A kind of sodium alginate/pineapple pomace nano-cellulose blended drug film and its preparation method and application

A technology of nano-cellulose and pineapple skin dregs, which is applied in the fields of pharmaceutical formulations, drug delivery, and medical preparations of non-active ingredients, etc., to achieve the effects of mild reaction conditions, simple process operation, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Wash the pineapple peels until the water is transparent and crush the pineapple peels, use a filter cloth to separate the pineapple peels from the juice, then wash the pineapple peels until they are transparent, then dry them at 60°C for later use. Mix 50 g of cleaned pineapple skin dregs with 1 L of water, bathe in 75°C for 2 hours, filter the skin dregs with a filter cloth, clean them, add 7.5wt% sodium chlorite solution with pH 3.8, and bleach in a water bath at 75°C for 2 hours , then wash the skin dregs with clear water until white, then wash with 95wt% ethanol and dry. Finally, the dried sample was added to 10wt% NaOH solution for alkalization for 10 h, washed and dried, and crushed to obtain pineapple pomace cellulose (PPC).

[0037] (2) Mix pineapple pomace cellulose with 64% (w / w) sulfuric acid solution according to the ratio of solid to liquid 1:15 (g / mL), stir in a water bath at 45°C for 1.5h, and then use 10 times the volume of distilled water Added to ...

Embodiment 2

[0040] (1) Wash the pineapple peels until the water is transparent and crush the pineapple peels, use a filter cloth to separate the pineapple peels from the juice, then wash the pineapple peels until they are transparent, then dry them at 60°C for later use. Mix 50 g of the cleaned pineapple skin dregs with 750 mL of water, bathe in 70° C. for 3 h, filter the skin dregs with a filter cloth, and clean them up. Add 8 wt % sodium chlorite solution with pH 3.9 and bleach it in a water bath at 80° C. for 4 h. Afterwards, wash the skin dregs with clear water until white, and then dry them with 95% ethanol after washing. Finally, the dried sample was added to 12wt% NaOH solution for alkalization for 10 h, washed and dried, and crushed to obtain pineapple pomace cellulose (PPC).

[0041](2) Mix pineapple pomace cellulose with 64% (w / w) sulfuric acid solution according to the ratio of solid to liquid: 1:17.5 (g / mL), stir in a water bath at 47.5°C for 1.75h, and then use 10 times the v...

Embodiment 3

[0045] (1) Wash the pineapple peels until the water is transparent and crush the pineapple peels, use a filter cloth to separate the pineapple peels from the juice, then wash the pineapple peels until they are transparent, then dry them at 60°C for later use. Mix 50 g of cleaned pineapple skin dregs with 1100 mL of water, bathe in water at 80°C for 2.5 hours, filter the skin dregs with a filter cloth, clean them, add 7.75wt% sodium chlorite solution with pH 4.0, and bleach in a water bath at 70°C After 3 hours, wash the dregs with clean water until white, then wash with 95wt% ethanol and dry. Finally, the dried sample was added to 11wt% NaOH solution for alkalization for 10 h, washed and dried, and crushed to obtain pineapple pomace cellulose (PPC).

[0046] (2) Mix pineapple pomace cellulose with 64% (w / w) sulfuric acid solution according to the ratio of solid to liquid 1:20 (g / mL), stir in a water bath at 50°C for 2 hours, and then add 10 times the volume of distilled water ...

PUM

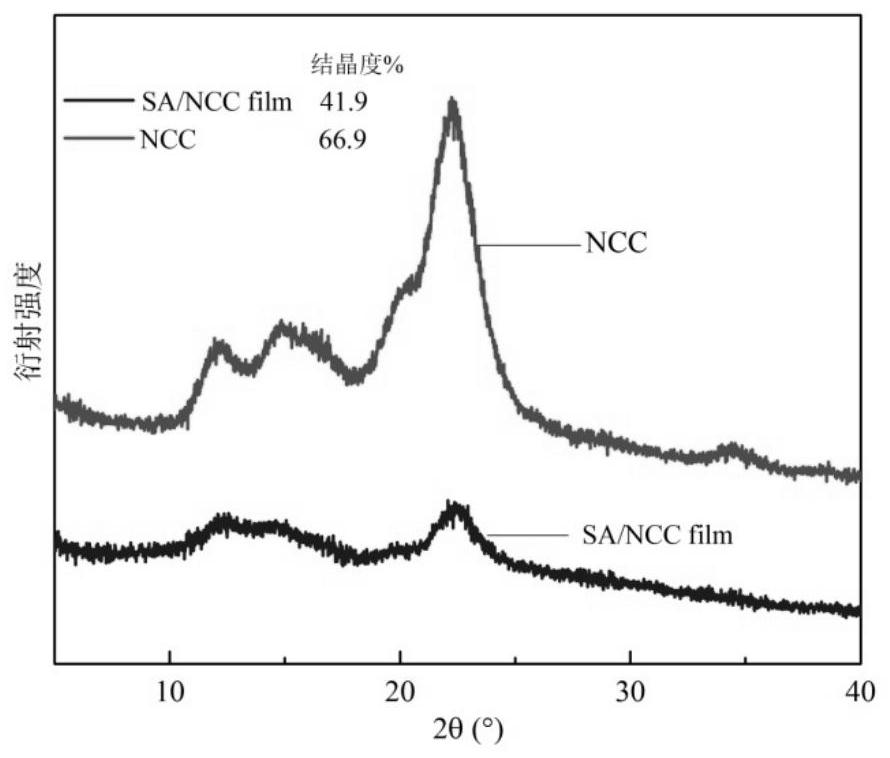

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com