Metope percussion sound wave detecting device

A technology of a sound wave detection device and a tapping rod, which is applied in the measurement device, the analysis of solids using sonic/ultrasonic/infrasonic waves, and the material analysis using sonic/ultrasonic/infrasonic waves, etc. Detect reliable and accurate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

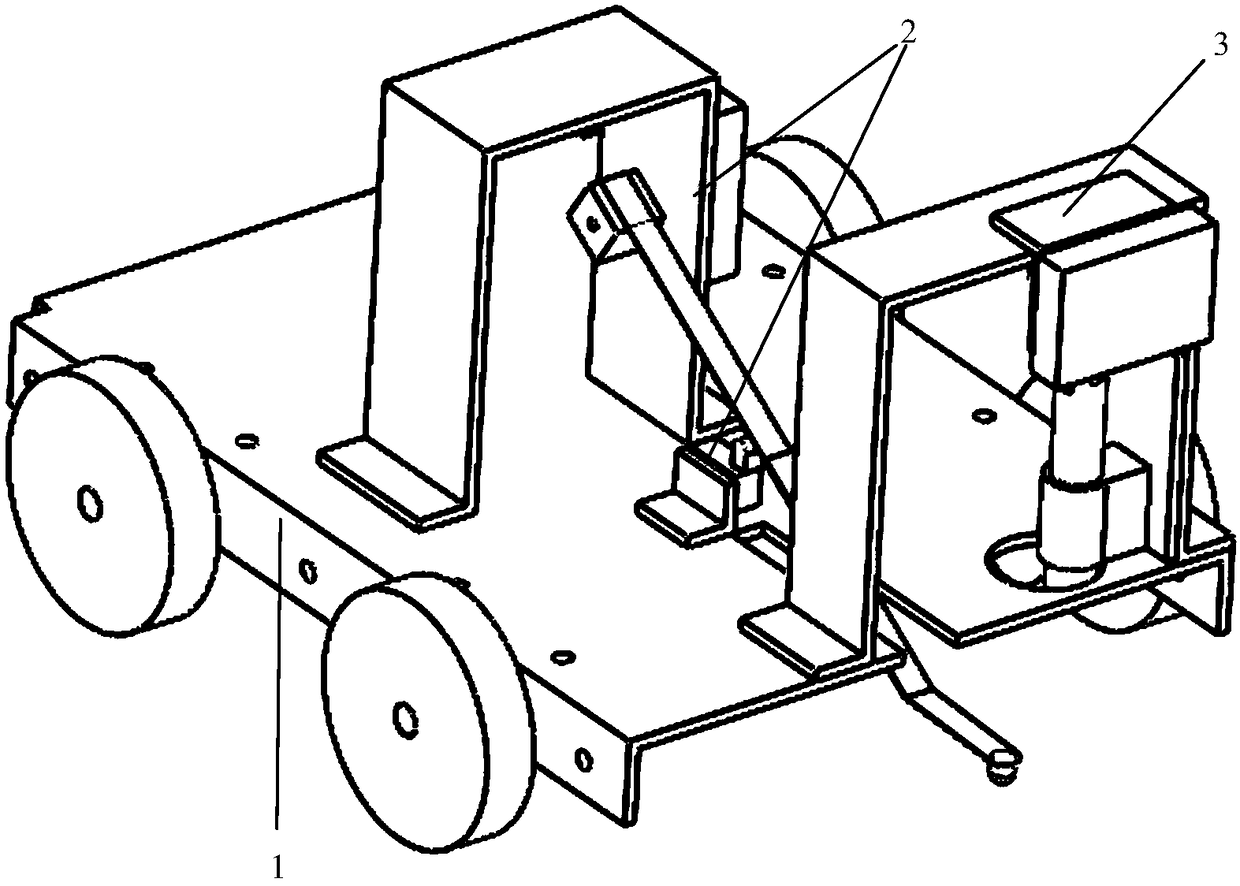

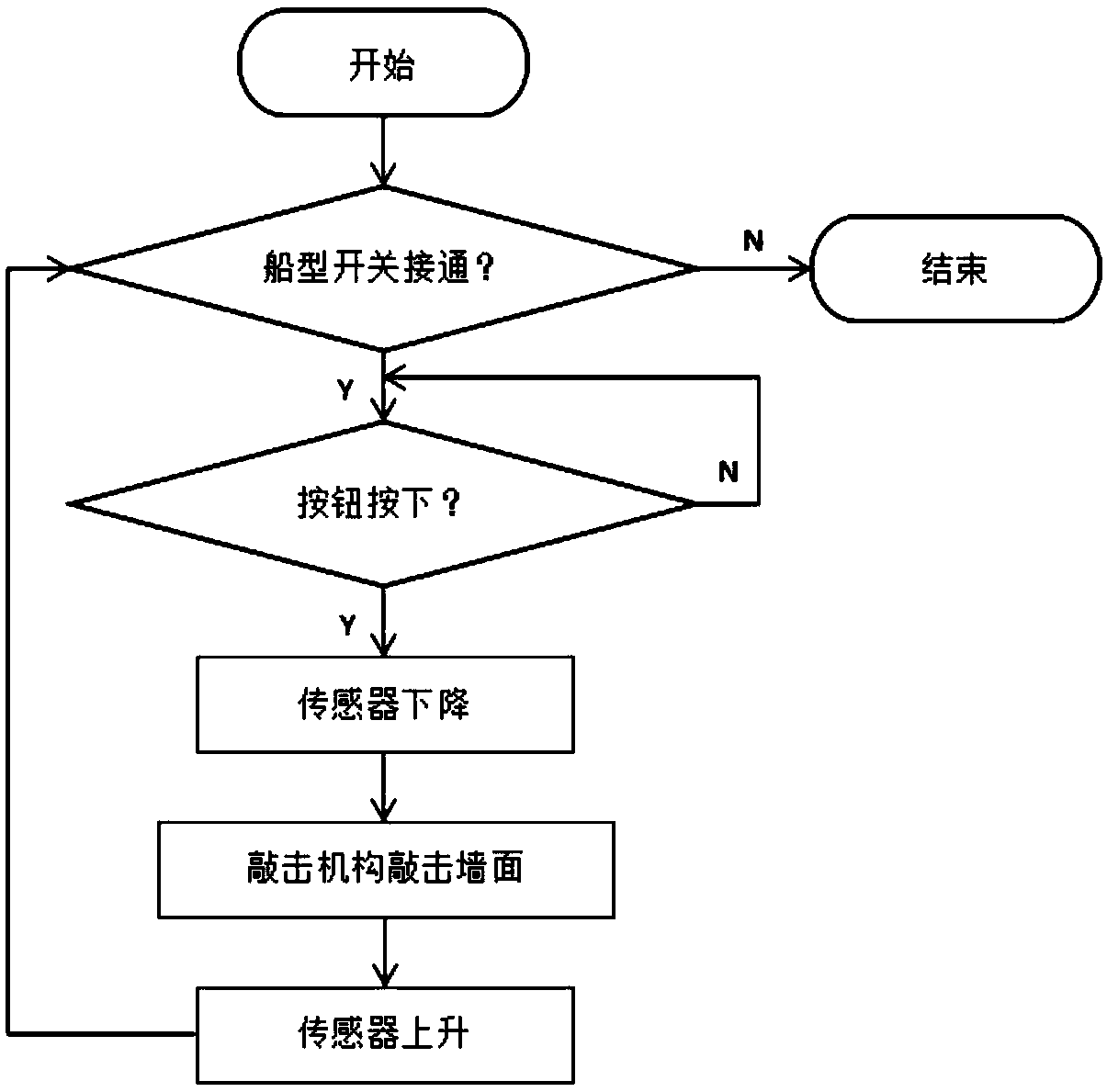

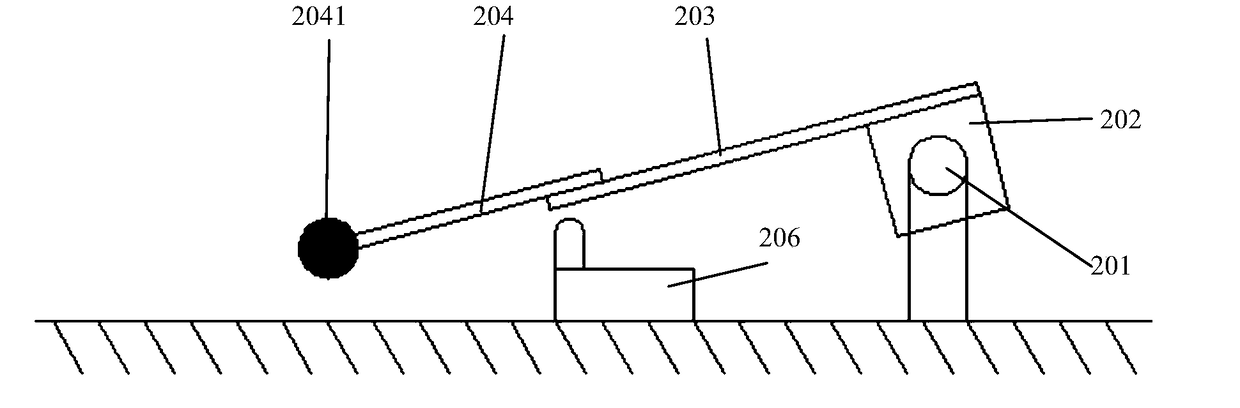

[0048] A sound wave detection device for wall percussion, such as figure 1 As shown, it includes a vehicle body 1, a percussion unit 2, a sensor unit 3, and a controller (not shown), wherein: the vehicle body 1 is used to move on the wall; the percussion unit is arranged on the vehicle body 1, including a drive connected in turn Drive assembly, elastic action assembly and percussion block. The drive assembly acts on the elastic action assembly by rotating and drives the action of the elastic action assembly, so that the percussion block strikes the wall once and bounces within a working cycle; sensor unit 3 It is set on the body 1 and includes a sound wave sensor and a sensor lifting assembly. The sensor lifting assembly drives the sound wave sensor down to fit the wall before the knocking block hits the wall, and drives the sound wave sensor to reset after the knock is completed; To control the actions of the percussion unit and the sensor unit.

[0049] In this embodiment, such...

Embodiment 2

[0059] Such as Picture 10 with Picture 12 As shown, the wall tap sound wave detection device of this embodiment includes a vehicle body 1, a tap unit 4, a sensor unit 3, and an electronic control module.

[0060] The vehicle body 1, the percussion unit 4, the sensor unit 3 and the electronic control module of this embodiment are basically the same as those of the first embodiment. the difference lies in:

[0061] In this embodiment, the drive assembly includes a shift lever right angle motor 4032 and a dial shift lever mechanism. The dial shift lever mechanism consists of a dial A4035 connected to the shaft of the shift lever right angle motor 4032 and a multiplicity evenly distributed along the circumference of the dial A4035. Consists of two shift rods 4038 (in this embodiment, there are four shift rods 4038, and the corresponding center angles of two adjacent shift rods 4038 are 90°)

[0062] In this embodiment, the knock block is a knock block B4016.

[0063] In this embodiment...

Embodiment 3

[0071] Such as Figure 16 As shown, the wall knock sound wave detection device of this embodiment includes a vehicle body 1, a knock unit 5, a sensor unit 3, and an electronic control module.

[0072] The body 1, the percussion unit 5, the sensor unit 3, and the electronic control module of this embodiment are basically the same as those of the first embodiment. the difference lies in:

[0073] In this embodiment, the drive assembly includes a shift block right-angle motor A503 and a dial shift block mechanism. The dial block mechanism consists of a dial B502 connected to the shaft of the shift block right-angle motor A503 and a plurality of dials evenly distributed along the circumference of the dial B502. It is composed of two dial blocks A501 (in this embodiment, there are four dial blocks A501, and the center angles corresponding to two adjacent dial blocks A501 are 90°).

[0074] The knock block in this embodiment is a knock block C507.

[0075] The elastic action component in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com