Method and tool for installing and disassembling roller

A technology for loading and unloading tools and rollers, which is applied to manufacturing tools, hand-held tools, etc., can solve the problems of high damage rate, uneven force and damage of expansion sleeves in rollers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

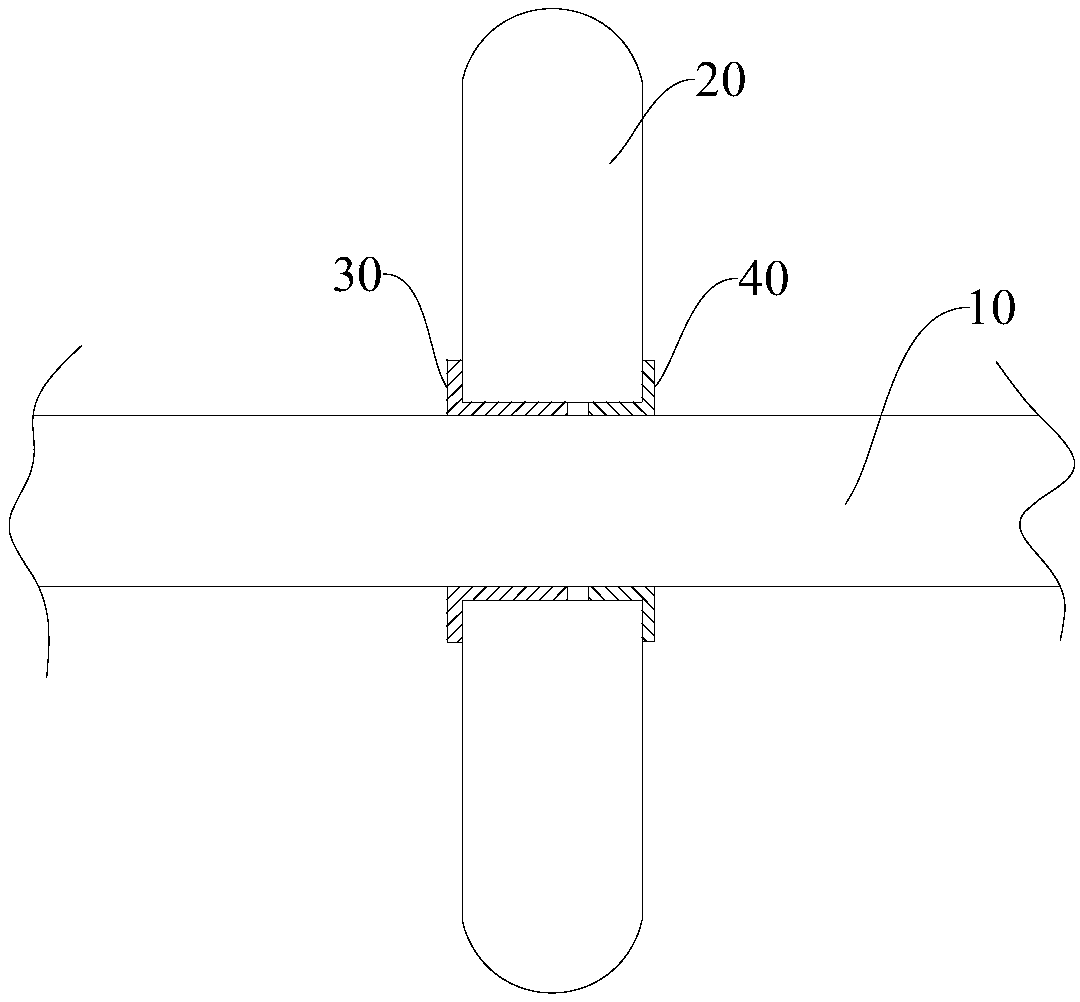

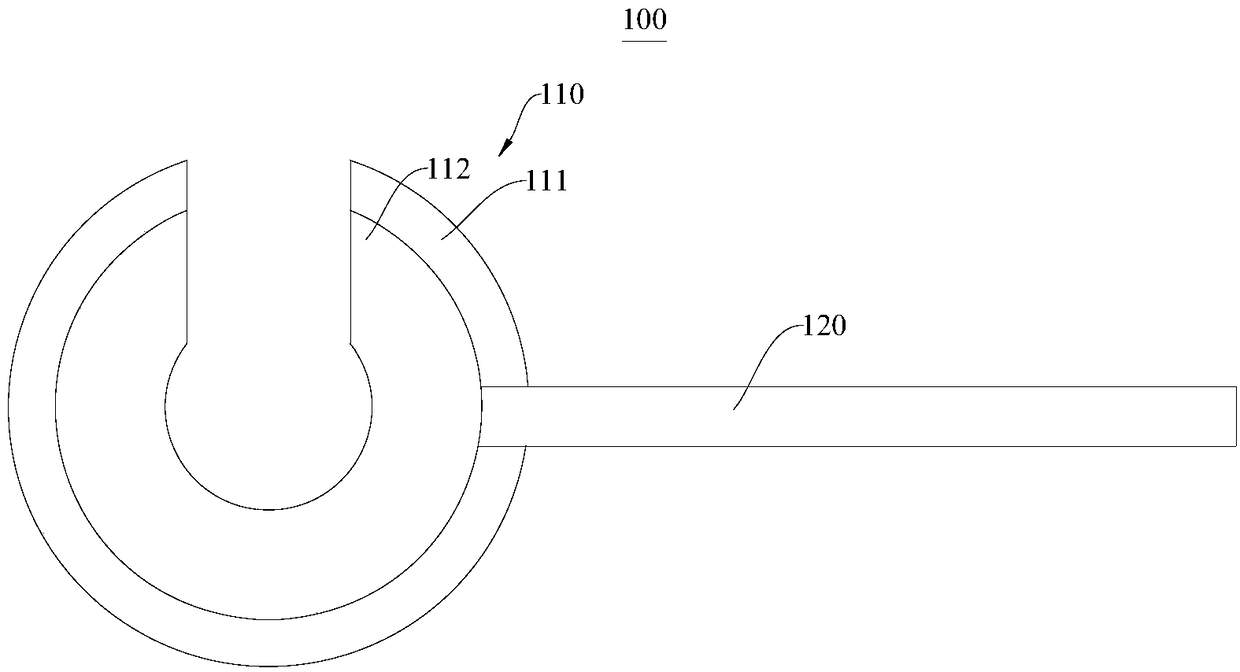

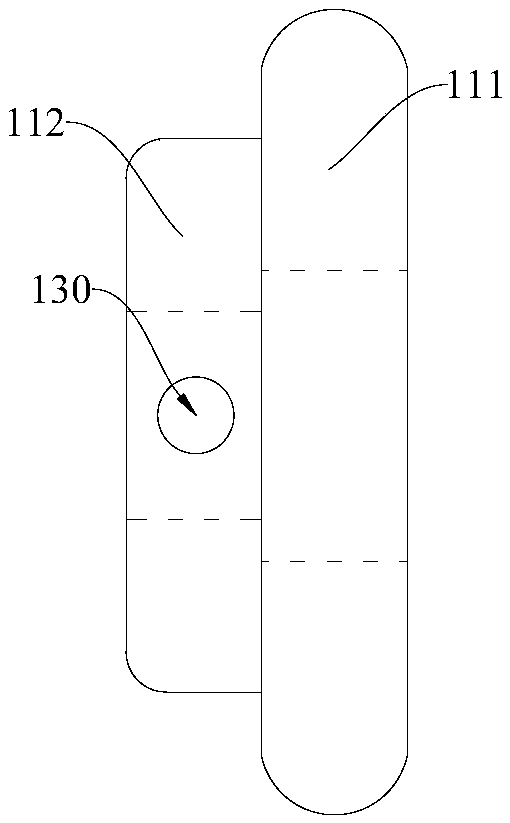

[0035] In the production of glass sheets, conveyor rollers are often used to transport the glass sheets. The rollers are usually fastened to the shaft body with an inner expansion sleeve. In order to facilitate the description of the roller handling tool according to the embodiment of the present invention, the installation structure of the roller is first introduced. figure 1 It is a schematic diagram of the installation structure of the roller in an embodiment of the present invention. Please refer to figure 1 , the inner expansion sleeve includes a male sleeve 30 and a female sleeve 40, both of which are sleeved on the shaft body 10, and the ends of the two are provided with radially outwardly extending flanges at the ends far away from each other in the axial direction, and the flanges are used to limit bit. The setting of the flange is also convenient for the male sleeve 30 or the female sleeve 40 to find a better force point during installation. The rollers 20 are sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com