Sealing detection device for camshaft front end cover, and detection method

A technology of sealing detection and detection device, which is applied in the direction of measurement device, fluid tightness test, machine/structural component test, etc. To achieve the effect of short detection time, accurate detection, and avoidance of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to facilitate those skilled in the art to understand the technical solution of the present invention, the technical solution of the present invention will be further described in conjunction with the accompanying drawings.

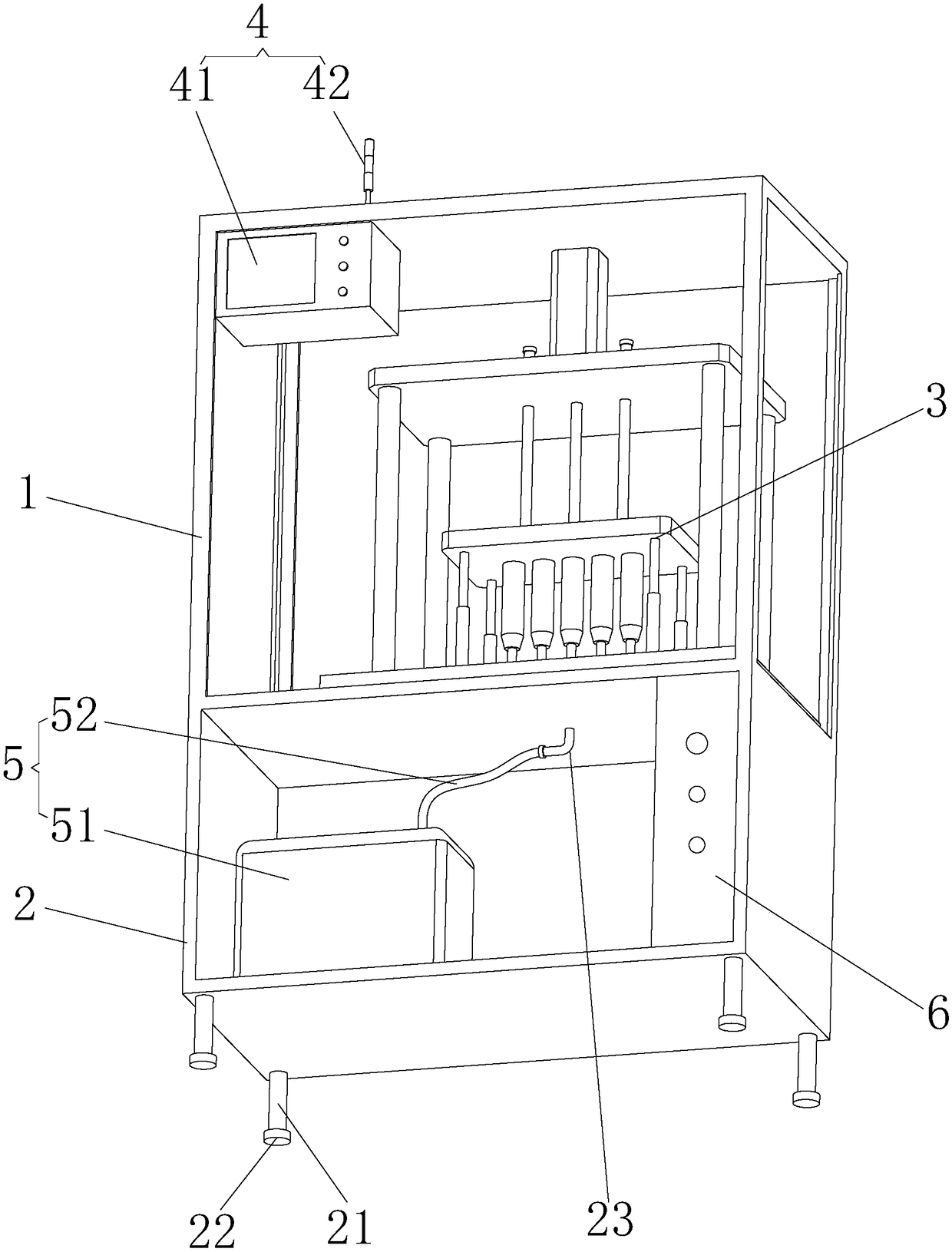

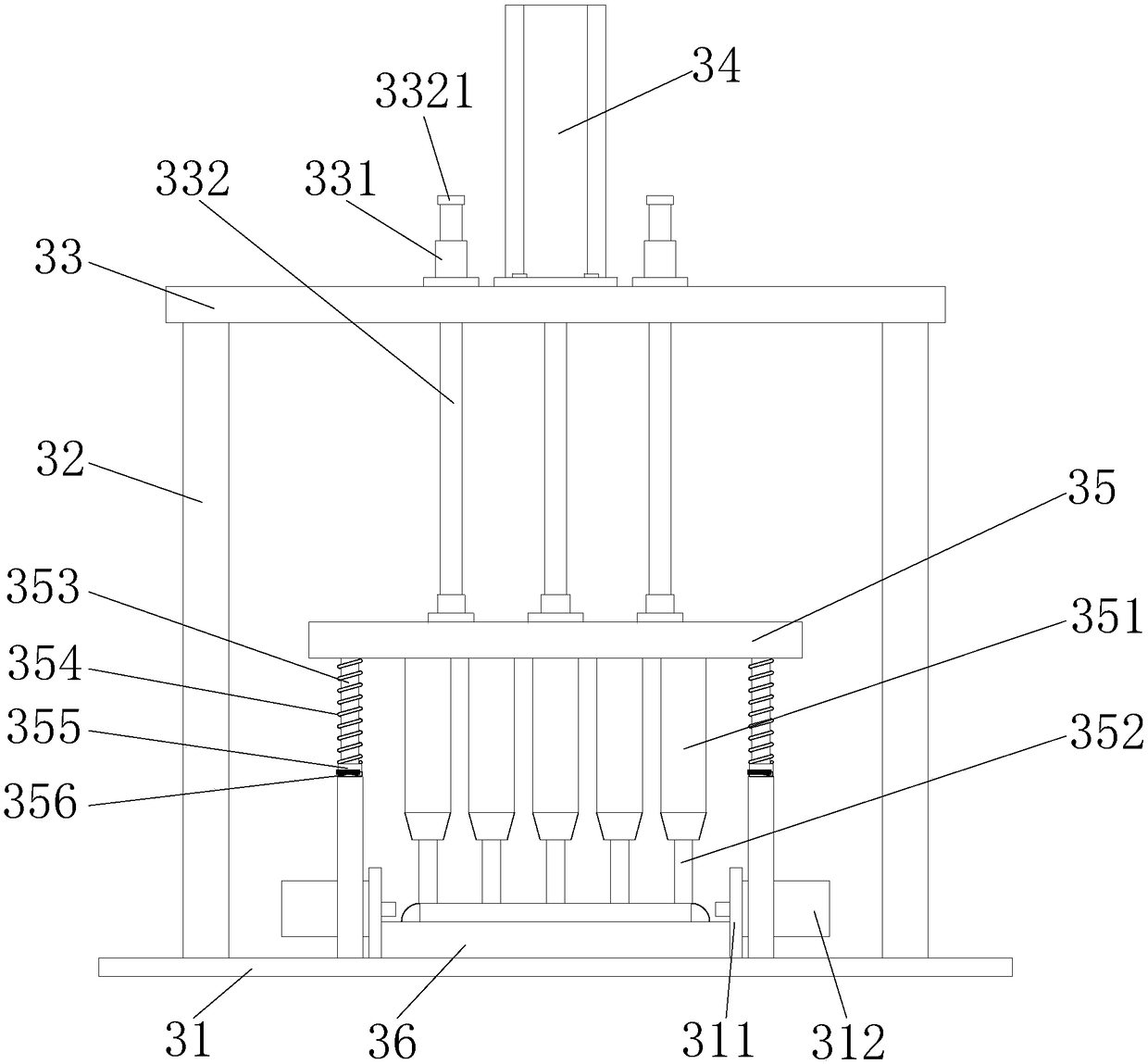

[0029] refer to Figure 1 to Figure 2 , this embodiment discloses a seal detection device at the end of the camshaft front cover, including a first housing 1, a second housing 2, a blocking device 3, a detection device 4, a ventilation device 5 and a control panel 6; A casing 1 is fixed on the second casing 2, the surroundings of the first casing 1 are transparent in the front, rear, left, and right sides, and the front and rear sides of the second casing 2 are transparent. The ground of the bottom plate of the body 2 is fixed with four legs 21, and the legs 21 are respectively distributed along the directions of the four corners of the bottom plate of the second housing 2, and the bottom surface of the legs 21 is fixed with a rubber gasket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com