Assembling device for stator iron core and stator coil

A technology of stator coils and stator cores, applied in electromechanical devices, metal processing, manufacturing motor generators, etc., can solve problems such as potential safety hazards, low assembly efficiency, and inconvenient placement of stator cores, and achieve safe and reliable devices and high assembly efficiency Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

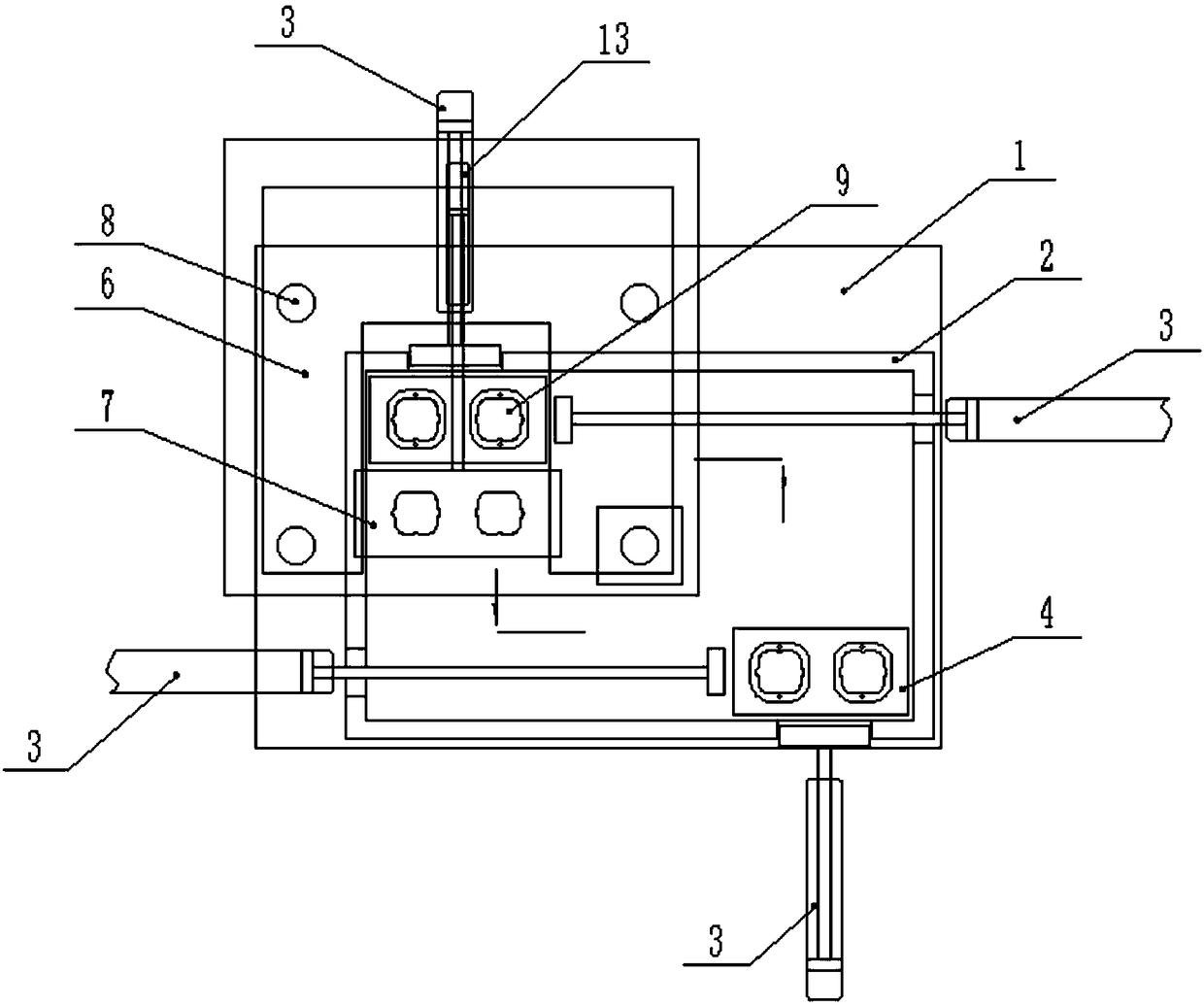

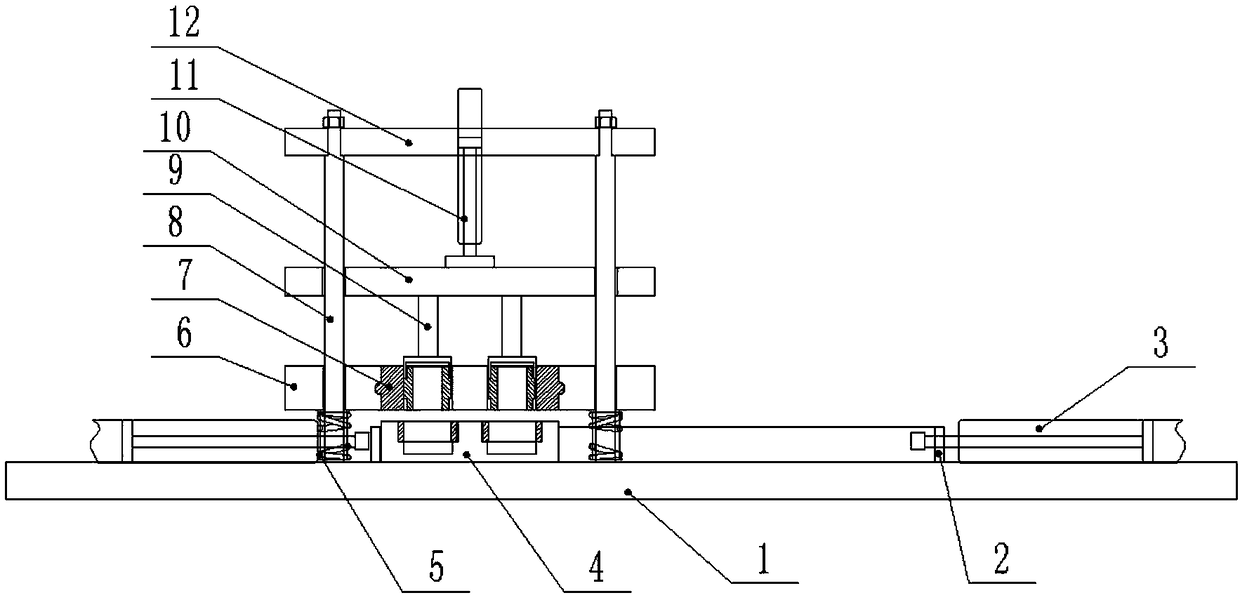

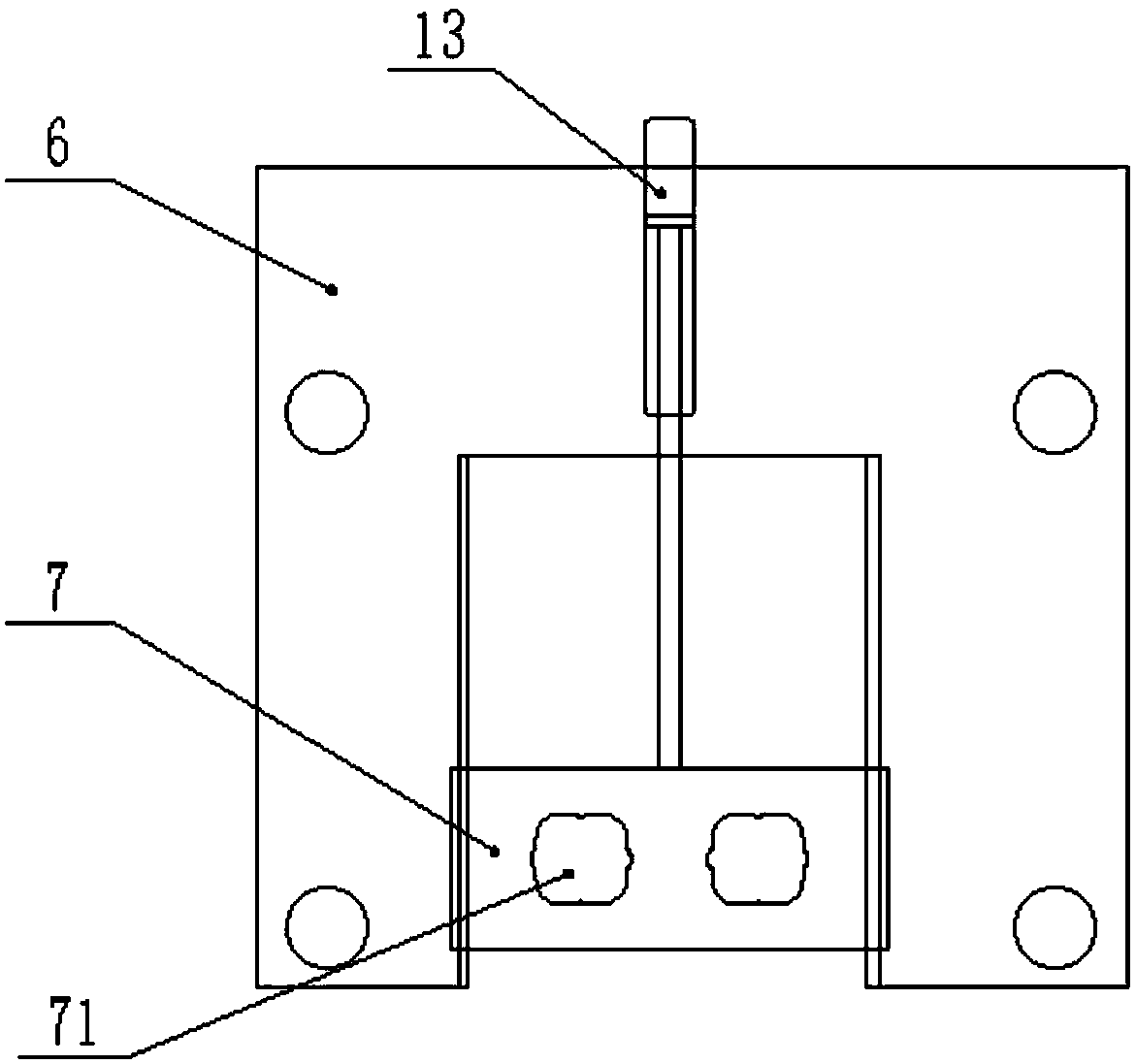

[0030] Such as figure 1 , figure 2 As shown, the assembly device of a stator core and a stator coil described in the embodiment of the present invention includes a workbench 1 on which a rectangular enclosure 2 is fixed, and a pushing cylinder 3 is fixed on the edge of the enclosure 2 At the four end corners; the guide column 8 is fixed on the workbench 1, a total of four guide columns 8 form a rectangle, one of the guide columns 8 is located in the middle of the rectangle surrounded by the hoarding plate 2, and the top of the guide column 8 is a variable diameter section, the upper platform 12 is locked on the variable diameter section by nuts, and a stamping cylinder 11 is installed in the middle of the upper platform 12; the middle platform 10 is located below the upper platform 12 and is guided by the guide column 8, and the upper surface of the middle platform 10 is connected with the stamping cylinder The cylinder shaft of 11 is fixedly connected, and the lower surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com