A Passivated Metal Electrode Based on Oxygen-Metal Battery

A metal battery and metal passivation technology, applied in battery electrodes, fuel cell half-cells, primary battery half-cells, circuits, etc., can solve problems such as passivation of metal electrodes, and achieve finer grains and alloys The effect of homogenizing the composition and reducing the amount of hydrogen evolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

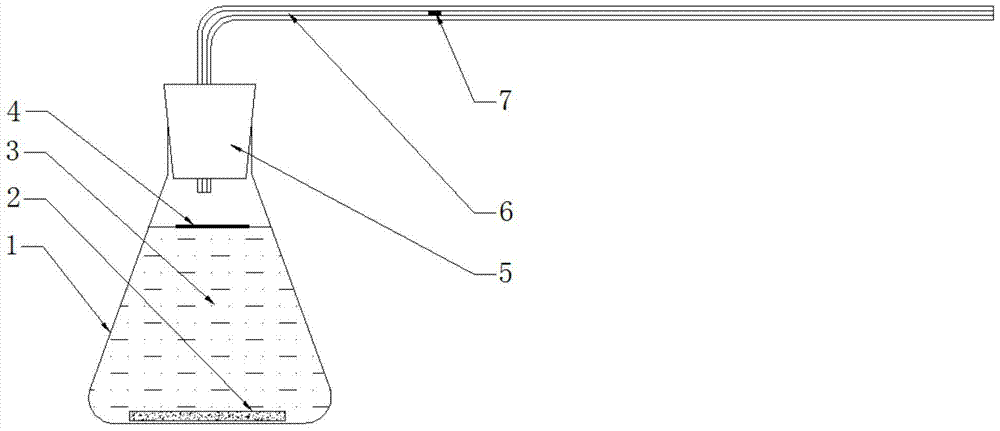

Image

Examples

Embodiment 1

[0030] Embodiment 1: the passivation effect of adding Zr element to Al

Embodiment approach

[0031] In this embodiment, the selected additive element is Zr, and the nominal composition is determined to be Al:Zr=9:1 (atomic ratio), that is, Al 90 Zr 10 , the implementation method is as follows:

[0032] ● Preparation:

[0033] Step 1: Ingredients

[0034] Press Al 90 Zr 10 The nominal composition weighs each elemental element and becomes the raw material for preparing the master alloy ingot.

[0035] Step 2: Smelting

[0036] Put the weighed Zr and Al elements into the copper crucible of the vacuum arc melting furnace for melting.

[0037] The smelting conditions are: the vacuum degree in the vacuum arc melting furnace during smelting is 8×10 -3 Below Pa, fill with 0.5Mpa high-purity argon, smelt for 1-2 minutes each time, and smelt for 3-4 times.

[0038] Step Three: Spray Casting

[0039] Put the master alloy obtained in step 2 into a vacuum induction metal melt rapid cooling solidification furnace (rapid solidification technology), spray it into a metal mol...

Embodiment 2

[0051] Embodiment 2: add Cr element to the passivation effect of Fe

[0052] In the present embodiment, the selected added element is Cr, and the nominal composition is determined to be Fe:Cr=9:1 (atomic ratio), that is, Fe 90 Cr 10 , the implementation method is as follows:

[0053] ● Preparation:

[0054] Step 1: Ingredients

[0055] Press Fe 90 Cr 10 The nominal composition weighs each elemental element and becomes the raw material for preparing the master alloy ingot.

[0056] Step 2: Smelting

[0057] Put the weighed Fe and Cr elements into the copper crucible of the vacuum arc melting furnace for melting.

[0058] The smelting conditions are: the vacuum degree in the vacuum arc melting furnace during smelting is 8×10 -3 Below Pa, fill with 0.5Mpa high-purity argon, smelt for 1-2 minutes each time, and smelt for 3-4 times.

[0059] Step Three: Spray Casting

[0060] Put the master alloy obtained in step 2 into a vacuum induction metal melt rapid cooling solidifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com