Diamond abrasive tool and preparation method thereof

A diamond and abrasive technology, applied in the field of abrasives, can solve the problems of short life of electroplated diamond grinding heads, uneven distribution of abrasives, easy falling off of the grinding layer, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

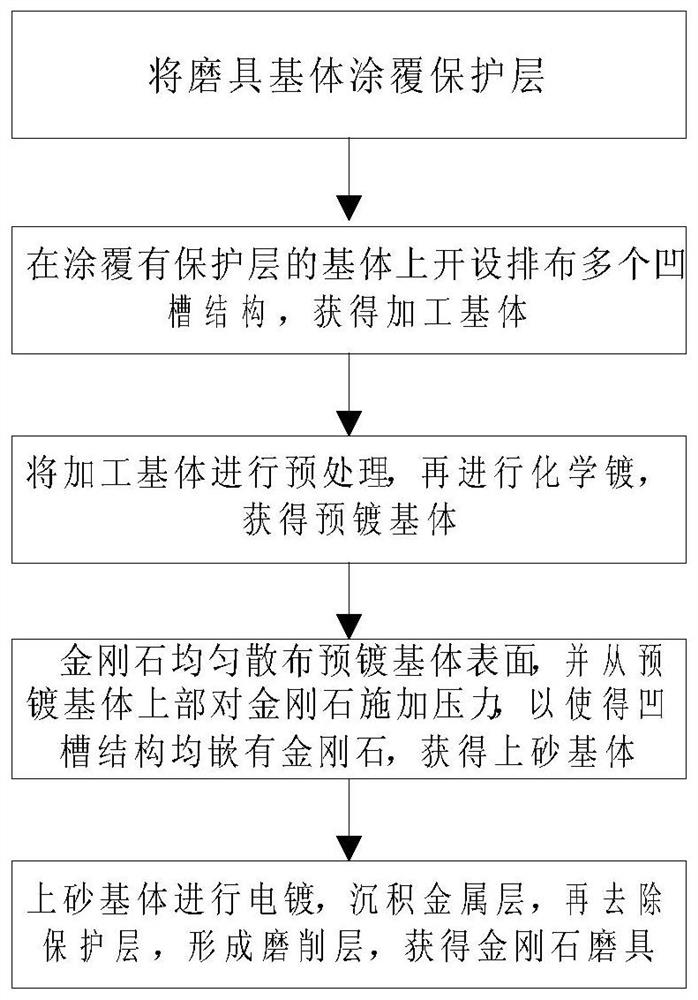

[0025] Such as figure 1 As shown, the preparation method of the diamond abrasive tool of the present embodiment includes the following steps: coating the abrasive tool substrate with a protective layer; opening and arranging a plurality of groove structures on the substrate coated with the protective layer to obtain the processed substrate; Process the substrate for pretreatment, and then perform chemical pre-plating to obtain a pre-plating substrate; diamonds are evenly spread on the surface of the pre-plating substrate, and pressure is applied to the diamond from the upper part of the pre-plating substrate, so that the groove structure is embedded with diamonds to obtain a sand-coated substrate Electroplating the upper sand base, depositing a metal layer on the diamond surface and groove structure, and then removing the protective layer to form a grinding layer to obtain a diamond abrasive tool. The preparation method of the diamond abrasive tool of the present invention com...

Embodiment 1

[0038] (1) Use a CNC lathe to turn the abrasive matrix as required.

[0039] (2) Spray the ink on the base of the abrasive tool, and then bake it in an oven at 160°C for 25 minutes. The thickness of the ink is 0.01mm.

[0040] (3) Use a laser radium engraving machine to engrave the groove structure on the abrasive tool substrate sprayed with ink. The width of the groove structure is 0.65mm, the depth is 0.16mm, and the distance between the groove structure and the groove structure is 0.9mm. The frequency is 100kHz, the emission time is 50μs, and the scanning speed is 2000mm / s to obtain the processed substrate.

[0041] (4) Pre-treat the processed substrate, including: (1) Ultrasonic treatment: Ultrasonic treatment is performed in Wuhan Aobang degreasing powder 60g / L solution at a temperature of 65°C for 10 minutes at an ultrasonic frequency of 28kHz; (2) Electrolytic degreasing: in Wuhan Aobang degreasing powder 50g / L and 15g / L sodium hydroxide solution, the temperature is 40...

Embodiment 2

[0045] (1) Use a CNC lathe to turn the abrasive matrix as required.

[0046] (2) Spray the base of the abrasive tool with baking varnish, and then bake it in an oven at 150°C for 30 minutes, and the thickness of the ink is 0.02mm.

[0047] (3) Use a laser radium engraving machine to engrave the groove structure on the abrasive tool substrate sprayed with ink. The width of the groove structure is 0.2mm, the depth is 0.04mm, and the distance between the groove structure and the groove structure is 0.3mm. The frequency is 60kHz, the emission time is 80μs, and the scanning speed is 800mm / s to obtain the processed substrate.

[0048] (4) Pre-treat the processed substrate, including: (1) Ultrasonic treatment: Ultrasonic treatment is performed in Wuhan Aobang degreasing powder 60g / L solution at a temperature of 65°C for 10 minutes at an ultrasonic frequency of 28kHz; (2) Electrolytic degreasing: in Wuhan Aobang degreasing powder 50g / L and 15g / L sodium hydroxide solution, the tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com