Folding device for shirt

A technology for folders and shirts, applied in the field of folders, can solve the problems of uneven folding, inability to absorb shirts, poor folding effect, etc., and achieve the effect of easy removal of shirts and good folding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

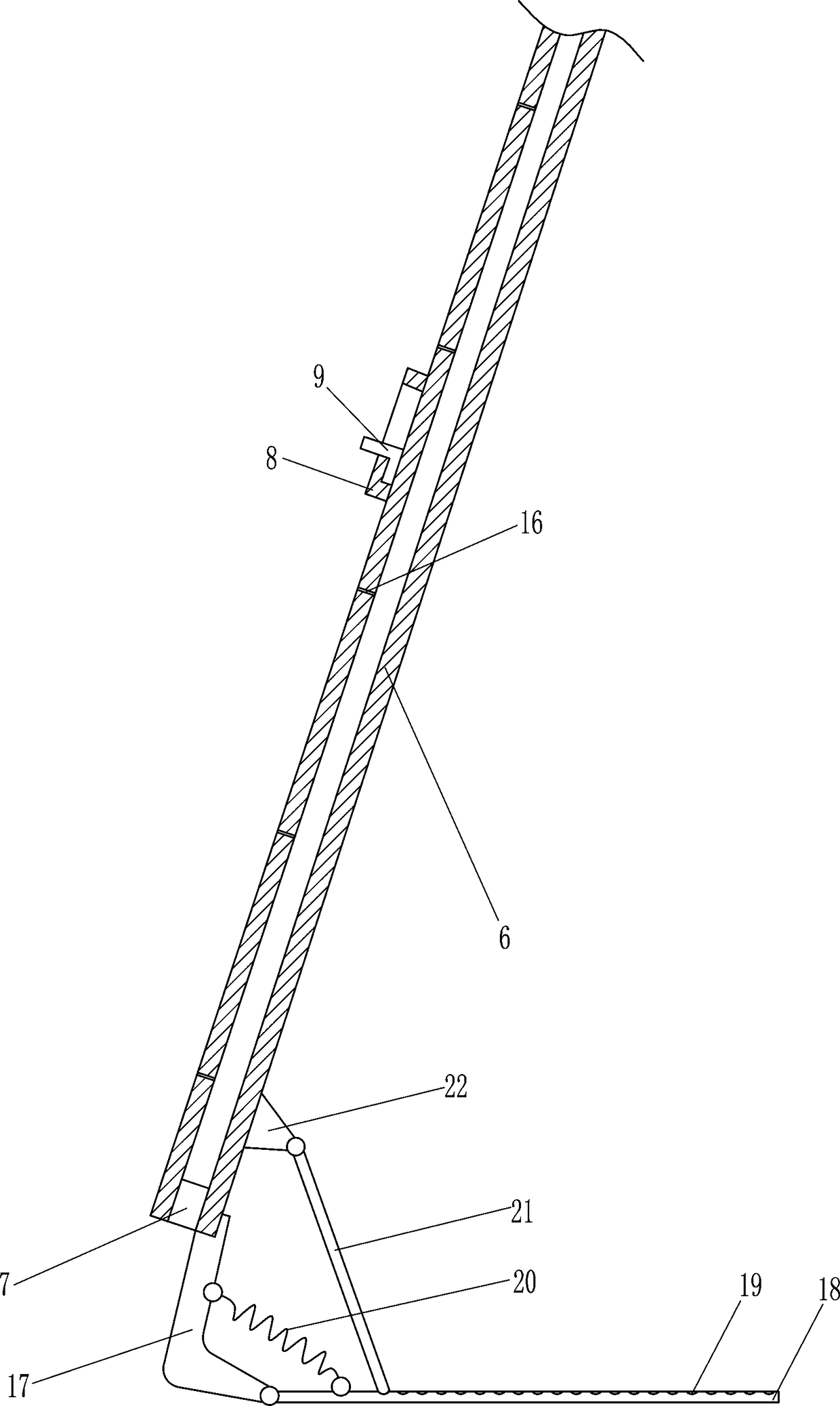

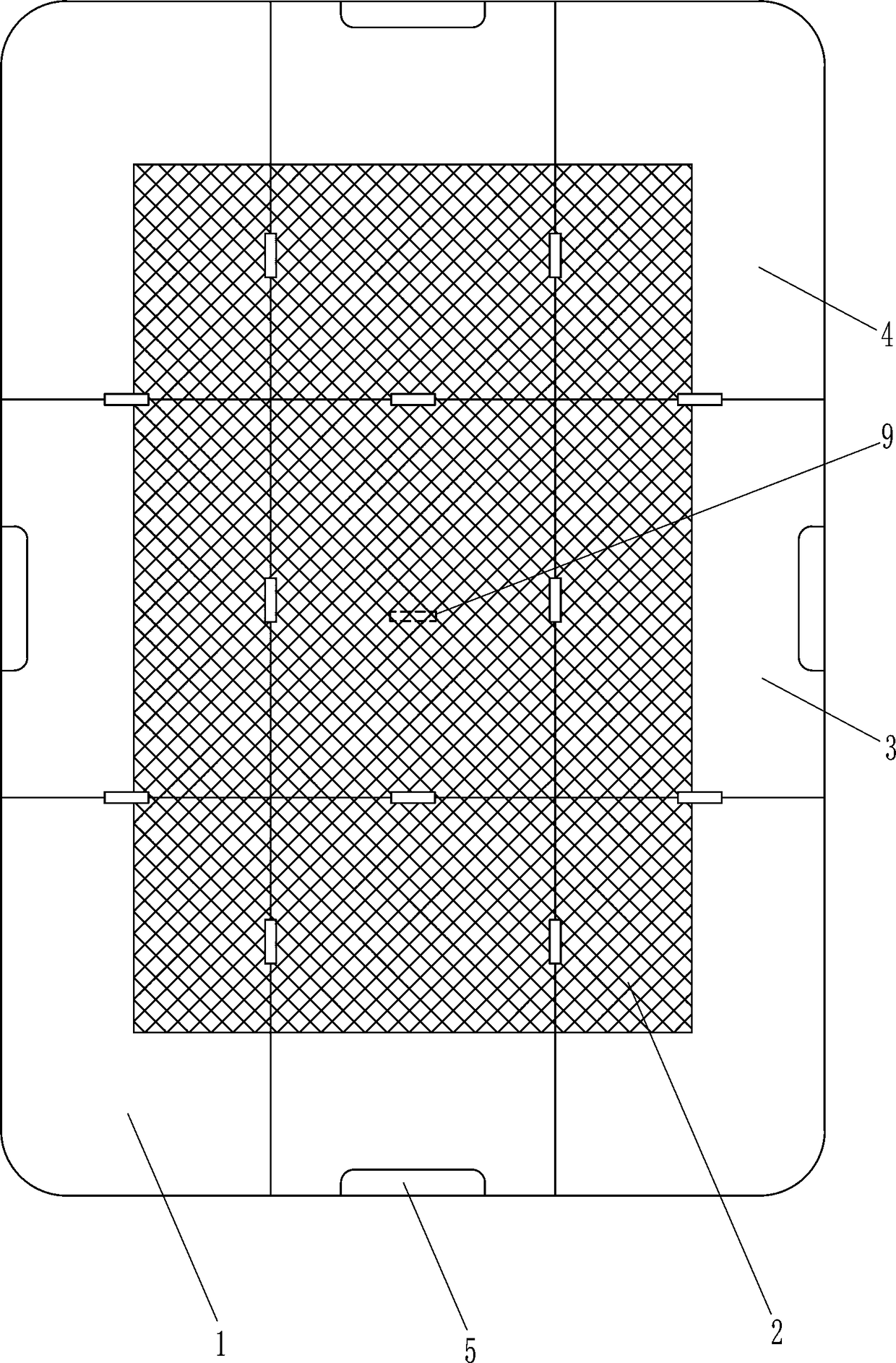

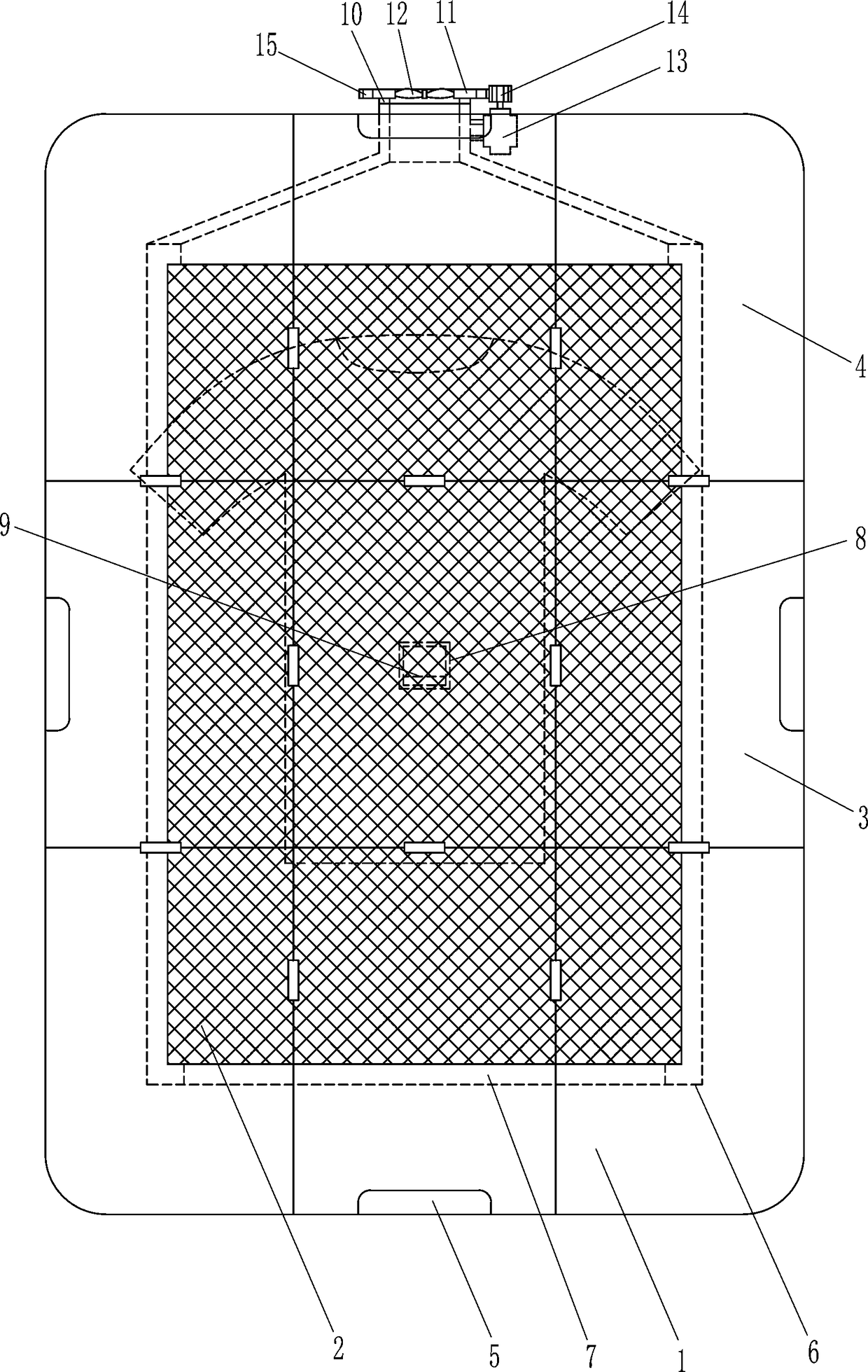

[0022] A shirt folder such as Figure 1-6 As shown, it includes a first placement board 1, a protective net 2, a second placement board 3, a third placement board 4, an air suction frame 6, a placement frame 8, a first fixed block 9, an annular slide rail 10, and a slider 11 , fan blade 12, motor 13, first gear 14 and ring gear 15, three first placement plates 1 are connected in a rotational manner, the rear side of the first placement plate 1 is rotatably connected with a second placement plate 3, and the three first placement plates Rotational connection between the two placing plates 3, the second placing plate 3 rear side is rotationally connected with the third placing plate 4, the three third placing plates 4 are rotationally connected, the first placing plate 1, the second placing plate 3 and the third placement plate 4 are embedded with a protective net 2, nine protective nets 2 are spliced together, the middle of the first placement plate 1 front side middle part, t...

Embodiment 2

[0024] A shirt folder such as Figure 1-6 As shown, it includes a first placement board 1, a protective net 2, a second placement board 3, a third placement board 4, an air suction frame 6, a placement frame 8, a first fixed block 9, an annular slide rail 10, and a slider 11 , fan blade 12, motor 13, first gear 14 and ring gear 15, three first placement plates 1 are connected in a rotational manner, the rear side of the first placement plate 1 is rotatably connected with a second placement plate 3, and the three first placement plates Rotational connection between the two placing plates 3, the second placing plate 3 rear side is rotationally connected with the third placing plate 4, the three third placing plates 4 are rotationally connected, the first placing plate 1, the second placing plate 3 and the third placement plate 4 are embedded with a protective net 2, nine protective nets 2 are spliced together, the middle of the first placement plate 1 front side middle part, t...

Embodiment 3

[0027] A shirt folder such as Figure 1-6As shown, it includes a first placement board 1, a protective net 2, a second placement board 3, a third placement board 4, an air suction frame 6, a placement frame 8, a first fixed block 9, an annular slide rail 10, and a slider 11 , fan blade 12, motor 13, first gear 14 and ring gear 15, three first placement plates 1 are connected in a rotational manner, the rear side of the first placement plate 1 is rotatably connected with a second placement plate 3, and the three first placement plates Rotational connection between the two placing plates 3, the second placing plate 3 rear side is rotationally connected with the third placing plate 4, the three third placing plates 4 are rotationally connected, the first placing plate 1, the second placing plate 3 and the third placement plate 4 are embedded with a protective net 2, nine protective nets 2 are spliced together, the middle of the first placement plate 1 front side middle part, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com