Constitutive model of welded joints based on nanoindentation test

A technology of welded joints and constitutive models, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of difficult sampling of joint micro-areas and high test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

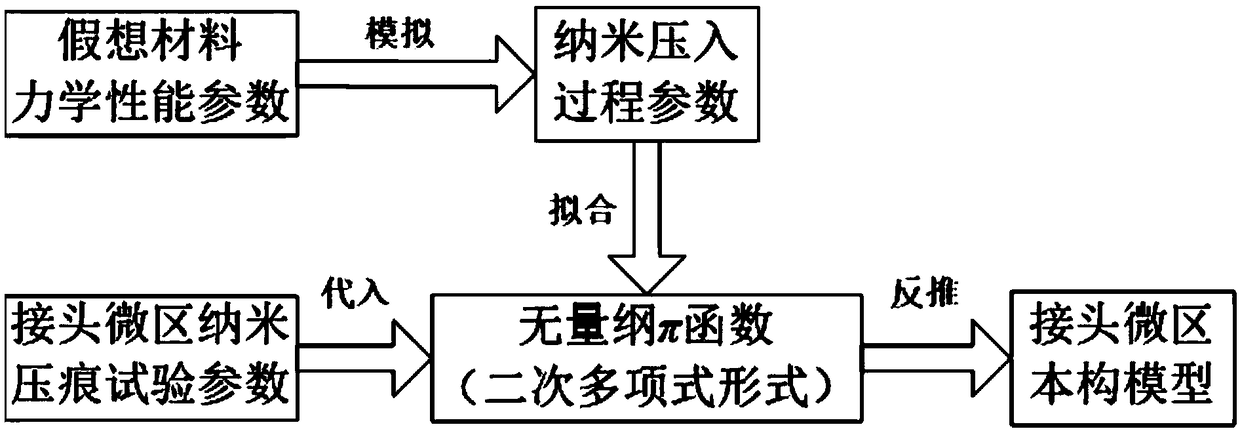

[0055] Such as figure 1 As shown, a method for inversion of constitutive model of welded joints based on nanoindentation test, including the following steps:

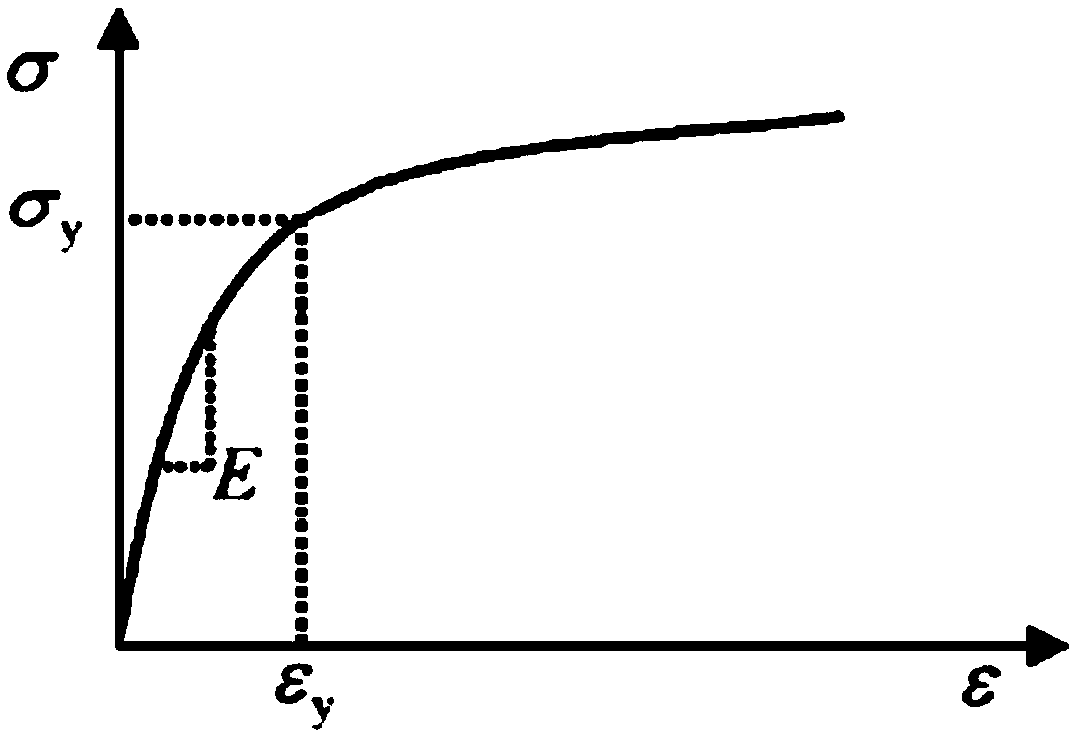

[0056] Step 1: Determine the constitutive model that the welded joint conforms to, and construct the mathematical expression of the constitutive model expressed by the mechanical property parameters of the material;

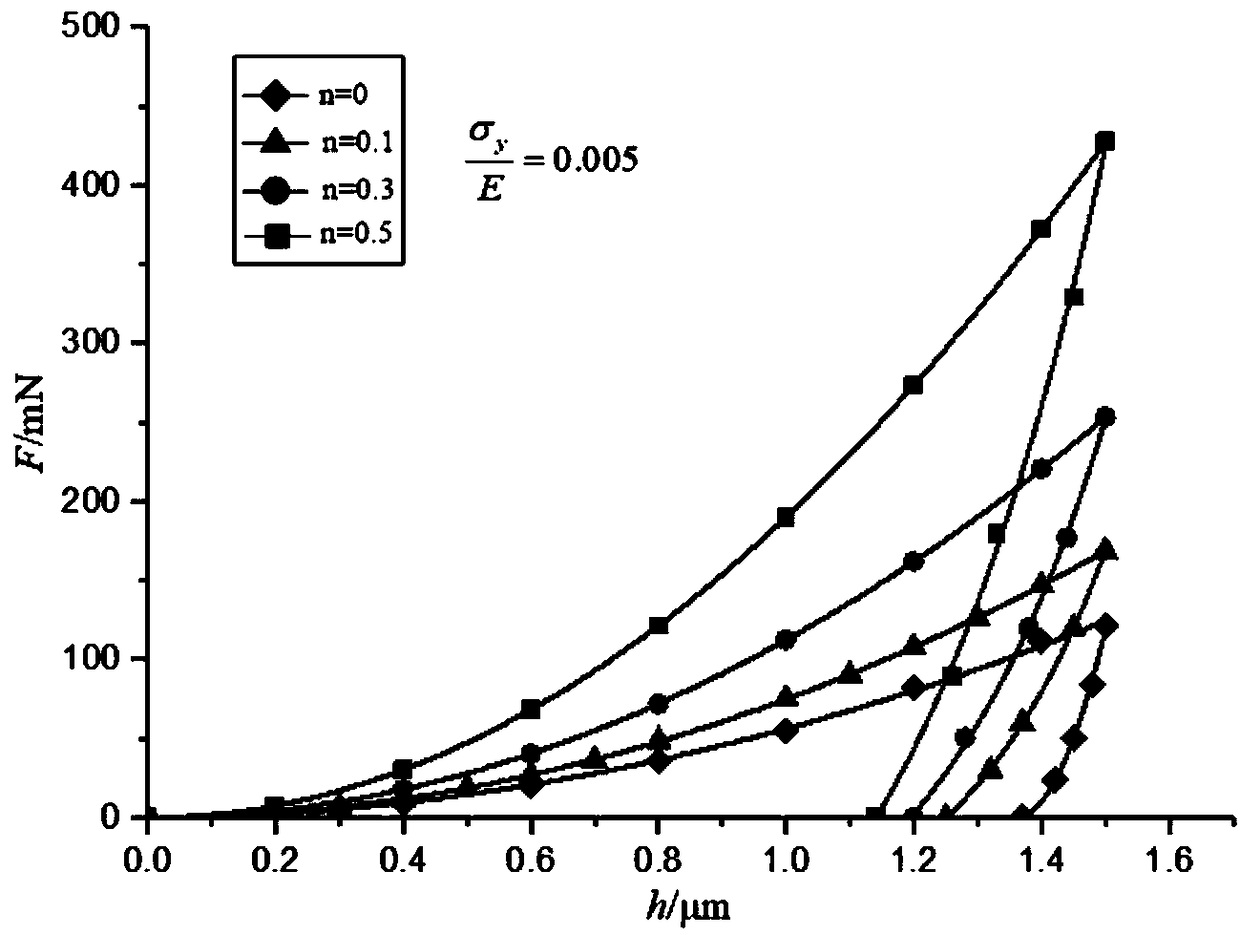

[0057] Step 2: Use the π theorem to conduct a dimensional analysis on the process of the indenter pressing into the surface of the welded joint, and derive the dimensionless π function relationship between the basic mechanical property parameters of the material during the loading / unloading process and the indenter pressing process parameters;

[0058]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com