Wooden structure anti-seismic wall

A wood structure and wall technology, which is applied in the direction of walls, anti-seismic, building components, etc., can solve the problems that cannot be spliced and installed, and the lateral performance cannot meet the lateral requirements of severe earthquakes, etc., to suppress pull-out and misalignment, and improve seismic resistance Effects of Strength and Stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

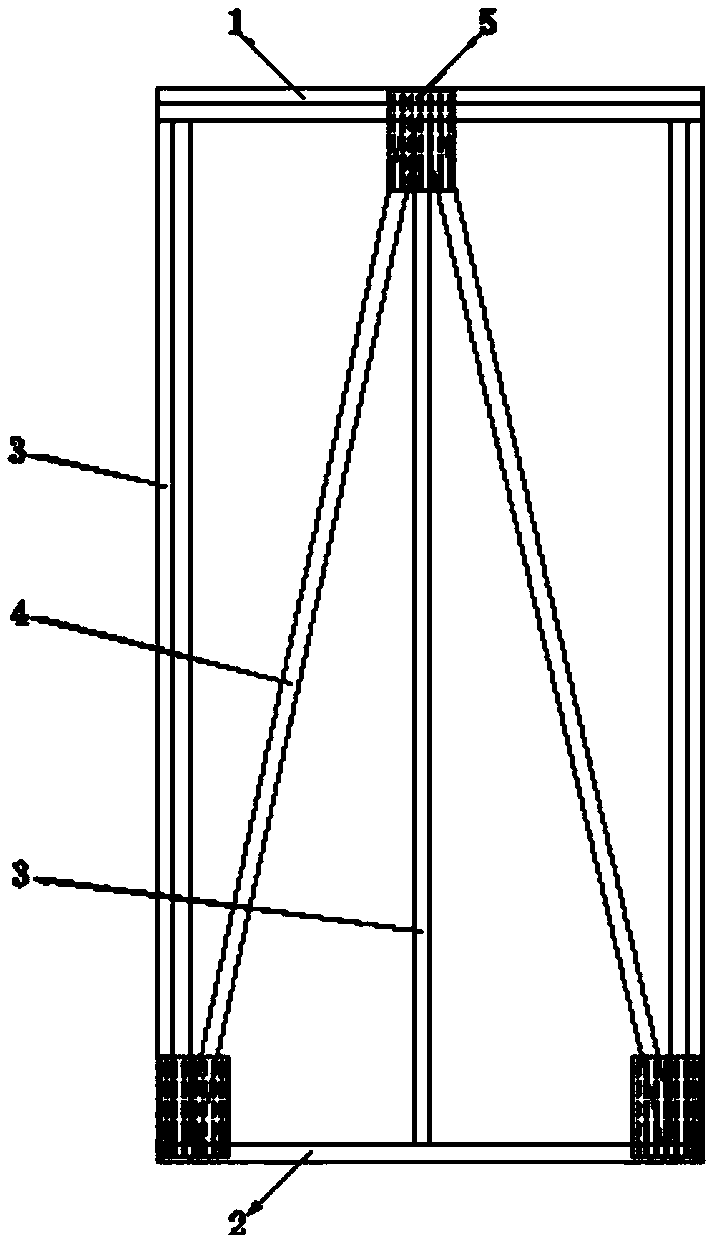

[0020] An anti-seismic wall of a wooden structure, comprising a top beam 1, a bottom beam 2, three stud columns 3, a brace 4 and a tooth plate 5; the top beam 1 and the bottom beam 2 pass through three studs The columns 3 are connected, the top ends of the three wall stud columns 3 are respectively connected to the two ends and the midpoint of the top beam plate 1, and the bottom ends are connected vertically downward to the two ends and the midpoint of the bottom beam plate 2. The connection points between the top beam plate 1, the bottom beam plate 2 and the three stud columns 3 are all vertically fixed with threaded nails. The stud 3 connecting the two ends of the top beam 1 and the bottom beam 2 is hereinafter referred to as an end stud, and the stud 3 connecting the midpoint of the top beam 1 and the bottom beam 2 is hereinafter referred to as an intermediate stud.

[0021] There are two diagonal braces 4, one end of the two diagonal braces 4 is connected and fixed to the...

Embodiment 2

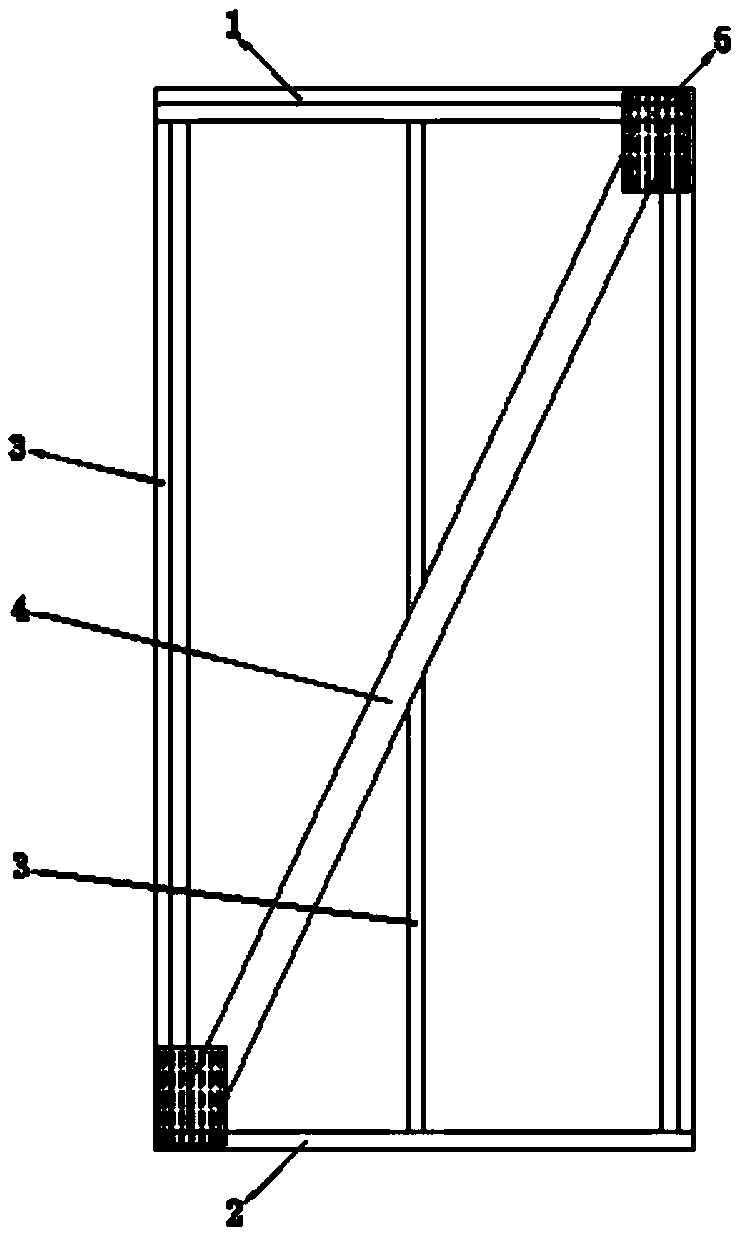

[0023] This embodiment only describes the differences from Embodiment 1, and the similarities will not be described again;

[0024] The diagonal brace 4 has one, and the diagonal brace 4 is connected in a diagonal direction, one end is connected with the bottom beam plate 2 and the bottom end of the end wall stud column, and one end is connected with the top beam plate 1 and the top end of the other end wall stud column Connection, the middle of the diagonal brace 4 is tenon-jointed with the middle wall stud column.

Embodiment 3

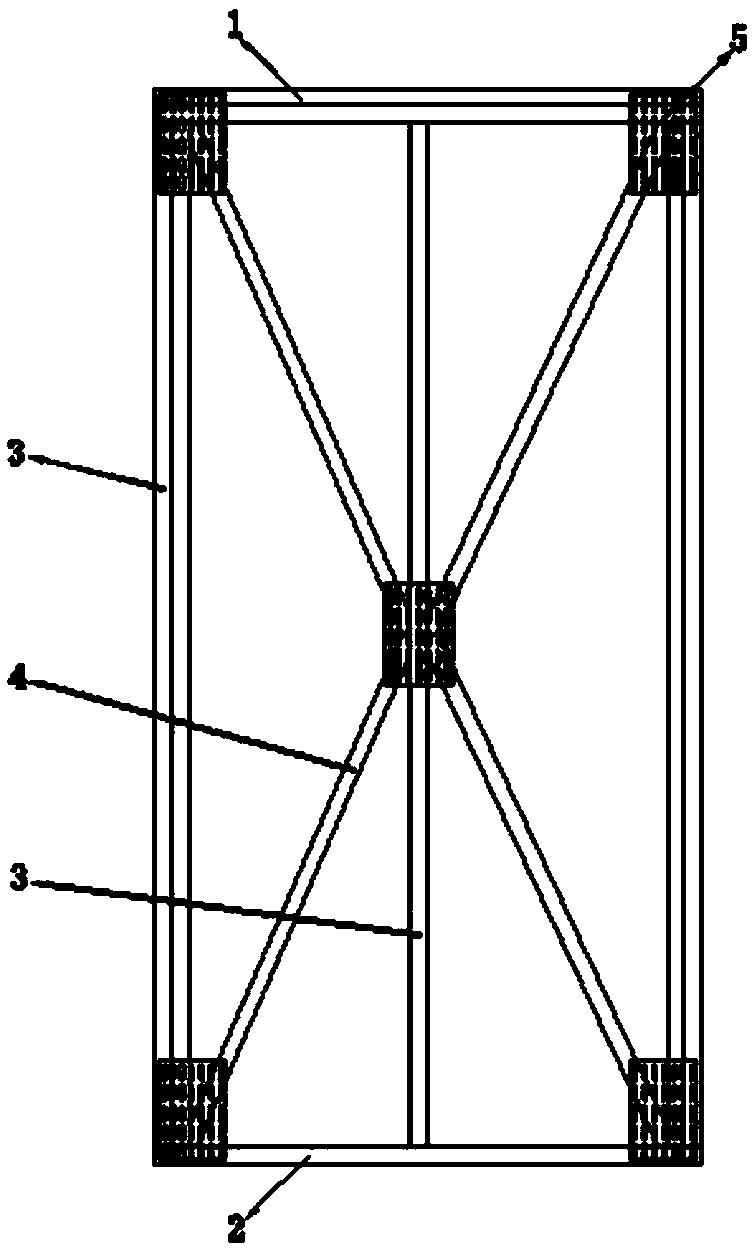

[0026] This embodiment only describes the differences from Embodiments 1 and 2, and the similarities are not described again;

[0027] There are four diagonal braces 4, one end of the four diagonal braces 4 is respectively connected to the ends of the top beam 1 and the bottom beam 2, and the other ends of the four diagonal braces 4 are flat-mouthed to the middle of the middle wall stud column . And a tooth plate 5 is provided at the connection point of four diagonal braces 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com