Pull-out component unlocking mechanism

An unlocking mechanism and pull-out technology, which is applied in the field of optical module unlocking mechanism, can solve problems such as too many components not suitable for assembly, complex structure, and difficult unlocking, and achieve the effects of easy plugging and unplugging, simple operation, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

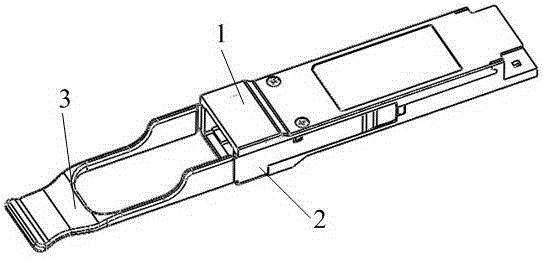

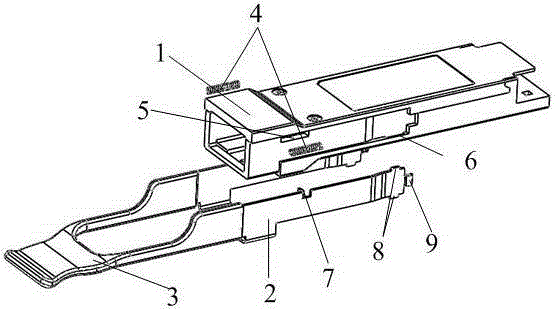

[0014] Such as figure 1 , figure 2 As shown, the pull-type component unlocking mechanism includes a housing 1, a sheet metal part 2, a spring 4 and a flexible pull ring 3. The flexible pull ring 3 is connected with the sheet metal part 2 through injection molding. The front part of the housing 1 A spring groove 5 is provided on both sides, and a spring 4 is respectively installed in the spring groove 5. The middle part of the housing 1 is provided with a limit groove 6 to limit the sliding range of the sheet metal part. The sheet metal part 2 is in a U-shaped structure. The inner side of the middle part of the metal part 2 is provided with a bending shrapnel 7, the bending shrapnel 7 is used to buckle the spring 4 in the component spring groove 5, and the tail of the sheet metal part is provided with an ear-shaped protrusion 8, the function of the ear-shaped protrusion 8 It is to limit the distance that the sheet metal part travels when it moves back and forth. There is a ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com