Large-angle turning device of belt conveyor

A technology of belt conveyor and turning device, which is used in transportation and packaging, conveyors, conveyor objects, etc., can solve problems such as heat damage, material throwing, and inability to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

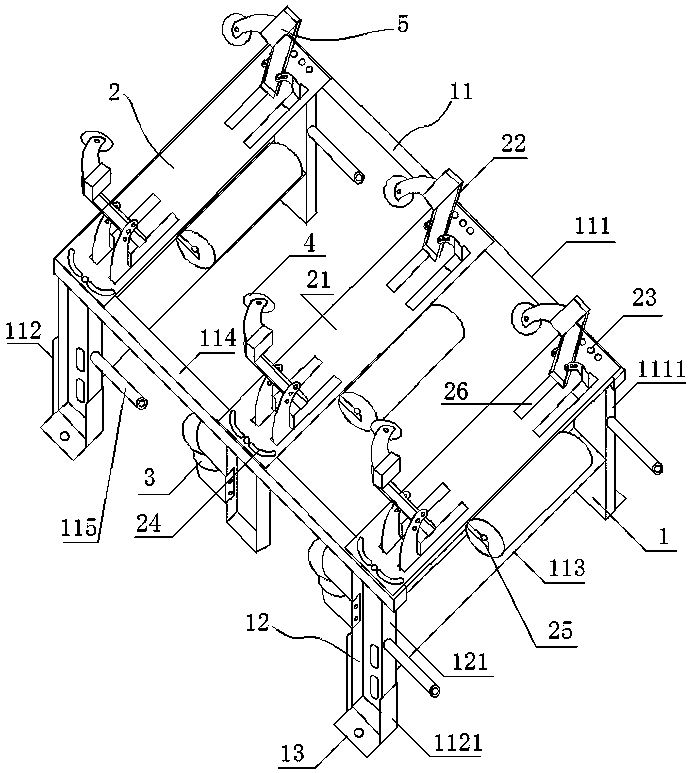

[0019] Such as figure 1 As shown, a large-angle turning device of a belt conveyor is composed of a plurality of turning units. The turning unit includes an underframe mechanism 1 and an idler mechanism 2. The underframe mechanism 1 includes a base frame 11 and an adjustment frame. 12. The adjustment frame 12 is installed on one side of the base frame 11; the roller mechanism 2 includes an end face mounting frame 21, one end of the end face mounting frame 21 is installed on the uppermost end surface of the base frame 11, and the other end is installed on the adjustment frame 12 On the uppermost end face, adjustment units are arranged on the corresponding installation surfaces of the roller mechanism 2, the base frame 11, and the adjustment frame 12; the roller mechanism 2 also includes a side roller frame 22 and a main roller frame 25, two The side roller frames 22 are respectively installed on both sides of the end surface mounting frame 21 close to the base frame 11 and the a...

Embodiment 2

[0024] As an optimized design for Example 1, the base frame 11 at least includes a height-fixing frame 111 on one side, an adjustment mounting frame 112 on the other side, and several connecting rods 113 connecting the height-fixing frame 111 and the adjustment mounting frame 112 .

[0025] The height-fixing frame 111 is composed of at least two height-fixing legs 1111, the end beams 114 connecting the two height-fixing legs 1111, the fixed plate 13 arranged on the lower end surface of the height-fixing legs 1111, and the return idlers installed on the height-fixing legs 1111 A set of mounting rods 115; the adjustment mounting frame 112 includes at least two slot legs 1121, and the fixing plate 13 is installed on the lower end surface of the slot legs 1121; the connecting rod 113 connects the height-fixing legs 1111 and the slot legs 1121.

[0026] The adjustment frame 12 includes two adjustment slot legs 121, the end beam 114 connecting the two adjustment slot legs 121, and t...

Embodiment 3

[0028] As an optimized design for Example 1, the side roller frame 22 includes a pair of side roller fixing ear frames and a side roller fixing frame, and several installation holes are arranged on the two side roller fixing ear frames, The fixed frame of the side roller is fixed through the mounting holes, and the angle with the end mounting frame is adjusted through different mounting holes.

[0029] An arc-shaped upper limit adjustment frame is installed on the side idler frame 22, and an adjustment wheel is installed on the upper limit adjustment frame.

[0030] After the position between the two side roller frames is adjusted, it is sometimes necessary to adjust the angle of the side rollers. Therefore, a side roller fixing ear frame with several mounting holes is designed to realize the angle adjustment of the side roller fixing frame.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com