Clamp for loading and unloading piercer plug

A punching machine and jig technology, applied in the field of punching machines, can solve the problems of single processing effect, poor stability, and poor adaptability, and achieve the effects of convenient and simple replacement, improved stability, and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

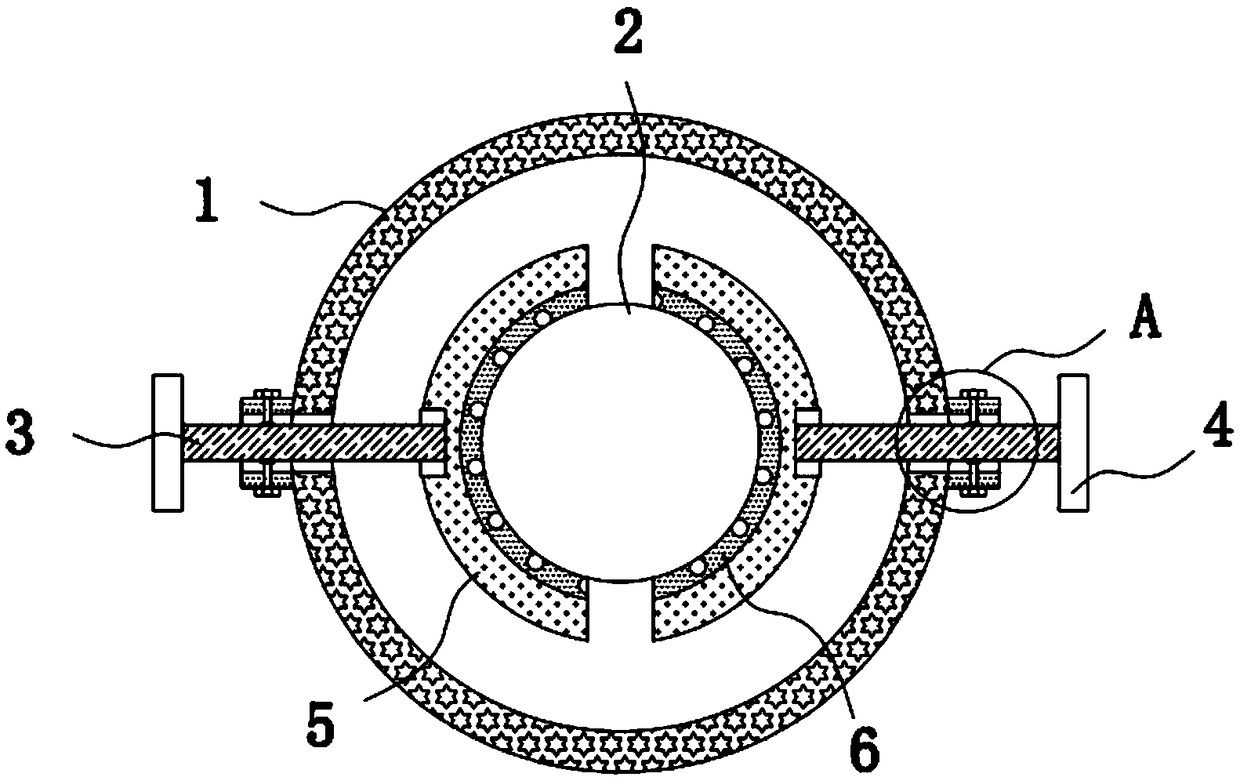

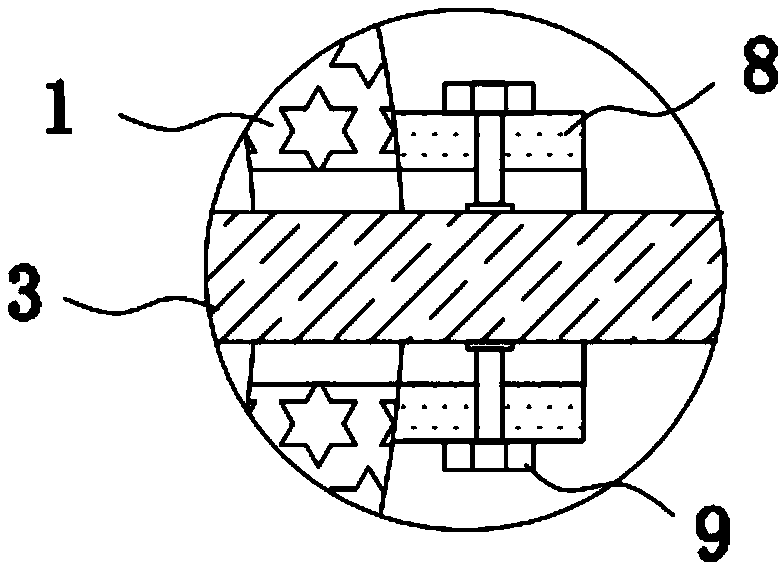

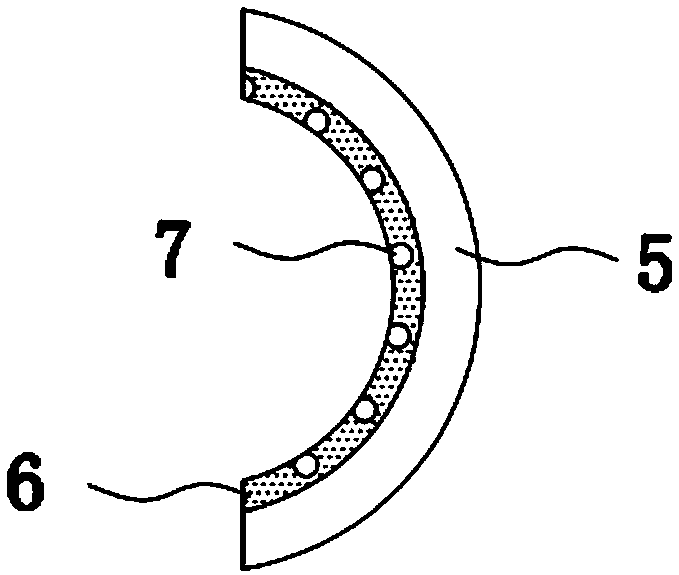

[0025] refer to Figure 1-3 It can be known that a jig for loading and unloading the head of a piercing machine in the present invention includes a fixing ring 1. The inside of the fixing ring 1 is sleeved with a plug body 2 protruding from its lower part. The left and right sides of the fixing ring 1 are screwed with screw rods. 3. The outer end of the screw rod 3 is integrally connected with a rotating hand wheel 4, and the inner end of the screw rod 3 is connected to an arc-shaped splint 5 through bearing rotation, and the inner wall of the arc-shaped splint 5 is evenly glued An anti-slip rubber pad 6 is attached to the outer wall of the plug body 2, and two anti-slip rubber pads 6 are equidistantly provided with U-shaped avoidance grooves 7 on opposite sides. The left and right sides of the outer wall of the fixing ring 1 are also integral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com