Novel down hole drilling rig dust exhaust rubber-coupled molding curing dust suppression system

A technology of down-the-hole drilling rigs and glue joints, which is applied in chemical instruments and methods, separation methods, construction, etc., can solve the problems of reduced dust removal efficiency, equipment and air pollution hazards, and disappearance, so as to prolong the life of equipment, reduce equipment pollution, reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, the present invention will be further described.

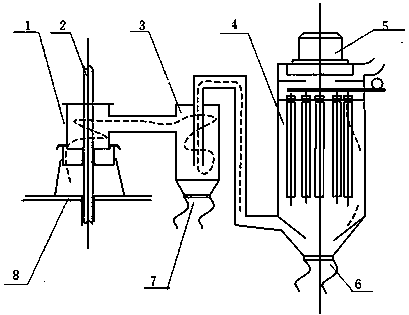

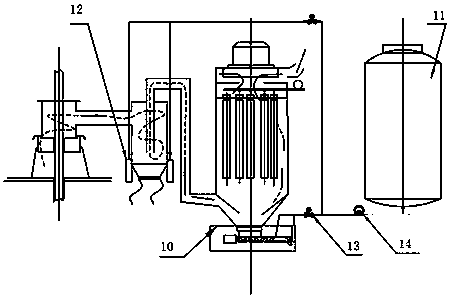

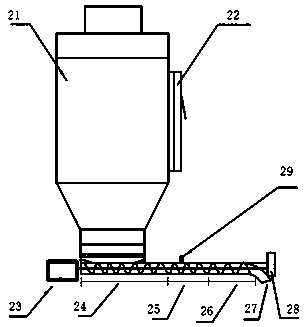

[0031] The technical scheme that this specific embodiment adopts is: see figure 2 As shown, it includes a dust collection cover 1, a settling chamber 3, a filter element dust collector 4, and a dust removal fan 5, and is characterized in that: the filter element dust collector 4 is provided with a dust collection box 21; on the side wall of the dust collection box 21 Equipped with back-blowing buffer filter chamber 22;

[0032] It also includes a forced-stirring adhesive dust removal mechanism 10 and an intelligent control dust-fixing mechanism; the forced-stirring rubber dust removal mechanism 10 is located at the tail of the filter element dust collector 4; the intelligent control dust-fixing mechanism is located in the settling chamber The dust outlet 7 of the filter element dust collector and the dust outlet 6 of the filter element dust collector; the forced stirring...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap