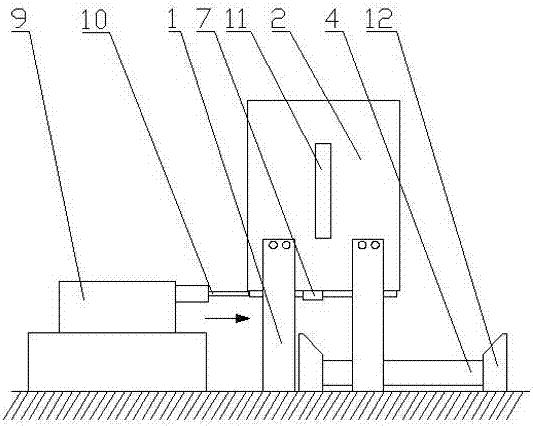

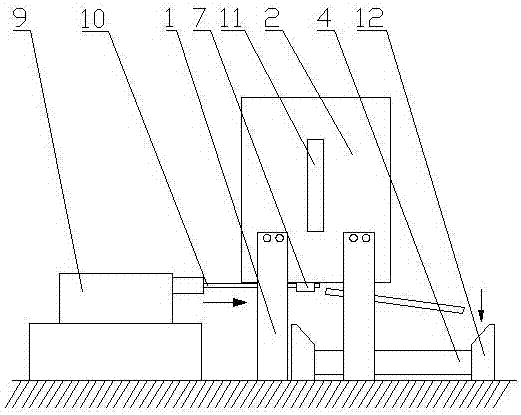

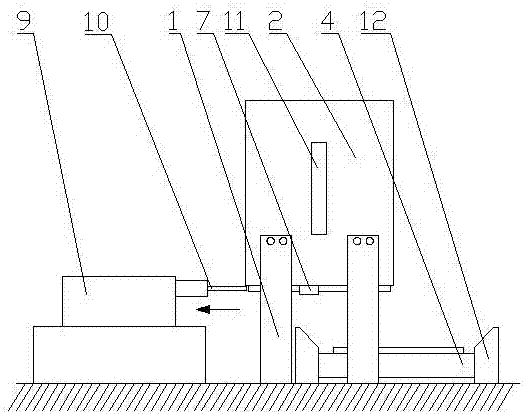

[0035] Such as figure 1 , 2 , 3 and 4, the plate sorting transmission device includes a bracket 1, a material box 2, a discharge device and a guide rail 4, the material box 2 is supported by the bracket 1, and the top of the material box 2 is provided with a feeding port. There is a discharge port 6 at the bottom, and a baffle 7 extends downward along the bottom edge of the outer wall of the material box 2. The bottom end of the baffle plate 7 extends horizontally toward the inner side of the material box 2 with a clamping plate 8, and the clamping plate 8 and A plate guide cavity is formed between the discharge ports 6; a plate horizontal push rod 10 that can push the plate to be pushed out of the plate guide cavity is arranged in the plate guide cavity, and the piston of the cylinder 9 is fixedly connected with the plate horizontal push rod 10. The distance between the clamping plate 8 and the feed port is equal to the thickness of the plate to be pushed out, and the plate ...

Embodiment 2

[0037] Such as figure 1 , 2 As shown in and 3, compared with Example 1, this embodiment optimizes the plate horizontal push rod 10, the baffle plate 7 and the clamping plate 8 constitute a fixed claw to prevent the plate from falling, and there are two fixed claws, which are respectively arranged on the material placement A set of opposite outer wall bottoms on the box 2, in this embodiment, the two fixing claws can hold the plate more stably and prevent the plate from falling.

Embodiment 3

[0039] Compared with Example 1, this embodiment optimizes the clamping plate 8, and the plate horizontal push rod 10 is located between the two fixed claws in the vertical direction. In this embodiment, when the plate horizontal push rod 10 is prevented from pushing the plate, the plate will The horizontal push rod 10 and the fixed claw touch each other, thereby damaging the plank horizontal push rod 10 or the fixed claw.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com