Device for simulating fast deflation of tire burst in automobile

A deflation device and tire blowout technology, which is applied in the direction of automobile tire testing, etc., can solve problems such as complex structural design, and achieve the effect of convenient operation, stable performance and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

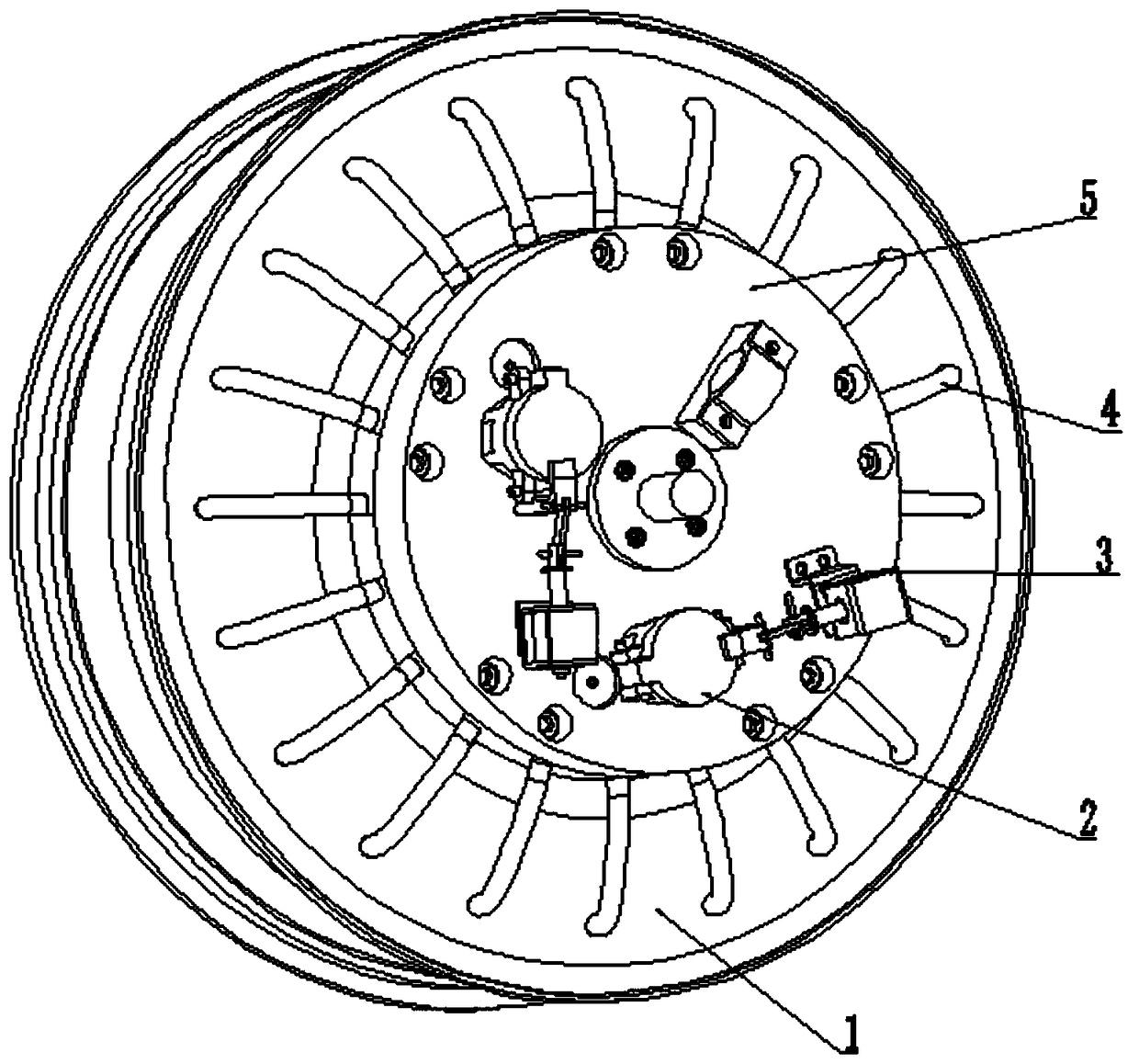

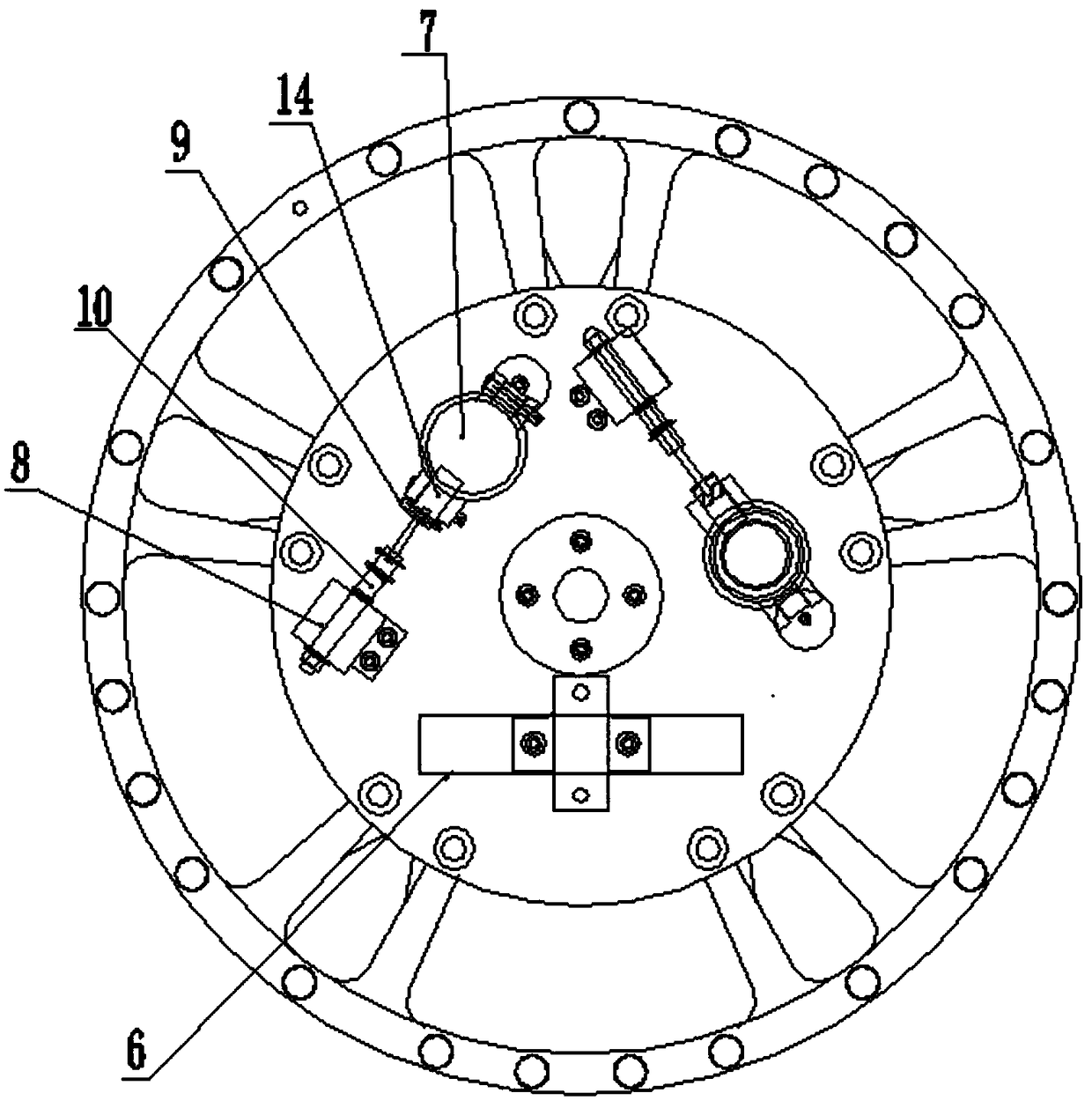

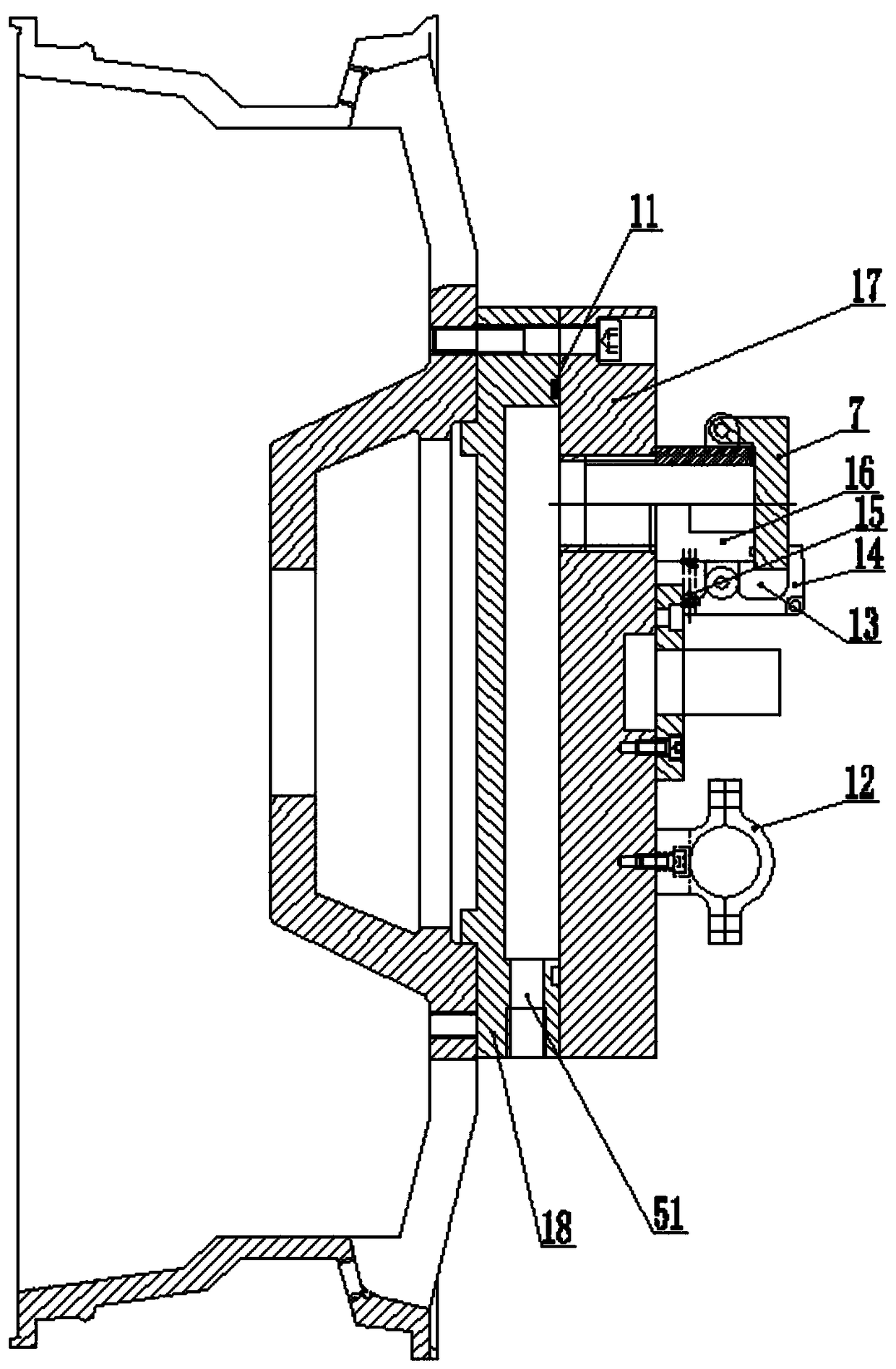

[0027] as attached Figure 1-3 As shown, a rapid deflation device for simulating a tire blowout includes a wheel rim 1, a flange sealing device 5, a pressure relief valve device 2 and a plurality of air guide pipes 4; the outer edge of the wheel rim 1 is provided with multiple Each air release hole is connected with an air hole 51 of the flange sealing device 5 through an air guide pipe 4; a sealed space is formed between the wheel rim 1, the air guide pipe 4 and the flange sealing device 5; The pressure valve device 2 is fixedly connected to the flange sealing device 5, and the pressure relief valve device 2 is opened to discharge the gas in the tire from a plurality of air guide pipes, simulating a car tire blowout.

[0028] like image 3 As shown, the flange sealing device 5 includes a flange upper part 17 and a flange lower part 18, and the flange upper part 17 and the flange lower part 18 are sealed and connected, and a cavity is formed in the middle as a flange cavity; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com