A Condenser Tube Layout Method with Low Condensation Resistance of Exhaust Steam

A condenser and resistance technology, applied in steam/steam condensers, lighting and heating equipment, etc., can solve the problems of insufficient use of steam to diffuse steam and low condensing pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and through implementation examples.

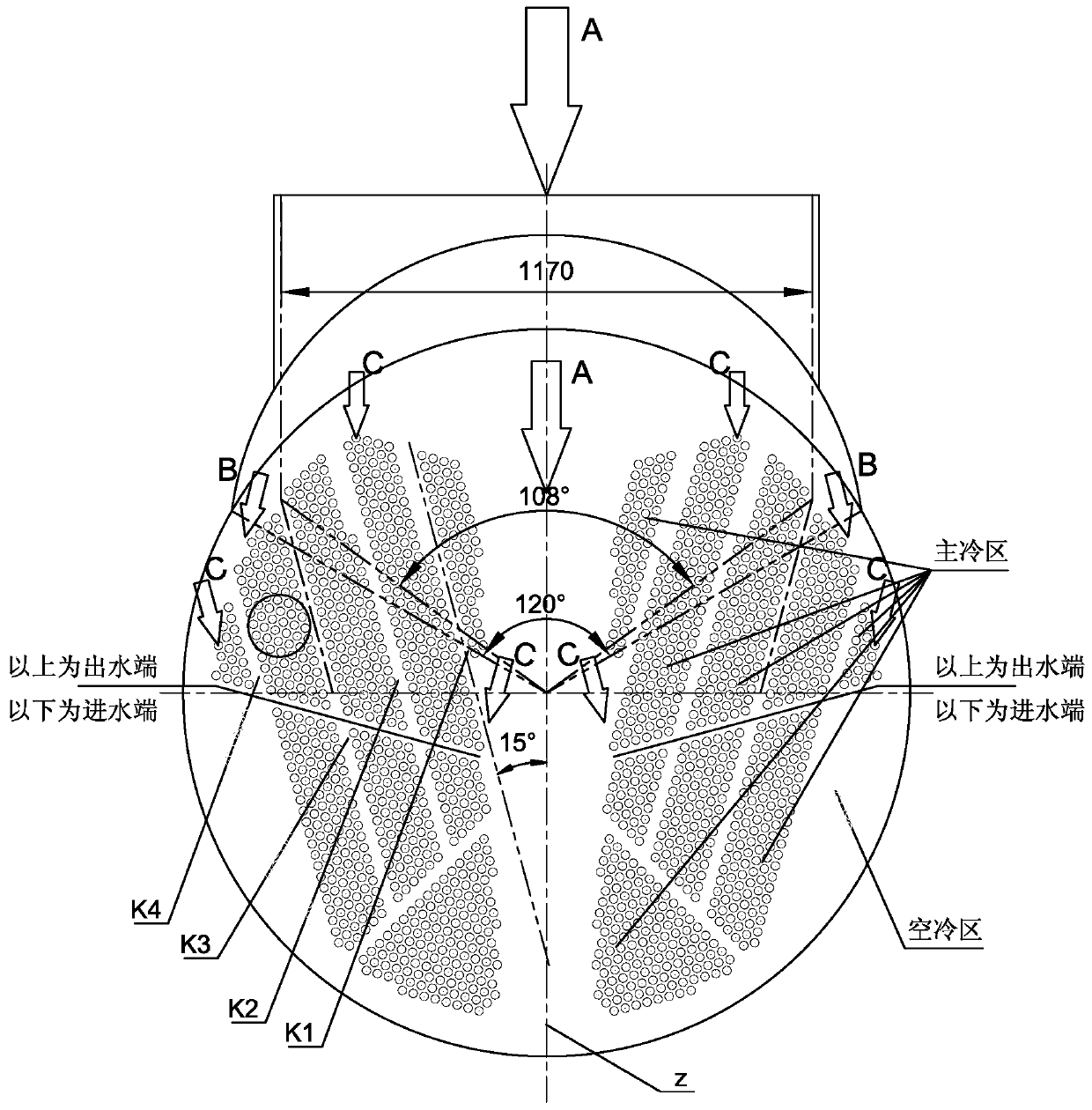

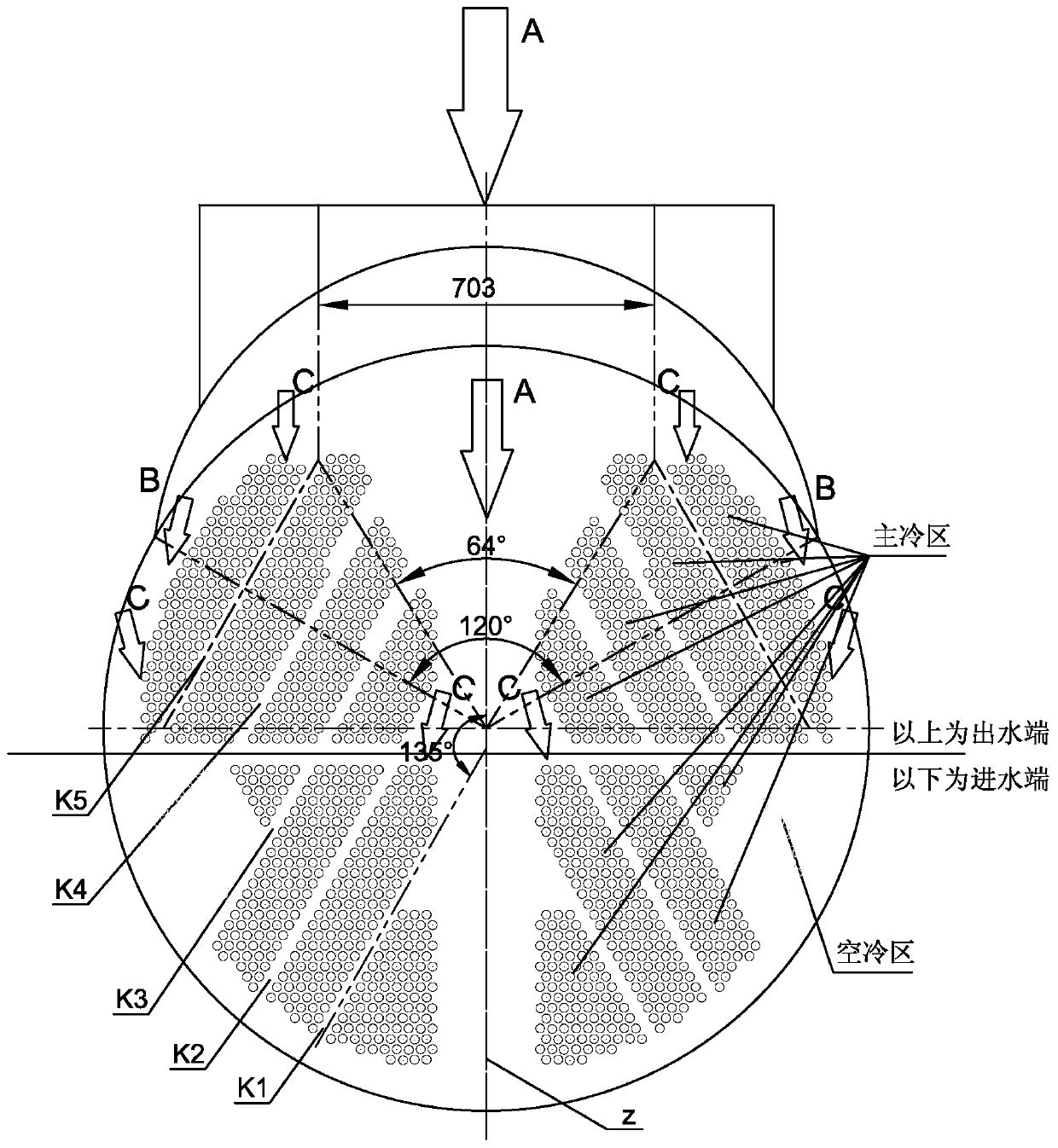

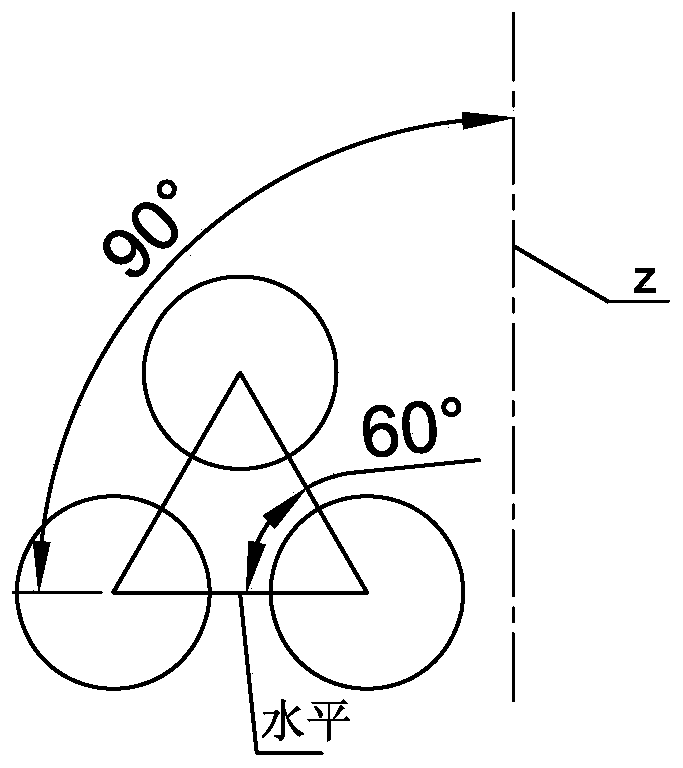

[0025] The pipe layout of the existing condenser (see figure 2 ), including 1656 tubes in the main cooling zone (i.e. heat exchange tubes) and 180 tubes in the air cooling zone, a total of 1836 tubes (these tubes form several tube bundles), as well as the water chamber diaphragm channel and the necessary diffusion tank, arranged in diameter In the tube sheet of 1.6 meters; the two ends of all the tubes are respectively fixed on the tube sheets at both ends of the condenser, and the steam inlet of the condenser is located at the top of the condenser. The tube bundles are distributed in a band shape with a bandwidth of 6 rows, and the adjacent tubes are arranged in an equilateral triangle ( image 3 shown), five diffusion tanks are required (diffusion tank axes are K1, K2, K3, K4, K5), and the outermost diffusion tank axis K5 can onl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com