Material screening device

A screening device and material technology, applied in the direction of screen, solid separation, grid, etc., can solve the problems of the structure, damage, complex screening device body, etc. of the vibration and vibration screening machine that cannot be fed and discharged at the same time, so as to save the use of Cost, Reinforcement Structure, Loss Reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

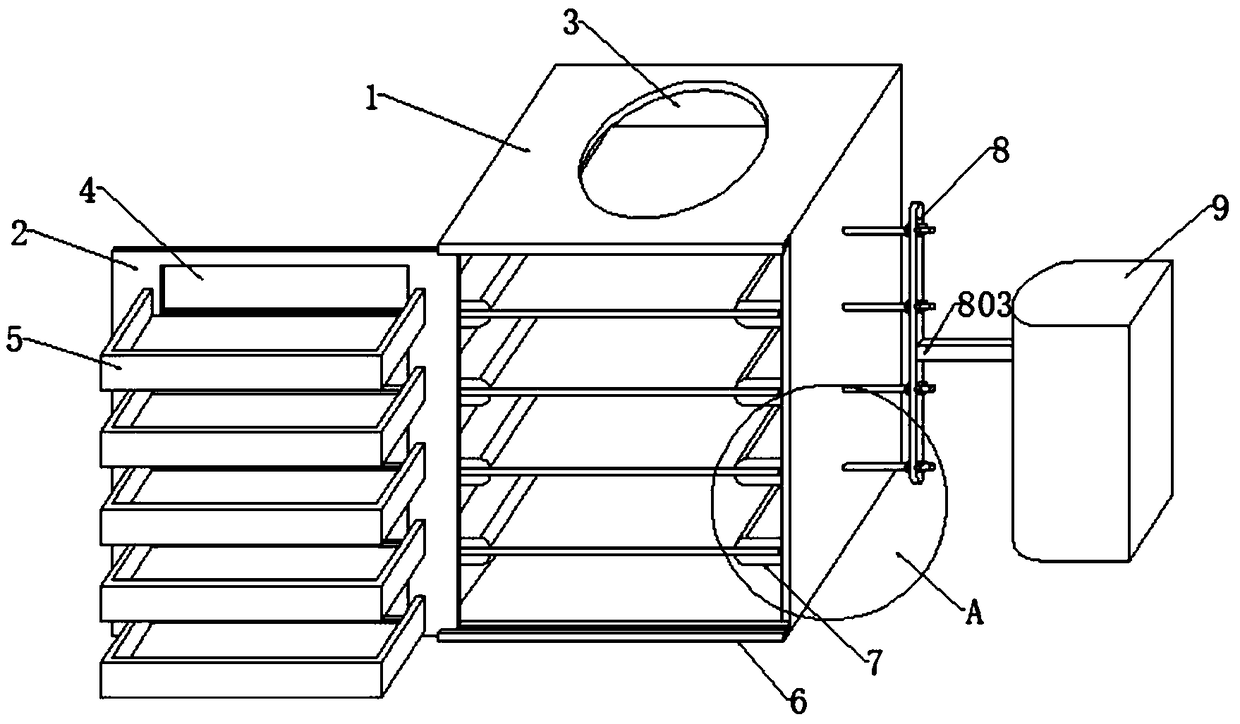

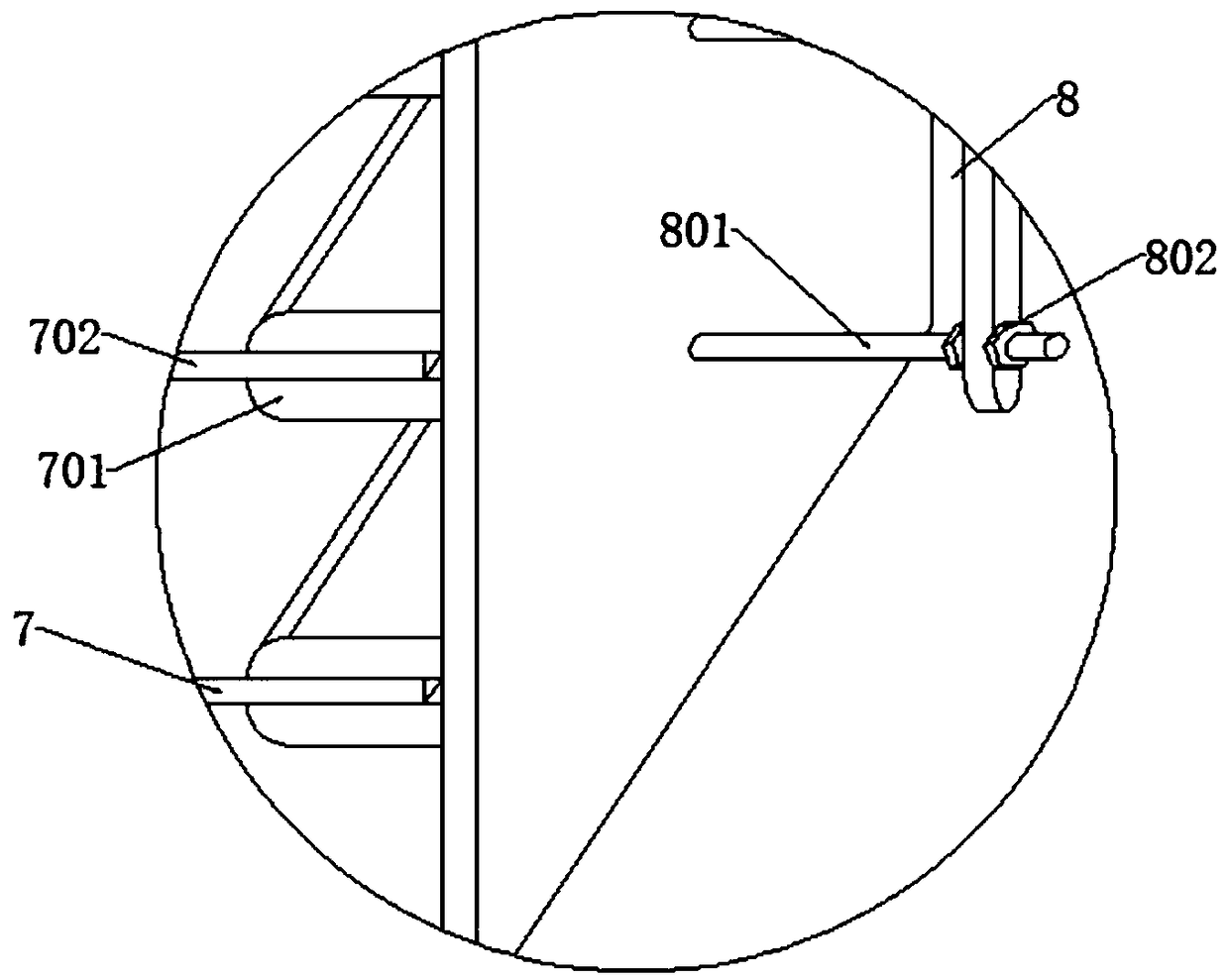

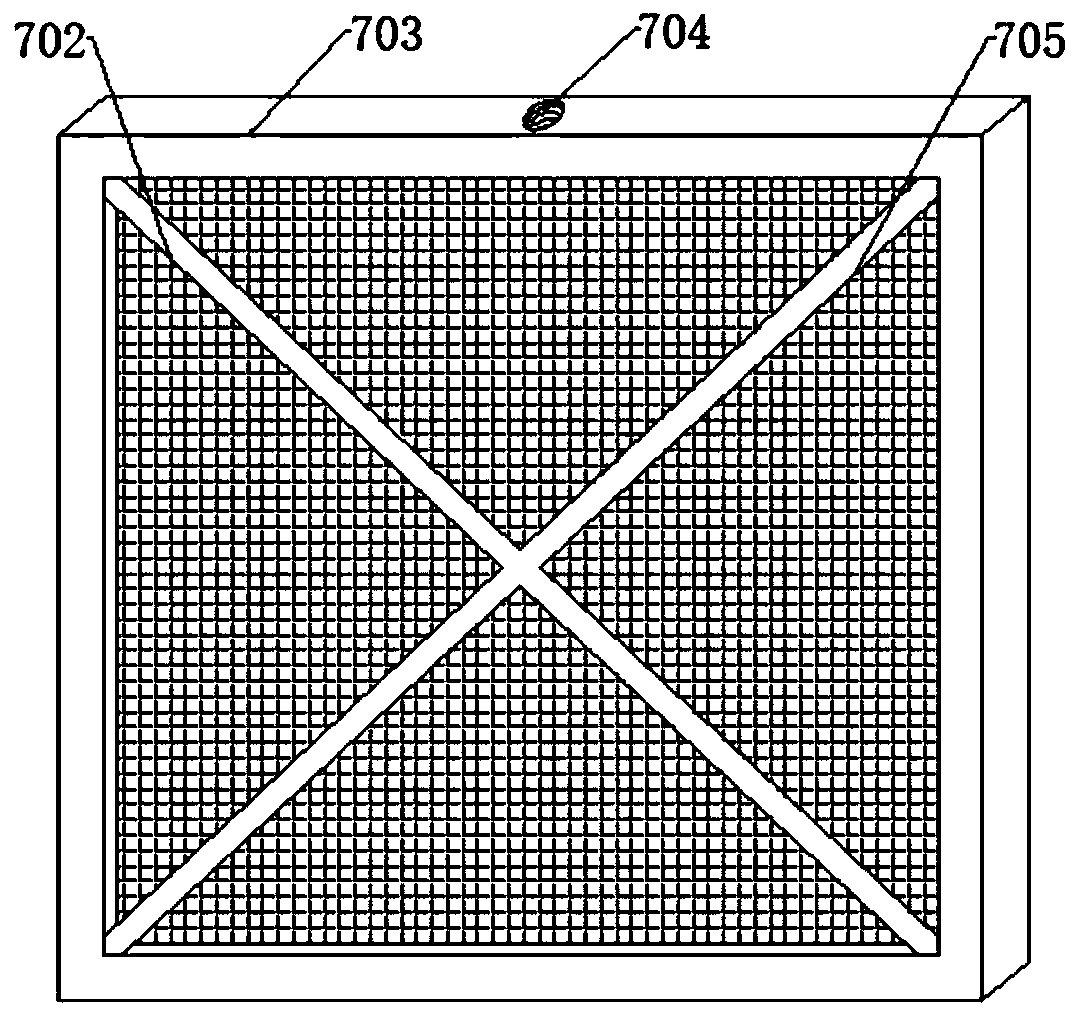

[0027] A material screening device, such as Figure 1-4 As shown, it includes a device body 1, a sliding door 2 and a sieving device 9, the top of the device body 1 has a feed port 3, the inside of the device body 1 is a hollow structure, and the inside of the device body 1 is provided with At least one screening mechanism 7, the screening mechanism 7 evenly divides the inside of the device body 1 into at least two screening bins, the screening mechanism 7 includes a clamping fixed piece 701 and a screen 702, the screen 702 The top side and the bottom side of the edge of the screen are provided with a clamping fixing piece 701, one side of the clamping fixing piece 701 is closely attached to the inside of the device body 1 and fixed, and the outside of the screen 702 is provided with a fixing frame 703, so that The bottom of the fixed frame 703 is tightly fixed with at least two cross-fixed reinforcing rods 705, and the middle part of the top of the fixed frame 703 has a screw...

Embodiment 2

[0029] A material screening device, such as Figure 1-4 As shown, it includes a device body 1, a sliding door 2 and a sieving device 9, the top of the device body 1 has a feed port 3, the inside of the device body 1 is a hollow structure, and the inside of the device body 1 is provided with At least one screening mechanism 7, the screening mechanism 7 evenly divides the interior of the device body 1 into at least two screening bins, the screening mechanism 7 includes a clamping fixed piece 701 and a screen 702, the screen 702 Both the top side and the bottom side of the edge of the screen are provided with a clamping fixing piece 701, one side of the clamping fixing piece 701 is tightly fitted and fixed to the inside of the device body 1, and the outside of the screen 702 is provided with a fixing frame 703, so that The bottom of the fixed frame 703 is tightly fixed with at least two cross-fixed reinforcing rods 705, and the middle part of the top of the fixed frame 703 has a ...

Embodiment 3

[0032] A material screening device, such as Figure 1-4As shown, it includes a device body 1, a sliding door 2 and a sieving device 9, the top of the device body 1 has a feed port 3, the inside of the device body 1 is a hollow structure, and the inside of the device body 1 is provided with At least one screening mechanism 7, the screening mechanism 7 evenly divides the inside of the device body 1 into at least two screening bins, the screening mechanism 7 includes a clamping fixed piece 701 and a screen 702, the screen 702 The top side and the bottom side of the edge of the screen are provided with a clamping fixing piece 701, one side of the clamping fixing piece 701 is closely attached to the inside of the device body 1 and fixed, and the outside of the screen 702 is provided with a fixing frame 703, so that The bottom of the fixed frame 703 is tightly fixed with at least two cross-fixed reinforcing rods 705, and the middle part of the top of the fixed frame 703 has a screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com