Pipe fitting spacer press riveting device

A technology of pipe fittings and spacers, applied in the field of automatic assembly equipment, can solve problems such as easy deformation, and achieve stable and reliable results in the completion of pressure riveting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

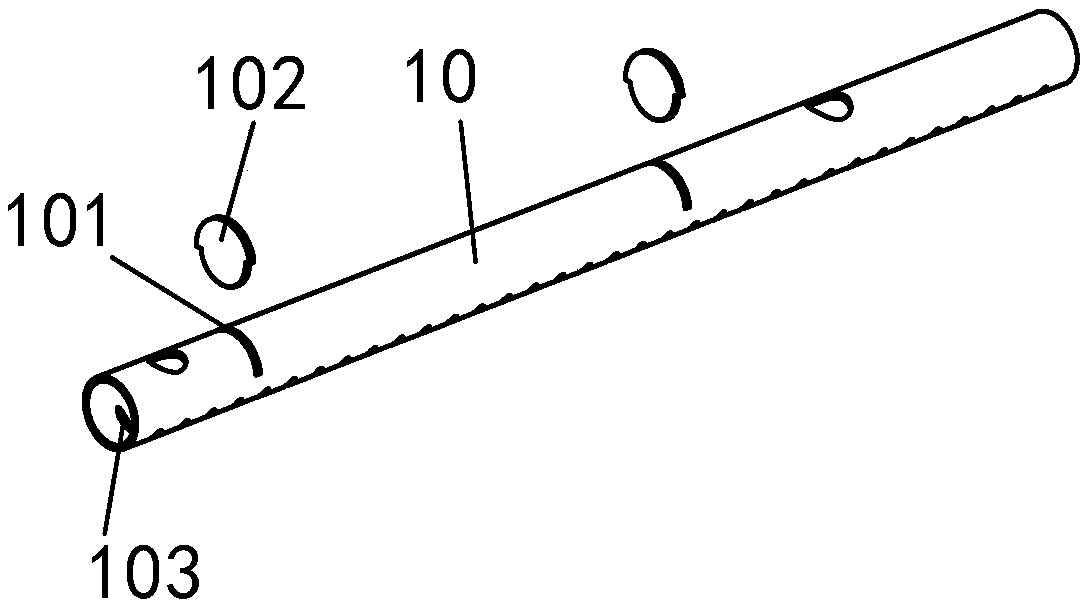

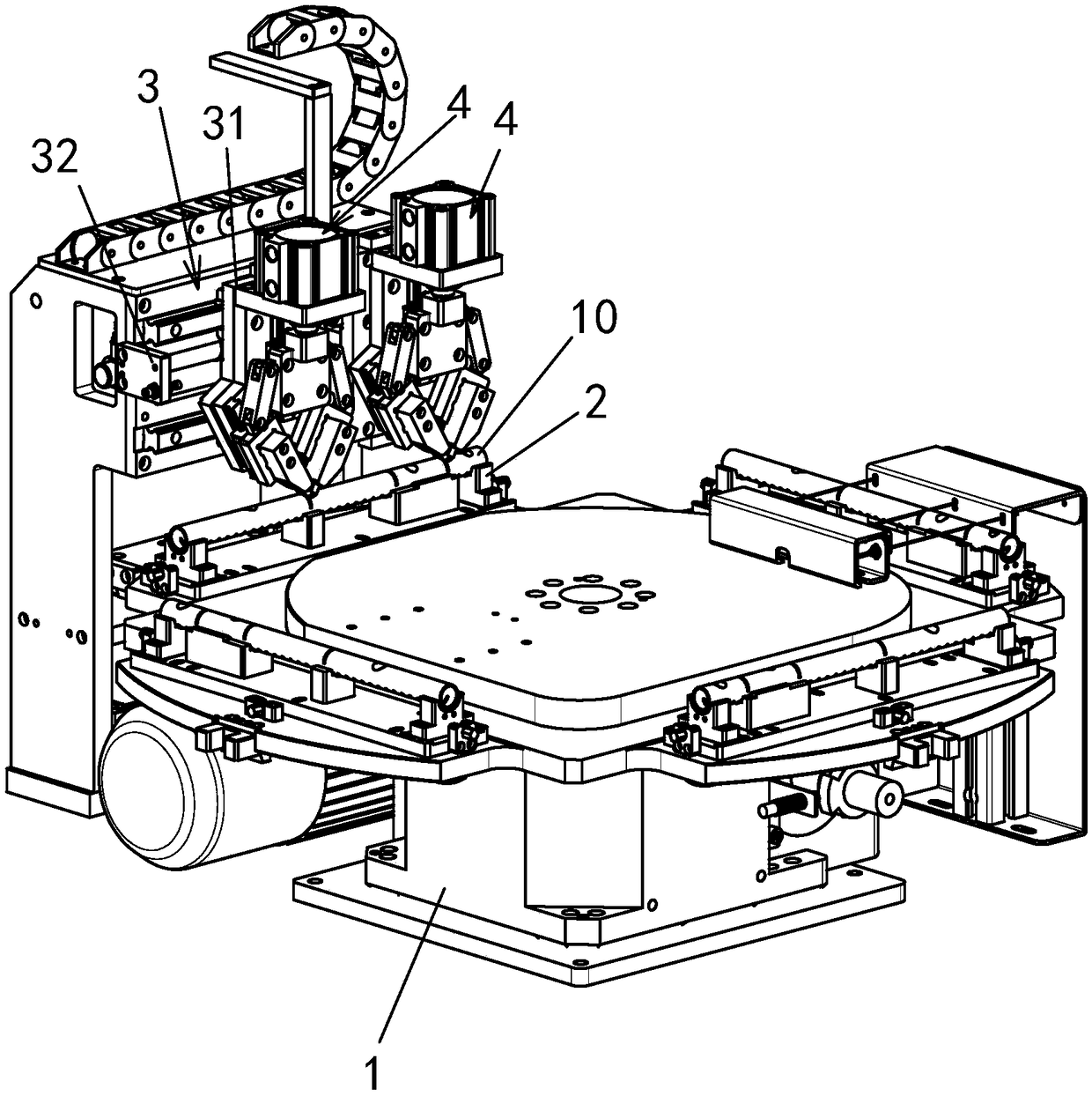

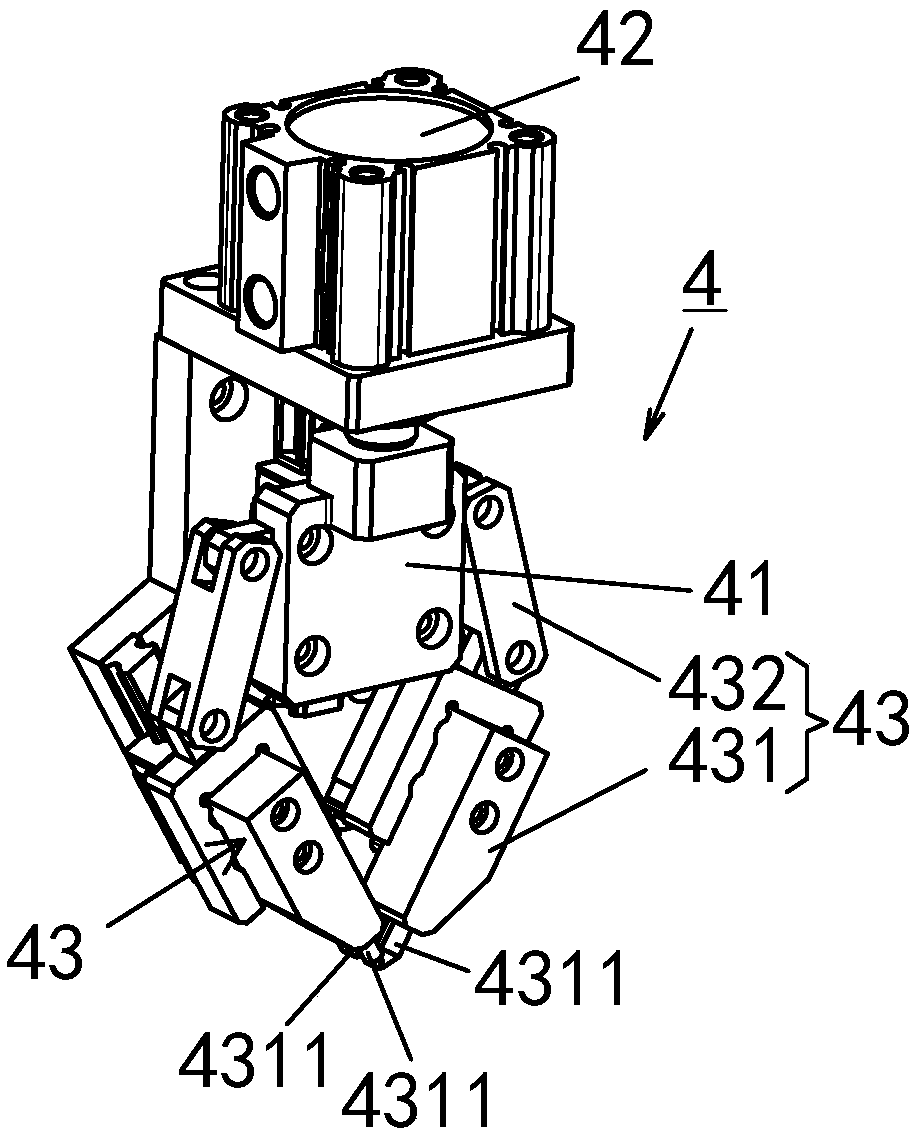

[0020] Example: see Figure 2-6 Shown:

[0021] A spacer riveting device for pipe fittings, comprising a fixed base 1, a pipe fitting positioning tool 2, a translation device 3 and a riveting unit 4 arranged on the translation device 3.

[0022] see figure 2 As shown, the pipe fitting positioning tool 2 is arranged on the fixed base 1, specifically, a turntable 11 is arranged on the fixed seat 1, and a plurality of stations are arranged on the circumference of the turntable 11, and the pipe fitting positioning tool 2 is fixed on the turntable 11 , with the rotation of the turntable to switch between multiple stations. A plurality of pipe fitting positioning tools in the circumferential direction of the turntable 11 are sequentially switched to the septum riveting station with the rotation of the turntable, and the pipe fitting septum riveting device of this embodiment is installed on the septum riveting station.

[0023] see Figure 5 , Figure 6 As shown, the pipe fitti...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap