Hydraulic braking system of railway vehicle

A rail vehicle, hydraulic braking technology, applied in railway braking system, operating mechanism of railway vehicle brakes, hydrostatic brakes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The purpose of the present invention can be achieved through the following technical solutions:

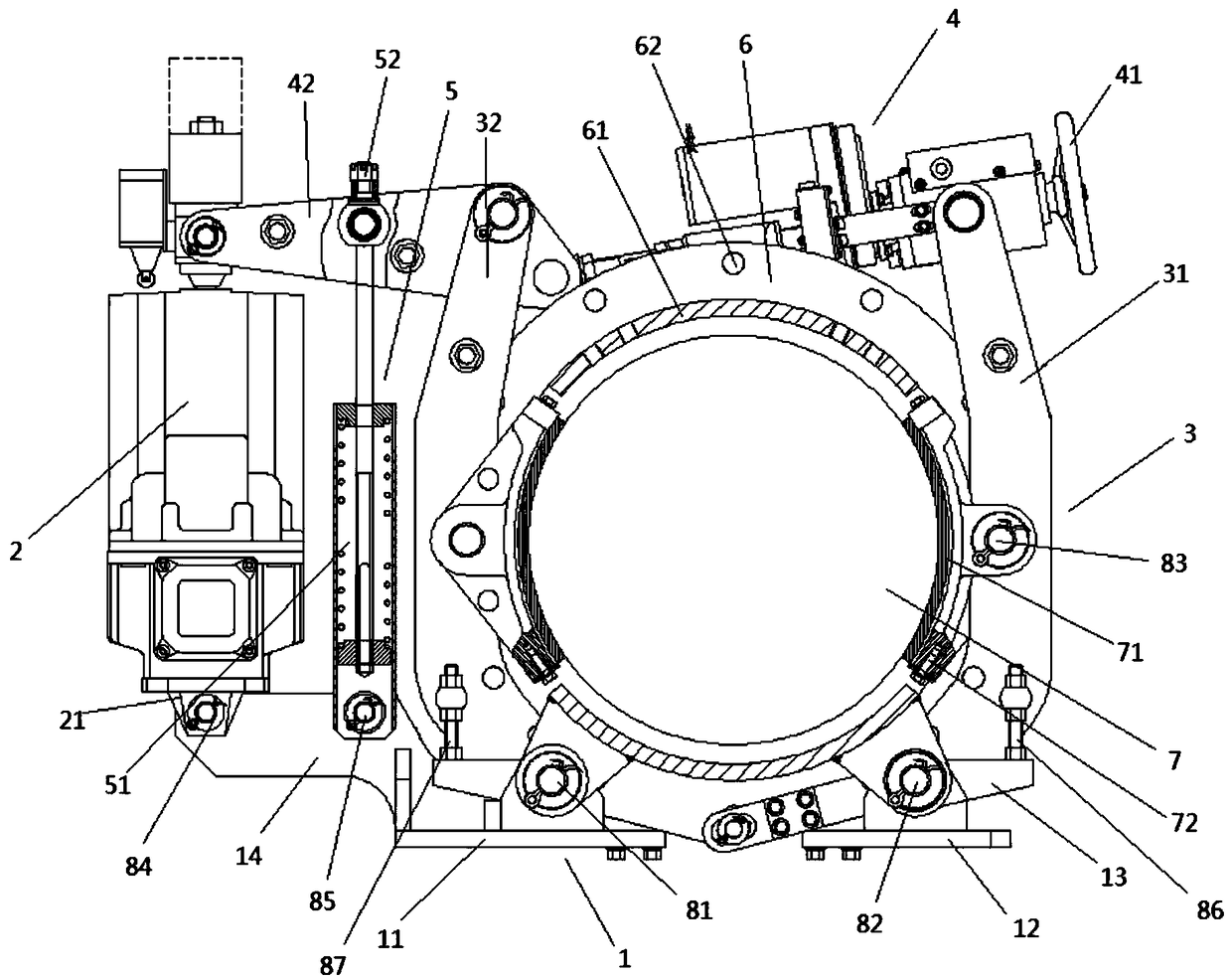

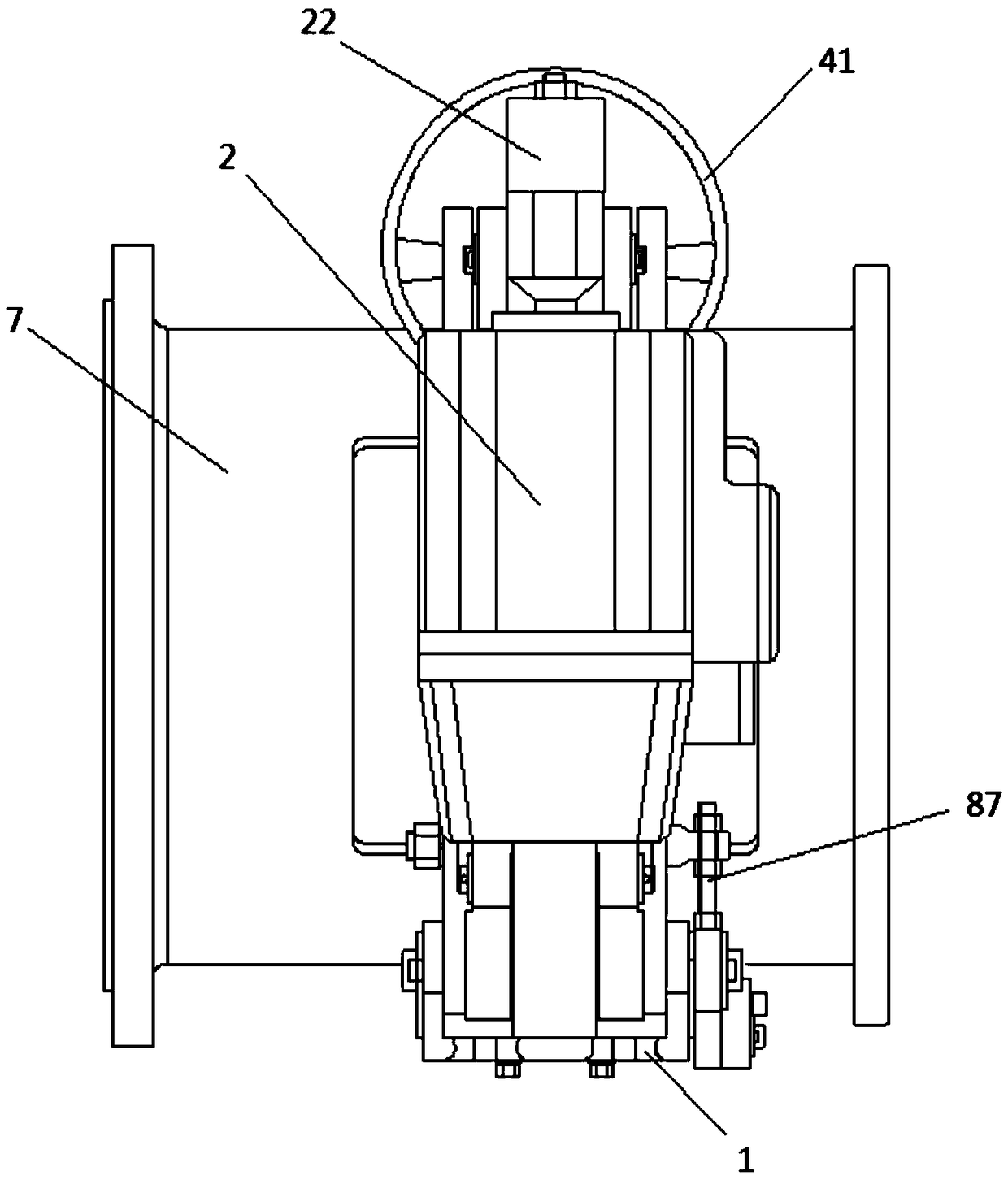

[0025] A hydraulic braking system for rail vehicles, see Figure 1-2 , including a brake frame 1, a frequency conversion pusher 2, a brake arm 3, a manual brake mechanism 4, a tie rod 5, a brake hub 6, and a brake mechanism 7;

[0026] The brake hub 6 is mounted on the outer bottom of the hub, and a brake mechanism 7 is installed on the inner side of the brake hub 6; a brake arm 3 is installed on the brake hub 6, and the top of the brake arm 3 is installed on the manual brake mechanism 4. The bottom end of the brake arm 3 is installed on the brake frame 1; the frequency conversion pusher 2 and the tie rod 5 are respectively installed between the brake frame 1 and the manual brake mechanism 4, and the two ends of the frequency conversion pusher 2 and the tie rod 5 are respectively Installed on the brake frame 1 and the manual brake mechanism 4;

[0027] Described brake fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com