Heat transmission spiral heat dissipation handle

A heat transfer and handle technology, applied in the field of heat transfer spiral heat dissipation handle, can solve the problems of cyclist's hand slipping, handle falling off, cyclist's palm sweating, etc., to improve heat absorption and cooling efficiency, improve safety, and improve friction. The effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

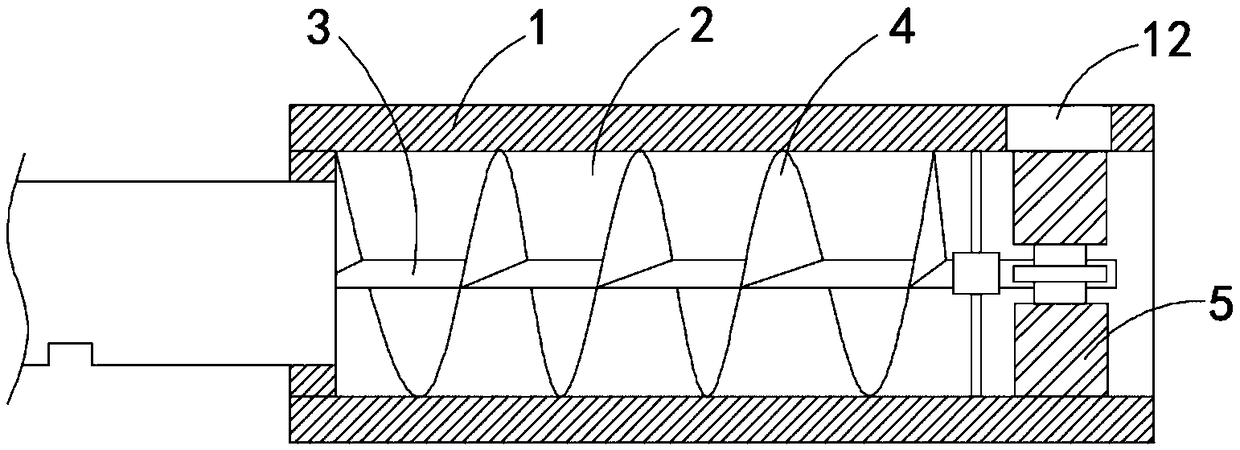

[0023] Such as Figure 1-2 As shown, a heat transfer spiral heat dissipation handle includes a handle body 1. The handle body 1 is made of a material with good thermal conductivity such as stainless steel to improve heat conduction efficiency. The rotating shaft 3 is connected in rotation, and a bearing is sleeved on the rotating shaft 3. The outer ring of the bearing is fixedly connected with the inner wall of the heat conducting chamber 2 through a plurality of connecting rods, and the rotating shaft 3 is rotationally connected with the inner wall of the heat conducting chamber 2 through the bearing. The helical blade 4 is fixedly connected, and the outer contour of the helical blade 4 is sealed and slid with the side wall of the heat conduction chamber 2 to ensure the one-way delivery of the airflow in the heat conduction chamber 2. One end of the rotating shaft 3 extends outside the heat conduction chamber 2 and is coaxial A plurality of fan blades 5 are fixedly connected,...

Embodiment 2

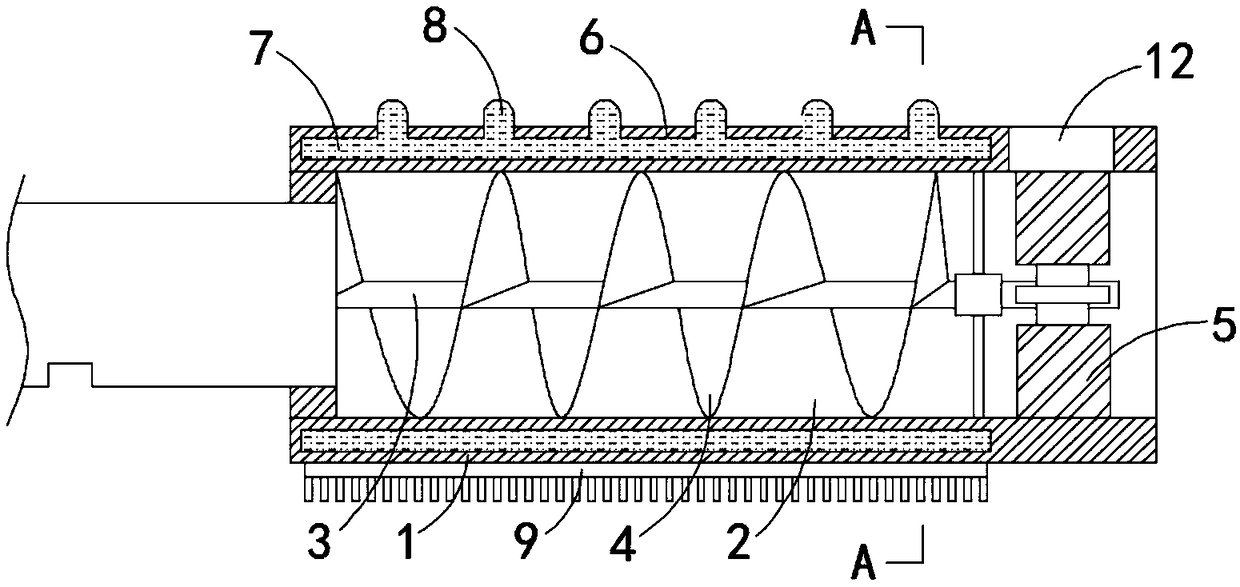

[0026] Such as Figure 3-5 As shown, the difference between this embodiment and Embodiment 1 is that: the handle body 1 is provided with an annular cavity 6, and the annular cavity 6 is filled with a cooling liquid 7, and the cooling liquid 7 can be water or has a larger specific heat capacity than water. The upper end of the handle body 1 is fixedly connected with a plurality of elastic liquid storage bags 8, the elastic liquid storage bags 8 can be made of materials such as silica gel or rubber, and the elastic liquid storage bags 8 are arc-shaped, which is easy to hold, and the elastic liquid storage bags 8 Connected with the annular cavity 6, the lower end of the handle body 1 is fixedly connected with a cooling fin 9, and the lower surface of the cooling fin 9 is fixedly connected with a plurality of cooling fins, and the extending direction of the cooling groove formed between adjacent cooling fins is the same as The riding direction is parallel, so that the wind can qui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com