A measuring device and method for describing fracture toughness of frp-concrete bonding surface

A technology of fracture toughness and measuring device, applied in the direction of measuring device, strength characteristics, and testing material strength by applying stable tension/compression, which can solve the problems of insufficient concrete tensile strength, fracture, and different measurement results of tip shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

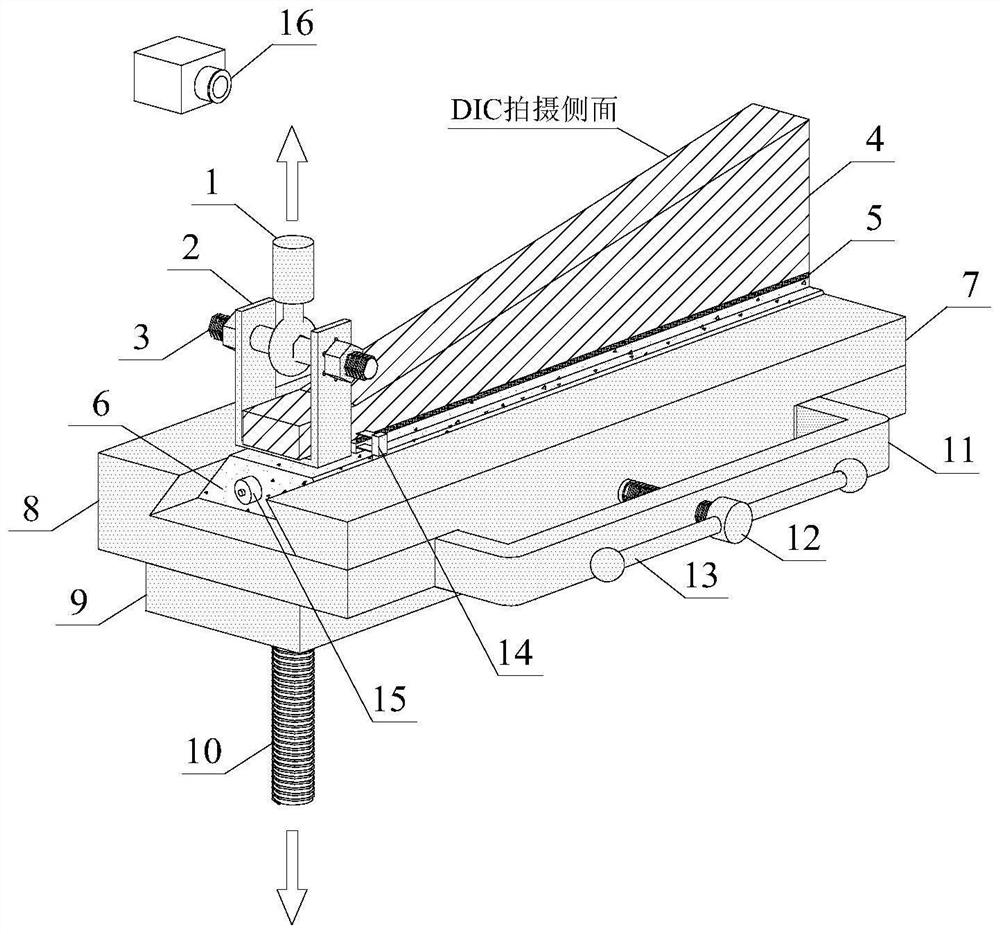

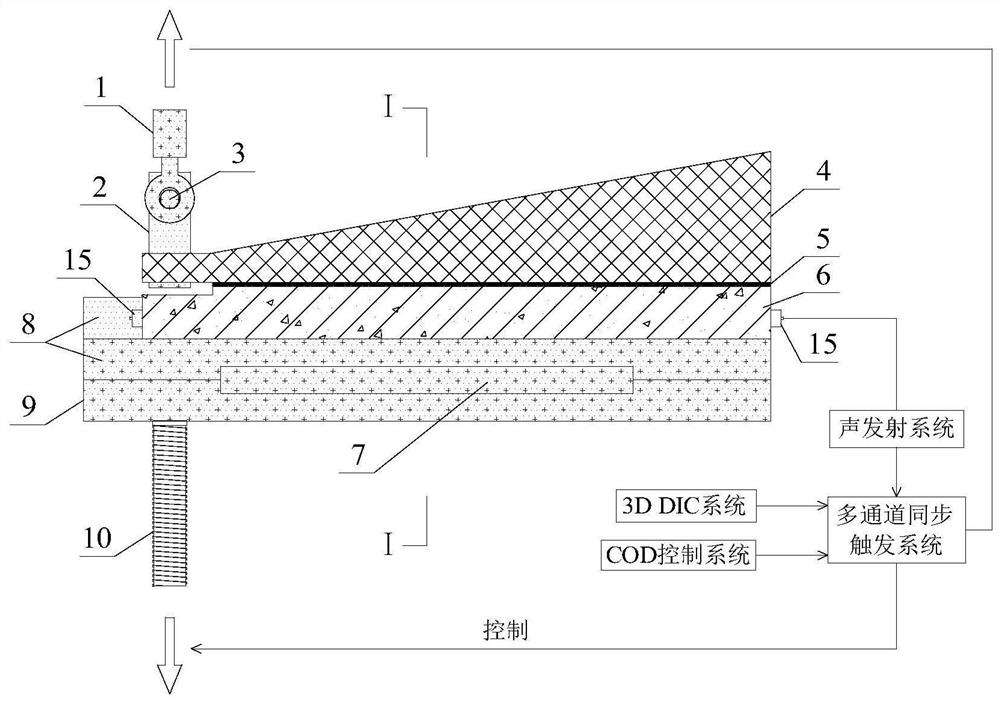

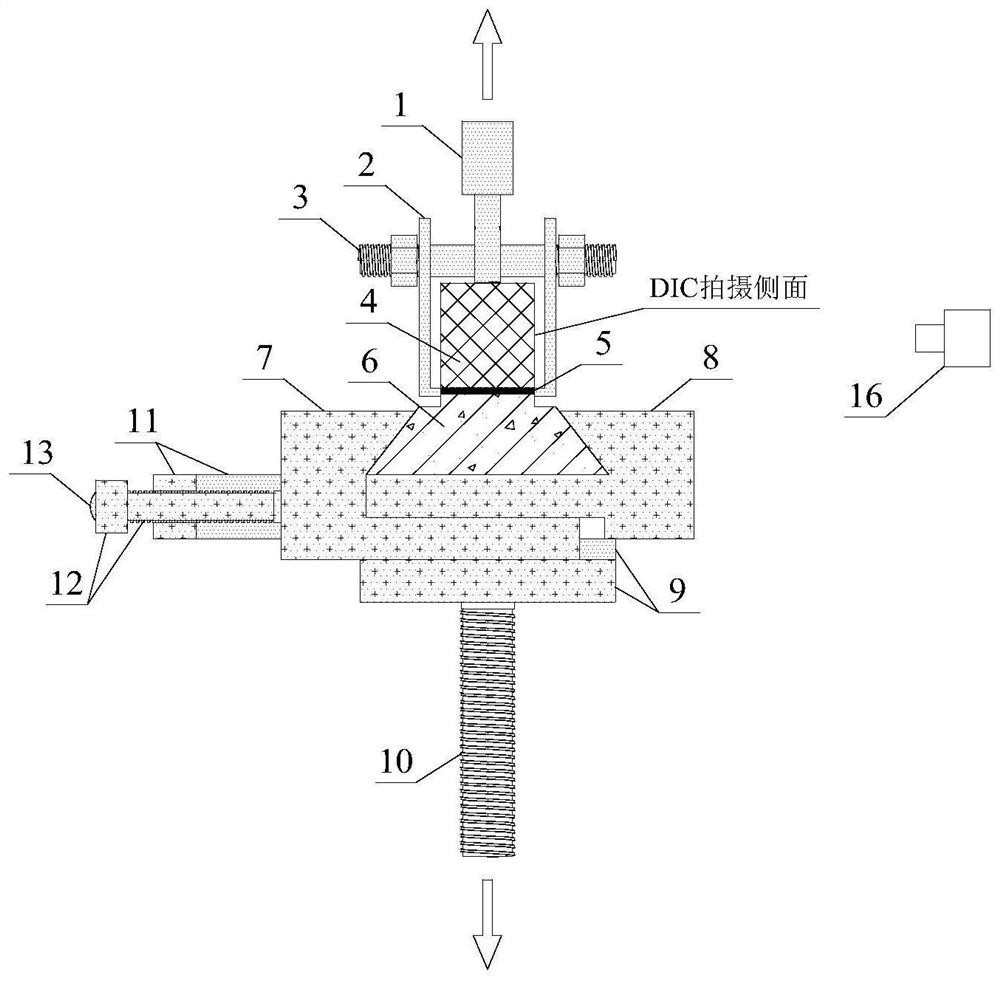

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

[0037] The invention provides a measuring device for describing the fracture toughness of the FRP-concrete bonded surface, comprising a fixing fixture, a specimen frame and a cantilever beam,

[0038] The specimen rack includes a bottom plate 9 placed in the axial direction, the upper surface of the bottom plate is fixedly connected with a fixed steel plate 8, the fixed steel plate 8 extends upward to limit the plate 8-1, and the fixed steel plate 8, the limit plate and the movable steel plate 7 are combined to form a jaw , a table-shaped concrete test piece 6 corresponding to the shape of the jaws is placed in the jaws, the upper surface of the table-shaped concrete test piece 6 is glued with a layer of FRP plate 5, and the upper surface of the FRP plate is covered with a cantilever beam 4; FRP in the present invention - There is no need to reserve cracks on the concret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com