Reinforcing structure of square steel column

A technology for strengthening structures and square steel, applied in the direction of columns, pier columns, pillars, etc., can solve problems such as buckling damage, weak local stability, and structural collapse, so as to improve stability, eliminate buckling damage areas, and improve wind and earthquake resistance effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

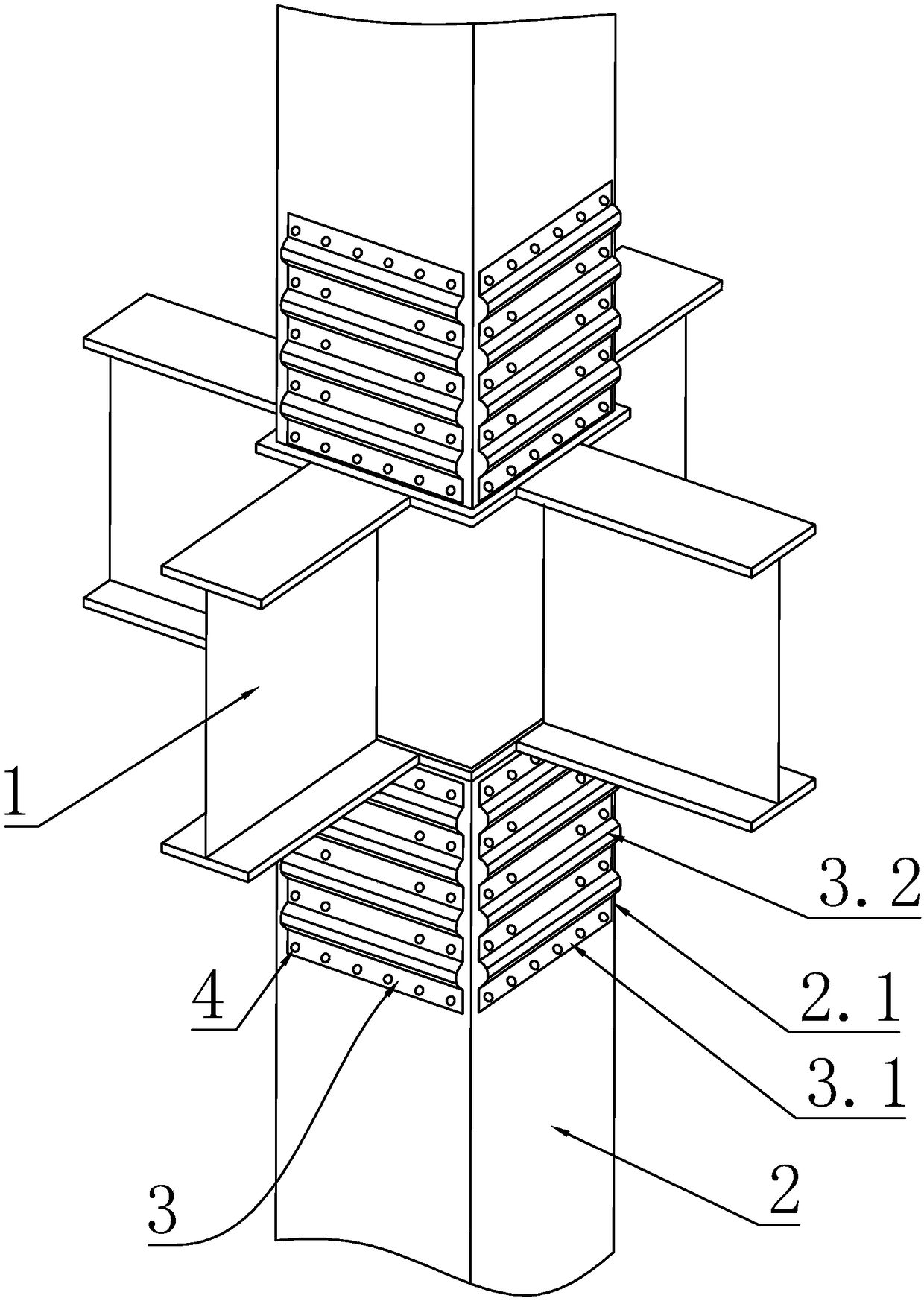

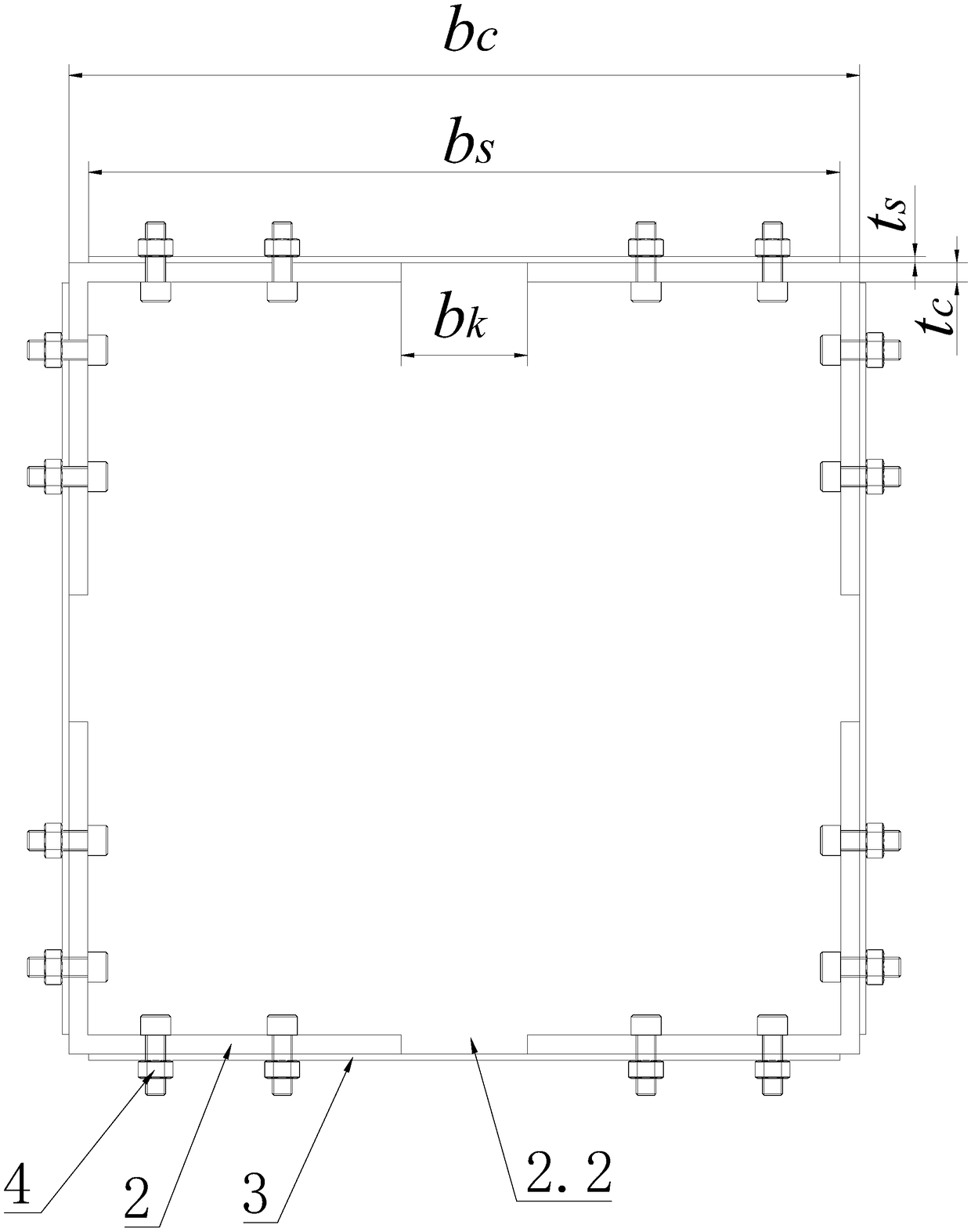

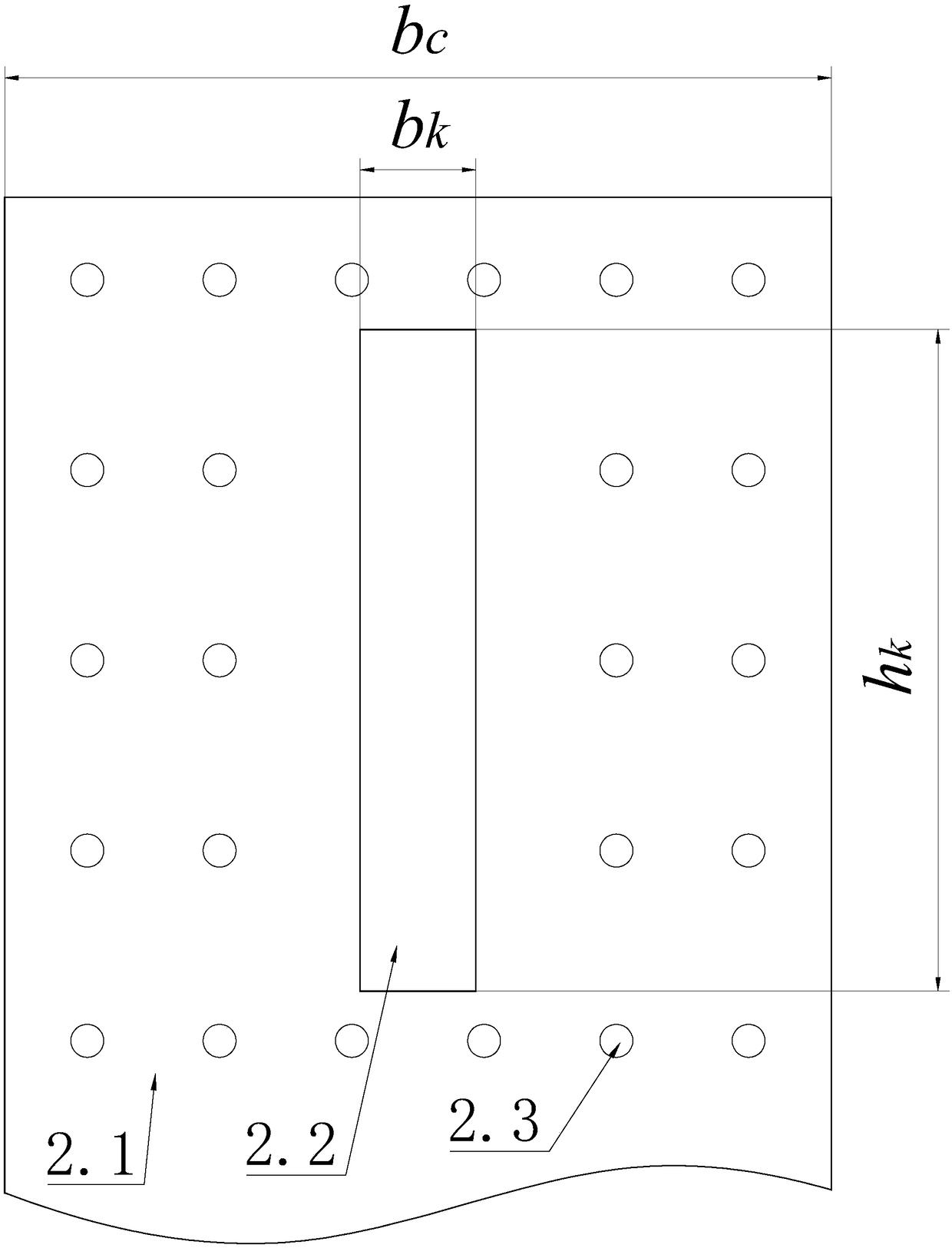

[0018] like Figure 1-3 as shown,

[0019] A reinforced structure of a square steel column, comprising a horizontally arranged beam-column connecting portion 1, and a vertically arranged square steel column 2, the square steel column 2 abuts against the beam-column connecting portion 1 through the column end 2.1 to bear the beam-column overall weight, the column end 2.1 is provided with an opening 2.2 for reducing the bending and shear bearing capacity of the column end 2.1, and the reinforcement structure also includes a reinforcing plate 3 for covering the opening 2.2, so The reinforcing plate 3 is connected to the column end 2.1 through bolts 4, and the reinforcing plate 3 includes a body 3.1 that is closely attached to the square steel column 2, and a plurality of ribs 3.2 that protrude from the body 3.1 and are arranged laterally.

[0020] Wherein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com