Large-light-out-angle Mini LED backlight module and manufacturing method thereof

A technology of backlight modules and manufacturing methods, applied in optics, nonlinear optics, instruments, etc., can solve the problems of increasing the cost of backlight modules, high chip failure rate, and reducing panel yield, so as to achieve low failure rate and improve yield rate, the effect of Mini LED chip reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

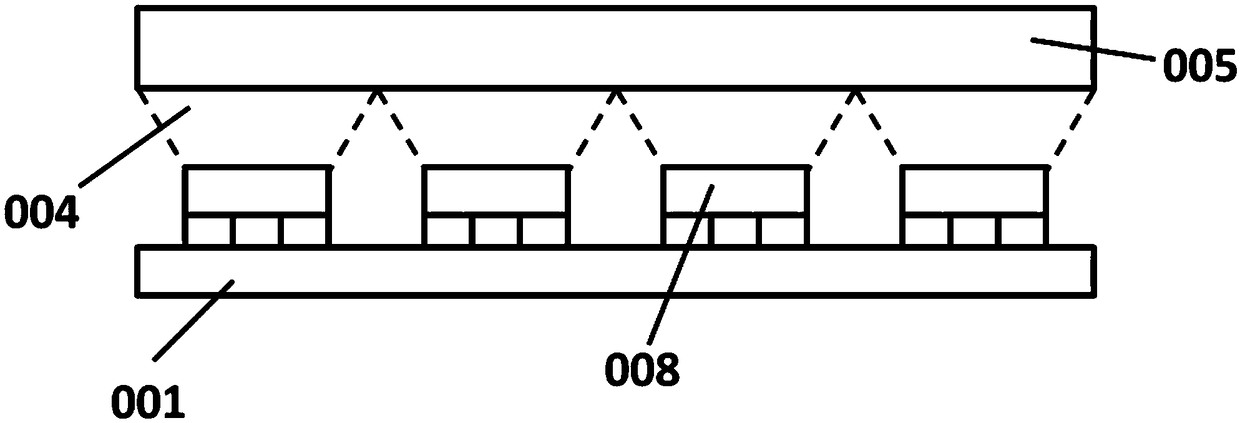

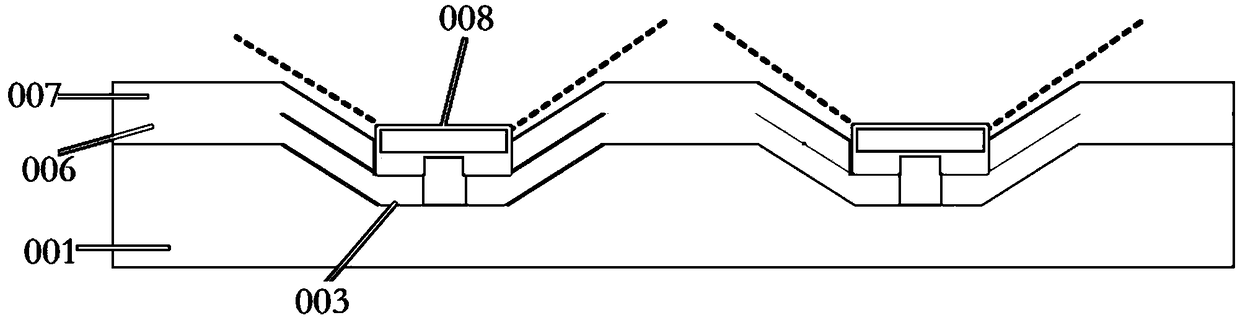

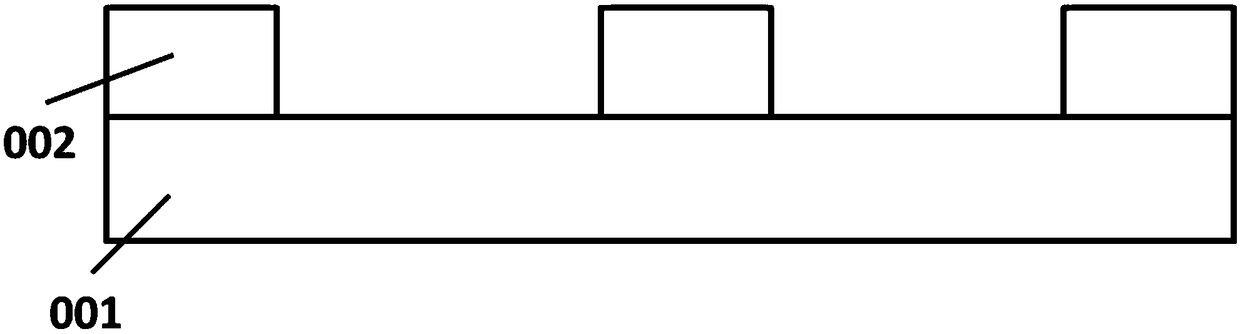

[0031] Embodiment 1: A Mini LED backlight module with a large light output angle, including a substrate 001, and an inverted trapezoidal pit 003 is arranged in the substrate 001, and a metal conductive layer 006 is deposited on the substrate 001 and covered with a metal layer. The white ink layer 007 on the conductive layer 006 is provided with a Mini LED chip 008 in the inverted trapezoidal pit 003, and the electrodes below the Mini LED chip 008 are electrically connected to the metal conductive layer 006 for leading out the electrodes of the Mini LED chip 008, And the side of the Mini LED chip 008 is in contact with the white ink layer 007;

[0032] The depth of the inverted trapezoidal pit 003 is greater than the thickness of the Mini LED chip 008, and the bottom angle of the inverted trapezoidal pit 003 is greater than 130°.

[0033] The substrate 001 in this embodiment includes a ceramic substrate, a PCB board or other insulating boards.

[0034] A method for manufacturi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com